مقدمة عن خط إنتاج الحلوى الصلبة المشكلة بالقالب جوندور

إذا كنت تبحث عن حل فعال وموثوق, إن خط إنتاج تشكيل القوالب الأوتوماتيكي للحلوى الصلبة هو خيارك المثالي. كخط إنتاج الحلوى الصلبة المتقدمة, فهو يدمج الطبخ بالفراغ, التلوين/النكهة التلقائية, وتكنولوجيا خط إنتاج الحلوى ذات القوالب الدقيقة لتلبية المتطلبات التجارية كبيرة الحجم بسهولة.

نماذج خط إنتاج الحلوى الصلبة المشكلة بالقالب من جوندور

لتلبية احتياجات مستويات الإنتاج المختلفة, نحن نقدم نماذج مختلفة من خطوط إنتاج الحلوى المشكلة بالقالب. إذا كان لديك أي متطلبات أخرى, يرجى الاتصال بنا وسنقدم لك الاستشارة والاقتباس المجاني.

| نموذج | YT200 | YT400 | YT1000 |

| سعة | 150كجم/ساعة | 300كجم/ساعة | 600-1000كجم/ساعة |

| وزن الحلوى | حسب حجم الحلوى | ||

| سرعة الإيداع | 500جهاز كمبيوتر شخصى / دقيقة | 1000جهاز كمبيوتر شخصى / دقيقة | 2000-4000جهاز كمبيوتر شخصى / دقيقة |

| متطلبات البخار | 200كجم/ساعة, 0.5-0.8mpa | 300كجم/ساعة, 0.5-0.8mpa | 400-600كجم/ساعة, 0.5-0.8mpa |

| حالة العمل | درجة الحرارة 20 درجة مئوية -25 درجة مئوية; رطوبة<55% | ||

| الطاقة الكهربائية اللازمة | 3018كيلووات/380 فولت/50 هرتز | 18كيلووات/380 فولت/50 هرتز | 45-60كيلووات/380 فولت/50 هرتز |

| الطول الإجمالي | 16م | 12م | 60كيلوواط/380 فولت/50 هرتز |

| وزن الآلة | 4500كجم | 8000كجم | 10000-15000كجم |

التطبيقات الصناعية لخطوط إنتاج الحلوى الصلبة المشكلة بالقالب جوندور

يعد خط إنتاج الحلوى على شكل قالب حلاً متعدد الاستخدامات يستخدم في مختلف القطاعات. أبعد من الحلويات التقليدية, يتم استخدامه بشكل متزايد في الصناعات الصحية والصيدلانية بسبب دقته وكفاءته.

1. صناعة الحلويات التقليدية

هذا هو القطاع الرئيسي لآلات صنع الحلوى الصلبة, التركيز على الحلويات الاستهلاكية في السوق الشامل:

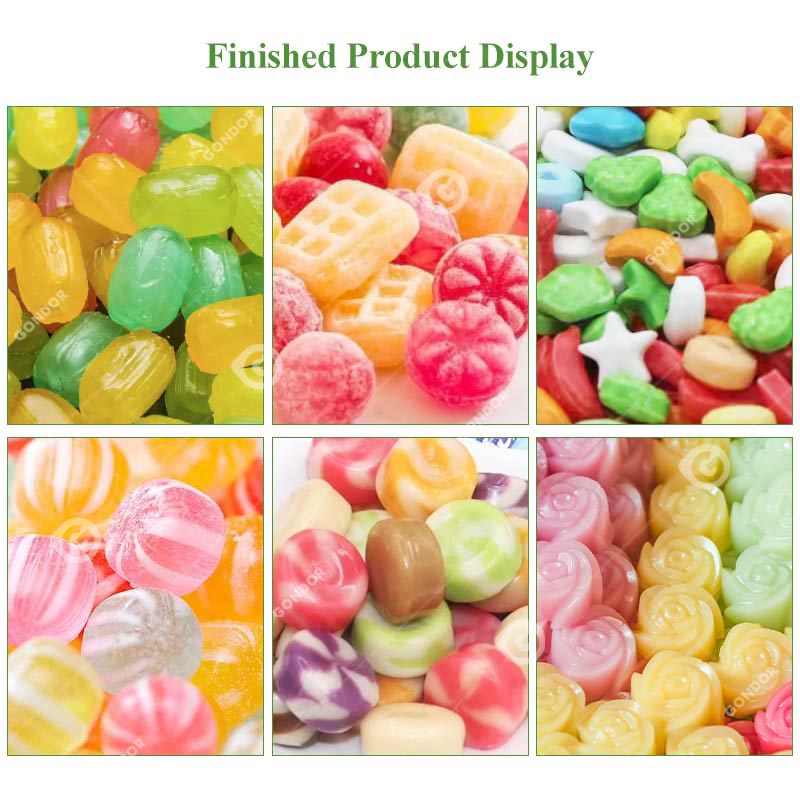

- الحلوى الصلبة بنكهة الفاكهة: لون واحد, مزدوج اللون, أو حلوى مخططة متعددة الألوان.

- الحلوى المملوءة بالمركز: استخدام تكنولوجيا خط إنتاج الحلوى الصلبة المتقدمة لحقن المربى, شوكولاتة, أو مسحوق في قلب الحلوى.

- النعناع & معطرات التنفس: نعناع عالي الكثافة يتطلب السلامة الهيكلية التي يوفرها التشكيل بالقالب.

- مصاصات على شكل قالب: يمكن للخطوط المتخصصة إدخال العصي تلقائيًا أثناء عملية تشكيل المصاصات الكروية أو ثلاثية الأبعاد.

2. صناعة المكملات الغذائية

تعتبر خطوط إنتاج الحلوى الصلبة المقولبة مثالية “الحلوى الوظيفية” لأنها تضمن الوزن الدقيق وتوزيع المكونات:

- معينات الحلق: معينات الحلق التي تحتوي على زيت المنثول والأوكالبتوس.

- المكملات الغذائية: المنتجات القائمة على الحلوى والتي تسهل على الأطفال وكبار السن تناول الفيتامينات والمعادن.

- المكونات الوظيفية: الحلوى الصلبة المدعمة بالبروبيوتيك, اللوتين أو الألياف الغذائية.

3. المكونات الغذائية & المعالجة الصناعية

- الخبز & إضافات الحلوى: إنتاج أشكال معينة أو قطع حلوى مطحونة لتزيين الكيك والآيس كريم.

- العلامات التجارية للشركات: أشكال مخصصة أو حلوى مزخرفة بالشعار للفنادق, شركات الطيران, وهدايا الشركات.

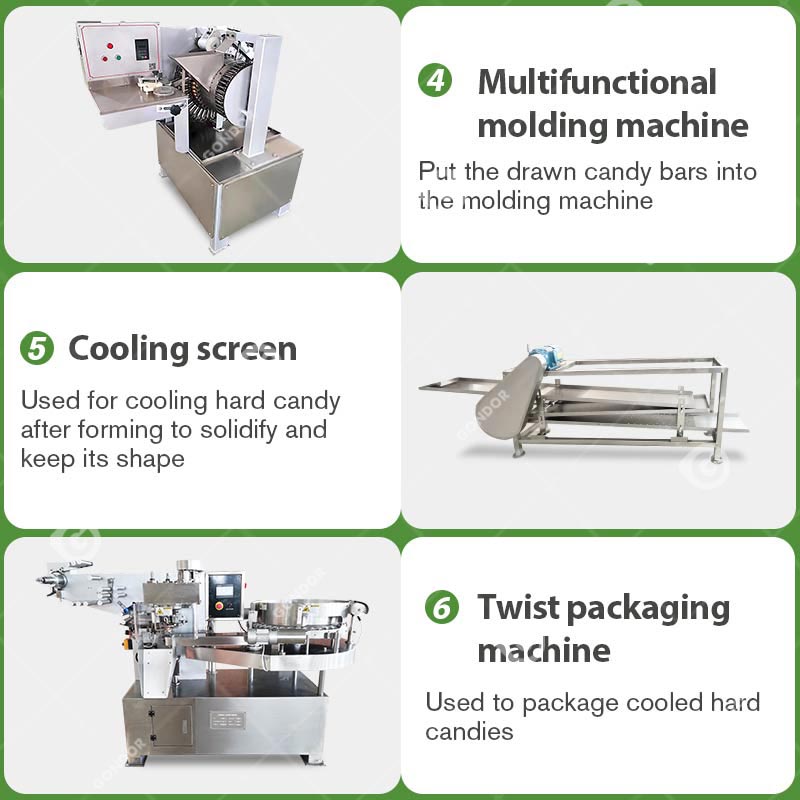

سير عمل خط إنتاج الحلوى الصلبة المقولبة

يحقق خط الإنتاج هذا أتمتة عالية من معالجة المواد الخام إلى التعبئة النهائية. العملية المحددة هي كما يلي:

يضيف المشغلون الماء والمكونات إلى وعاء الطبخ المغلف وتسخينها إلى درجة حرارة عالية محددة مسبقا. يضمن التحكم الدقيق في درجة الحرارة وصول الشراب إلى اللزوجة المثالية ومحتوى الرطوبة.

