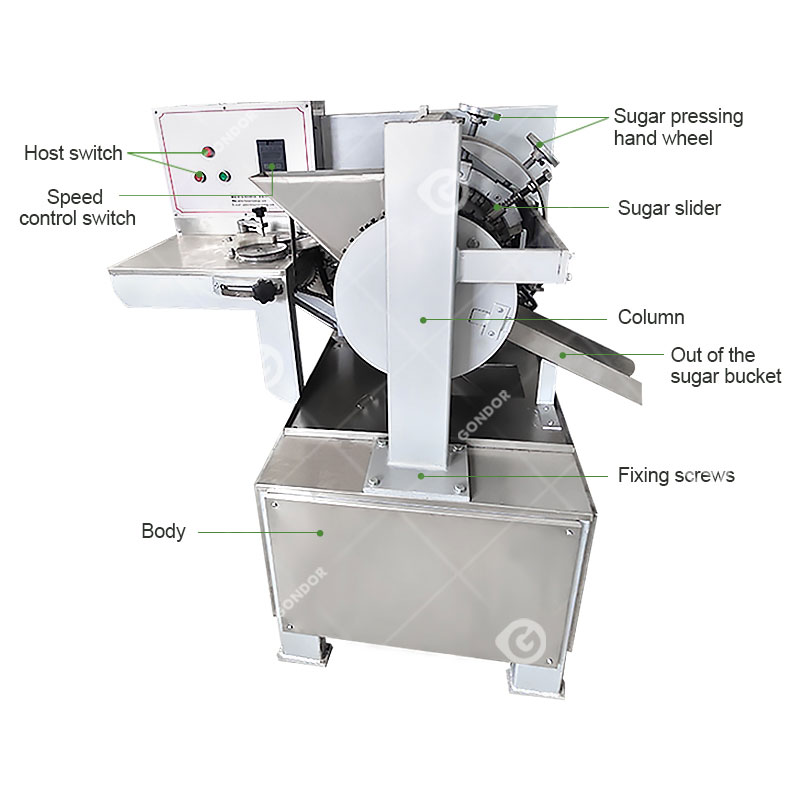

Ball Lollipop Forming Machine For Candy Production

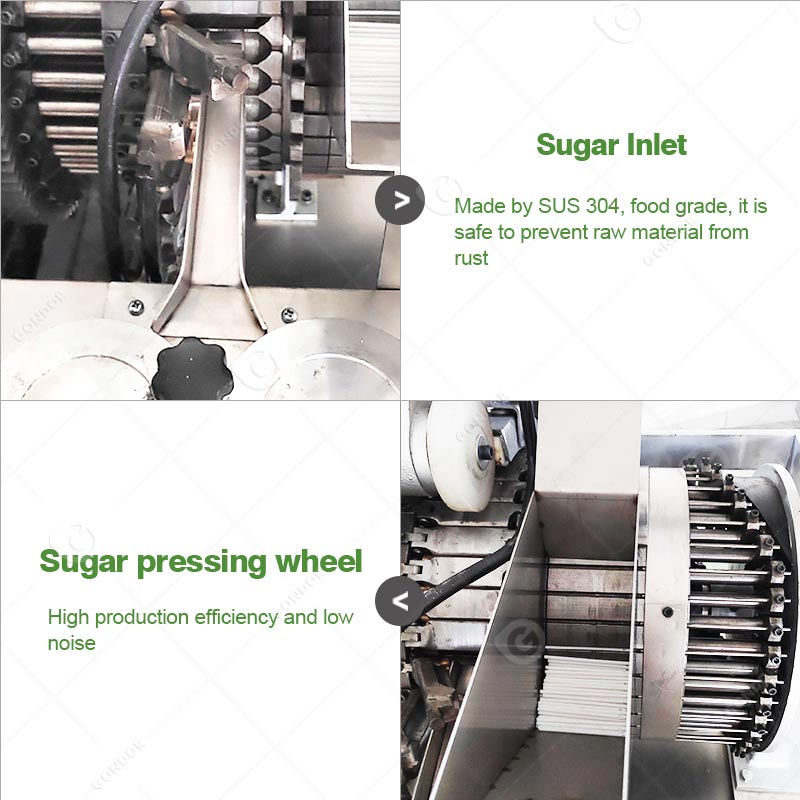

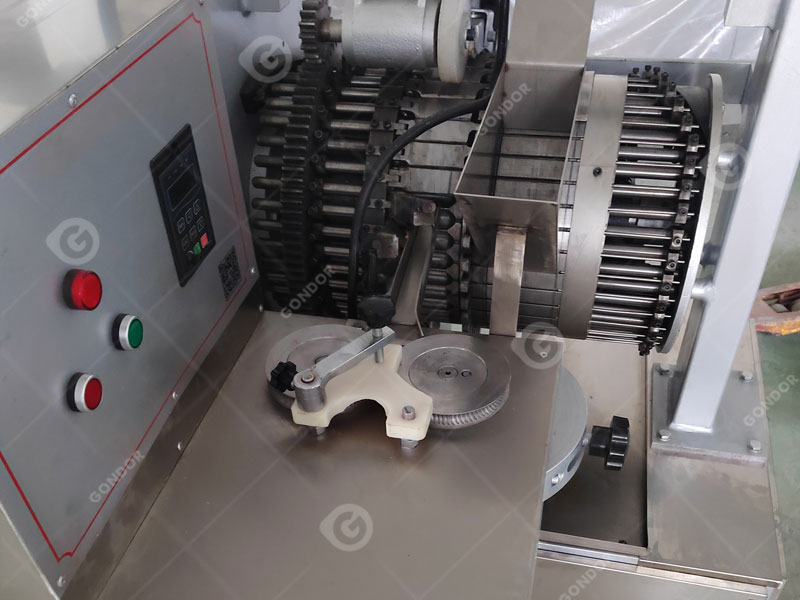

Ball lollipop candy forming making machine is a kind of equipment specially used for making lollipops. It usually consists of a control panel, a sugar wheel, a sugar inlet and a sugar pressing wheel. The forming machine has the characteristics of high automation, high production efficiency and stable product quality.

It can meet the needs of large-scale production of lollipops, and can produce lollipops of various shapes and flavors according to market demand.

ماكينة صنع مصاصة جوندور

Top View of Lollipop Forming Machine

Ball Lollipop Candy Forming Making Machine Specification

|

نموذج |

الحجم الخارجي | الجهد االكهربى | مسحوق | Candy size | Ball weight | سعة | وزن الآلة |

| جي دي-400 | 1000*900*1200مم | 220فولت/380 فولت | 1.5كيلوواط | 18-35مم | 6-18ز | 100-300kg/h 600-800pcs/min | 600كجم |

Ball Lollipop Forming Machine Application Industry

-

صناعة تصنيع المواد الغذائية

Various professional candy manufacturers use lollipop forming machines to mass-produce lollipops of various flavors and shapes.

-

صناعة الخبز

Some bakeries or chain baking brands may produce special lollipops as part of their products.

-

صناعة المطاعم

Some restaurants and dessert shops may make their own lollipops to provide unique dessert options.

-

Gift Industry

Customized lollipops are often used in holiday gifts or gift sets for special events.

-

Children's Food Industry

Companies that specialize in producing healthy and interesting lollipop products for children rely on this machine.

-

مناطق الجذب السياحي

Some tourist attractions sell lollipops with local characteristics or flavors.

Advantages of Choosing Gondor Lollipop Candy Making Machine

