ماكينة تصنيع الشوكولاتة جوندور

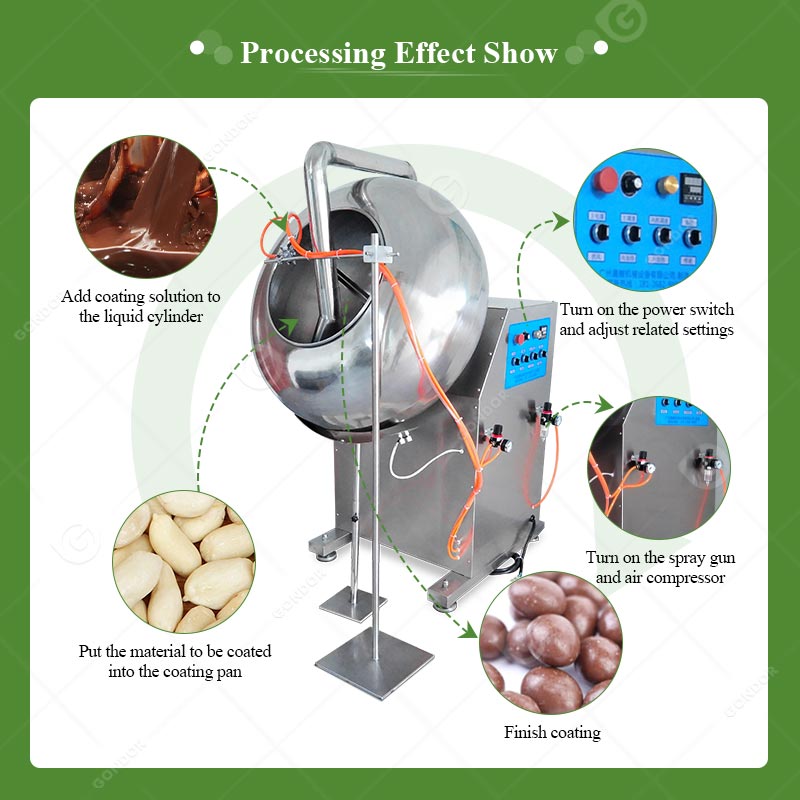

ماكينة حلوى الشوكولاتة هي معدات مهمة تستخدم خصيصًا لطلاء الأقراص, حبوب, إلخ. علاوة على ذلك, آلة الطلاء لديها مجموعة واسعة من الاستخدامات. في المجال الصيدلاني, يمكنه تحسين طعم الأدوية والتحكم في إطلاق الدواء. في صناعة المواد الغذائية, يمكن أن تجعل الحلوى أكثر جمالا ولذيذة. فضلاً عن ذلك, القدرة الإنتاجية الفعالة يمكن أن تلبي الاحتياجات واسعة النطاق, ويوجد تعديل مرن لدرجة الحرارة للتكيف مع مواد الطلاء المختلفة.

ماكينة طلاء حلوى جوندور

مواصفات آلة طلاء الشوكولاتة

| نموذج | قطر الوعاء | سرعة الدوران | قوة المحرك الرئيسي | قوة المنفاخ | قوة سلك التدفئة | إنتاجية | البعد | الوزن الصافي |

| GDJ-400A | 400مم | 50دورة في الدقيقة | 0.37كيلوواط | 40دبليو | 1كيلوواط | 2-5كجم/دفعة | 770*670*840مم | 70كجم |

| GDJ-600A | 600مم | 0.75كيلوواط | 120دبليو | 2كيلوواط | 8-15كجم/دفعة | 930*620*1140مم | 120كجم | |

| GDJ-800A | 800مم | 1.5كيلوواط | 200دبليو | 2كيلوواط | 30-50كجم/دفعة | 1100*800*1600مم | 180كجم | |

| GDJ-1000A | 1000مم | 2.2كيلوواط | 250دبليو | 4كيلوواط | 50-70كجم/دفعة | 1200*1200*1600مم | 260كجم | |

| GDJ-1250A | 1250مم | 2.2كيلوواط | 370دبليو | 4كيلوواط | 80-150كجم/دفعة | 1350*1350*1600مم | 360كجم |