يتم سكب كتلة الحلوى المطبوخة على طاولة التبريد للتبريد المادي. خلال هذه المرحلة, يقوم المشغلون بطي الكتلة ودمج النكهات بالتساوي, الألوان, وغيرها من الإضافات.

يتم وضع كتلة الحلوى المرنة في أسطوانة الدفعة لتشكيل حبل سميك, والذي يقوم بعد ذلك بإدخال حجم الحبل تلقائيًا ليتم تمديده إلى حبل رفيع متسق, ضمان وزن موحد لكل قطعة حلوى.

يدخل الحبل الرفيع إلى آلة تشكيل الحلوى الصلبة, حيث يتم قطعها وضغطها على الفور إلى أشكال محددة مسبقًا بواسطة قوالب دوارة عالية السرعة, ضمان ملامح حادة وأنماط رائعة.

تدخل الحلوى المشكلة حديثًا إلى خزانة التبريد. من خلال تعميم الهواء البارد, يتم تبريد الحلوى وتثبيتها بسرعة بينما يتم فحص الأجزاء الصغيرة.

يتم تغذية الحلوى المستقرة في آلة التعبئة الملتوية, الذي يكمل التعبئة تلقائيًا, ختم ملتوي, والقطع. تصبح المنتجات النهائية جاهزة للتخزين.

هل يمكن لخط الإنتاج هذا أن يصنع المصاصات?

نعم, يمكن لخط الإنتاج هذا إنتاج المصاصات. من خلال تكوين المتخصصة آلة تشكيل المصاصة داخل الخط, فهو يتيح إنتاجًا متوافقًا لكل من الحلوى الصلبة والمصاصات. أثناء عملية تشكيل القالب اللحظية, يقوم الجهاز تلقائيًا بمزامنة “إدراج العصا” خطوة, زرع العصي البلاستيكية أو الورقية بدقة في وسط كتلة الحلوى. سواء كان شكل كروي كلاسيكي, قرص مسطح, أو أشكال ثلاثية الأبعاد معقدة, تضمن عملية التشكيل بالقالب خطوطًا دقيقة وختمًا آمنًا. هذا “متعددة الأغراض” لا تؤدي القدرة على زيادة تنوع المنتجات فحسب، بل توفر أيضًا للعملاء مرونة كبيرة للتبديل بين أسواق الحلوى الصلبة والمصاصات.

مميزات خط إنتاج الحلوى الصلبة المشكلة بالقالب جوندور

- أتمتة عالية & التخصيص: عملية مؤتمتة بالكامل بدءًا من الطهي وتحجيم الحبال وحتى التشكيل. نحن ندعم تخصيص العملاء لأشكال الحلوى المحددة, الأحجام, وتخطيطات المصنع.

- الهندسة الدقيقة: يستخدم وعاء الطبخ المغطى للطهي بالفراغ وآلة تشكيل المصاصة عالية السرعة لضمان قوام كثيف ومظهر رائع للحلوى.

- حلول التعبئة والتغليف المتكاملة: يشتمل على نظام تعبئة ملتوي كامل وحل فرز, تمكين الانتقال السلس من الإنتاج إلى التعبئة والتغليف الجاهزة للبيع بالتجزئة.

- ضمان عالمي لما بعد البيع: ضمان لمدة عام مع فحوصات ثلاثية قبل الشحن. نحن نقدم مقاطع فيديو تعليمية متعددة اللغات, تسليم قطع الغيار UPS, ودعم المهندسين في الخارج في الموقع.

- لوجستيات سلسة: حتى بدون خبرة جمركية, نحن نقدم شحنًا موثوقًا من الباب إلى الباب عبر البحر, هواء, أو صريحة لضمان شراء خالي من القلق.