كفاءة إنتاجية عالية

Lollipops can be produced quickly and in large quantities to meet the needs of large-scale production.

النظافة والسلامة

Effectively avoid possible contamination during manual production and ensure the sanitary quality of the product.

براعة

By simply and conveniently changing the mold, you can efficiently produce a variety of unique lollipops in different shapes.

Improved Production Capacity

The production capacity of some production lines can reach hundreds of kilograms per hour.

درجة عالية من الأتمتة

The candy block molding and stick insertion can be integrated, reducing manpower input and relatively easy to operate.

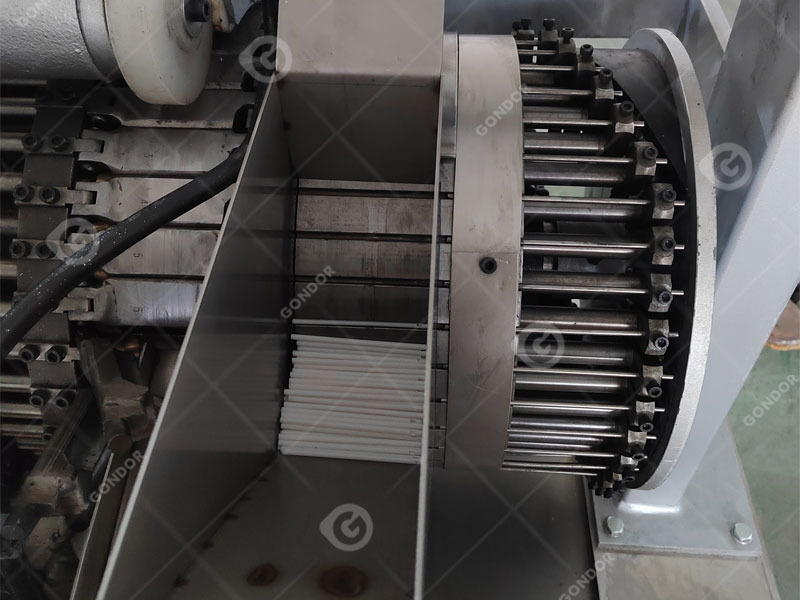

جودة مستقرة

The extrusion and molding process can be accurately controlled to make the shape and size of the lollipops consistent and the quality more stable.

Good Equipment Stability

By adopting special design and material selection, it can significantly reduce the wear of parts in production and extend the service life of equipment.

The Working Principle of Spherical lollipop Candy Forming Machine

Through the continuous rotary process of “sugar bar → cutting into sections → die closing and stamping + rod insertion → cooling → demolding → output”, the spherical lollipop forming machine realizes high-speed, low-waste sugar, regular shape and centered rod automated production.

Gondor Ball Lollipop Candy Forming Making Machine – The Magic Key to Starting a Sweet Career

If you want to start a sweet business, choose our lollipop forming machine! It is the perfect combination of efficiency and innovation, with excellent production efficiency, and can quickly meet the large market demand. Choose Gondor’s lollipop forming machine to give wings to your sweet dream and create unlimited possibilities!