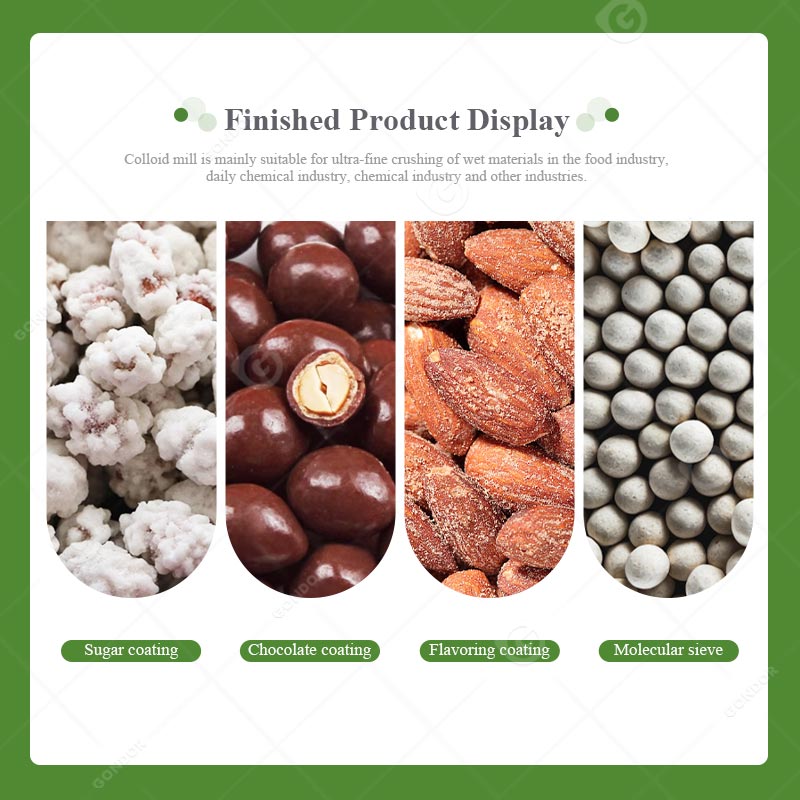

يتم استخدام آلة تقطيع الحلوى جوندور على نطاق واسع في الأسواق التالية

منتج آلة طلاء الحلوى جوندور

المنتج النهائي لطلاء الحلوى من جوندور

نكهات مختلفة من الفول السوداني

كرات الشوكولاتة

مزايا اختيار آلة تحميص الشوكولاتة جوندور

يمكنها تحقيق التشغيل المستمر وتحسين كفاءة الإنتاج.

مع وظائف التدفئة الداخلية والخارجية لتلبية متطلبات مواد الطلاء المختلفة.

منع تطاير الغبار وتطاير سائل الطلاء, ضمان نظافة بيئة الإنتاج واستخدام المواد.

القدرة على ضبط حجم الرش وتوزيع محلول الطلاء بدقة لضمان توحيد الطلاء.

توجد نماذج بسعات وأحجام مختلفة لتلبية احتياجات الإنتاج بمقاييس مختلفة.

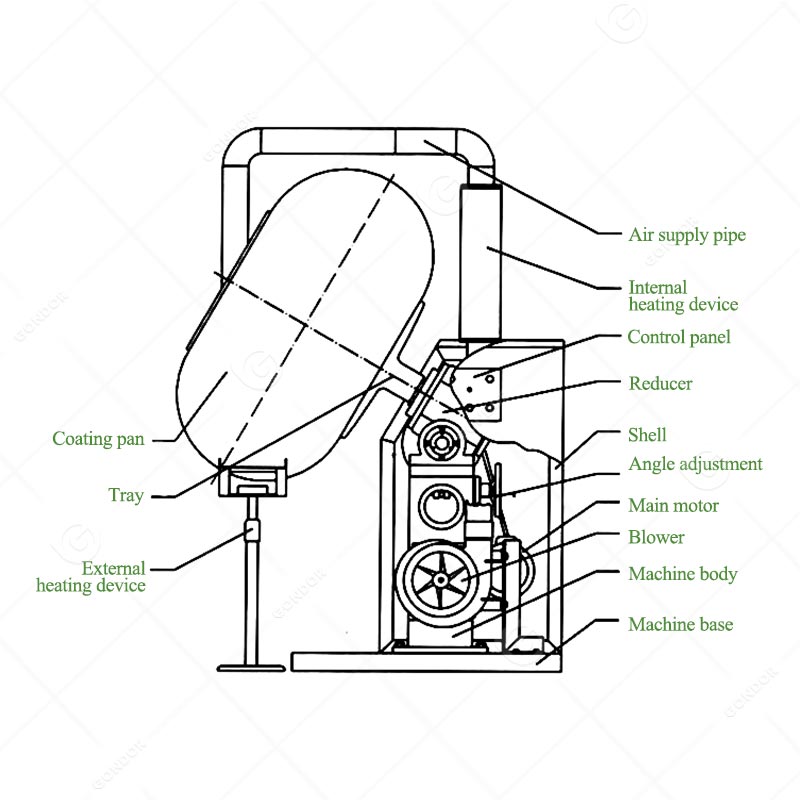

مكونات ووظائف آلة تحضير الشوكولاتة

طلاء عموم

عادة كروية, على شكل كمثرى, أو مقلاة من الفولاذ المقاوم للصدأ على شكل طبلة. يمكن إمالته بزوايا متعددة للتحكم في مسار التدحرج ودرجة خلط المواد. إن دورانها هو الآلية الأساسية لتوليد الحركة المعقدة للمواد.

نظام الرش:

يشمل خزان الطين, مضخة, الأنابيب, وفوهات الرش. مسؤول عن تفتيت سائل الطلاء مثل الشوكولاتة والشراب بالتساوي, ضمان طلاء قطرات غرامة على الحلوى.

نظام إمداد الهواء:

تحتوي على مروحة, سخان, جهاز التبريد, فلتر الهواء, وقناة الهواء. يوفر درجة حرارة يمكن التحكم فيها (حار أو بارد) والهواء النظيف لتجفيف أو تبريد طبقة الطلاء.

نظام التحكم:

تستخدم آلات الطلاء الحديثة عادةً التحكم PLC أو الكمبيوتر.

يمكن للمشغلين ضبط المعلمات بدقة مثل سرعة دوران المقلاة, درجة حرارة, وقت الرش, ووقت التجفيف لتحقيق مؤتمتة بالكامل, إنتاج قابل للتكرار.

نظام إزالة الغبار:

يعمل مدخل الهواء الموجود أعلى المقلاة على إزالة الغبار والرطوبة المتولدة أثناء عملية الطلاء, الحفاظ على بيئة عمل نظيفة.

ماكينة تصنيع حلوى الشوكولاتة جوندور – مصنع عالي الجودة

التعاون مع جوندور لماكينات طلاء الحلوى, سوف تستمتع بالمزايا التالية: الدعم الفني المتقدم يضمن طلاء موحد ومستقر. تساعدك كفاءة الإنتاج العالية على زيادة الإنتاج وتلبية طلب السوق. خدمة ما بعد البيع عالية الجودة تسمح لك بعدم القلق. اتخذ إجراءً الآن وابدأ فصلًا جديدًا من الطلاء مع جوندور!