مقدمة خط غسيل بيض جوندور

تعتبر غسالة البيض حلاً احترافيًا مصممًا لتنظيف ومعالجة كميات كبيرة من البيض, مما يجعلها مثالية لمزارع الدواجن, مصانع المواد الغذائية, وموردي البيض. الخط مزود بخزان مياه, الحزام الناقل, نظام الرش, فرش, وقسم تجفيف لإزالة الأوساخ تمامًا, البراز, والبكتيريا من سطح قشر البيض.

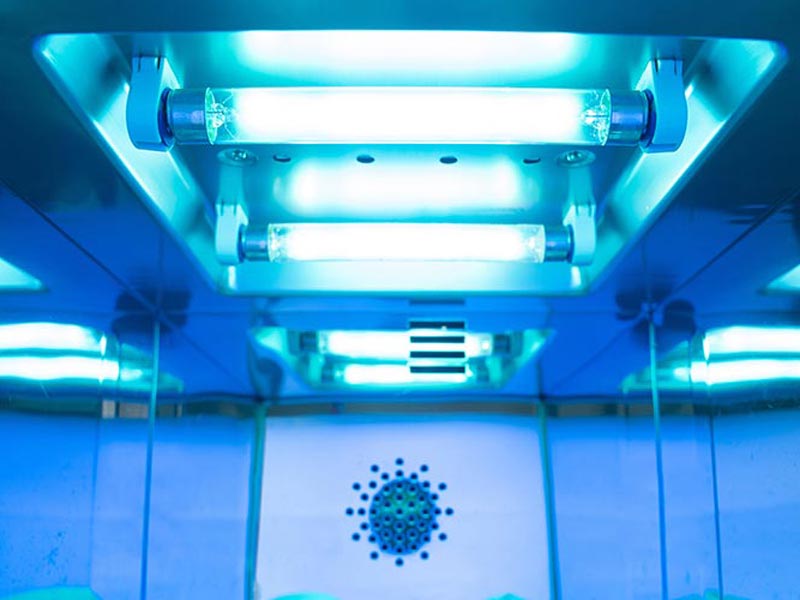

أثناء العملية, يتم إدخال البيض تلقائيًا في الخط ويمر عبر النقع, رش, وتمشيط لطيف للتنظيف العميق. ثم يتم تجفيفها بالهواء مع الدورة الدموية الدافئة, يتم فحصها بالكشف البصري لإزالة البيض المتصدع أو المعيب, ويمكن تعقيمها بشكل أكبر. أخيراً, يمكن تصنيف البيض وتعبئته, التأكد من أنها صحية, آمن, وجاهزة للتوزيع في الأسواق.

معلمات خط إنتاج غسيل بيض جوندور

| اسم المنتج | مزود الطاقة | إمدادات الهواء | إخراج المعدات |

| ماكينة تحميل البيض | مصدر طاقة مساعد DC24V, 60دبليو | 0.6MPa, 10لتر/دقيقة | 2,700 – 20,000 بيضة/ساعة, سرعة قابلة للتعديل |

| ماكينة ترتيب البيض

(منفذ أفقي واحد) |

مصدر طاقة مساعد DC24V, 60دبليو | الحد الأقصى 10,800 بيضة/ساعة, سرعة قابلة للتعديل | |

| ماكينة ترتيب البيض | مصدر طاقة مساعد DC24V, 60دبليو | الحد الأقصى 5,400 – 16,200 بيضة/ساعة, سرعة قابلة للتعديل | |

| ماكينة جمع البيض | مصدر طاقة مساعد DC24V, 60دبليو | 2,700 – 20,000 بيضة/ساعة, سرعة قابلة للتعديل | |

| غسيل البيض المتكامل,

آلة التجفيف والفحص البصري (بما في ذلك مصباح الأشعة فوق البنفسجية) |

تيار متردد 220 فولت, 1الرقم الهيدروجيني (1 مرحلة), 1.7كيلوواط | الحد الأقصى 5,400 – 16,200 بيضة/ساعة, سرعة قابلة للتعديل | |

| آلة وحدات

(غسل البيض, التجفيف والفحص البصري اختياري) |

تيار متردد 220 فولت, 1الرقم الهيدروجيني (1 مرحلة), 0.15 – 1.5كيلوواط | الحد الأقصى 5,400 – 16,200 بيضة/ساعة, سرعة قابلة للتعديل |

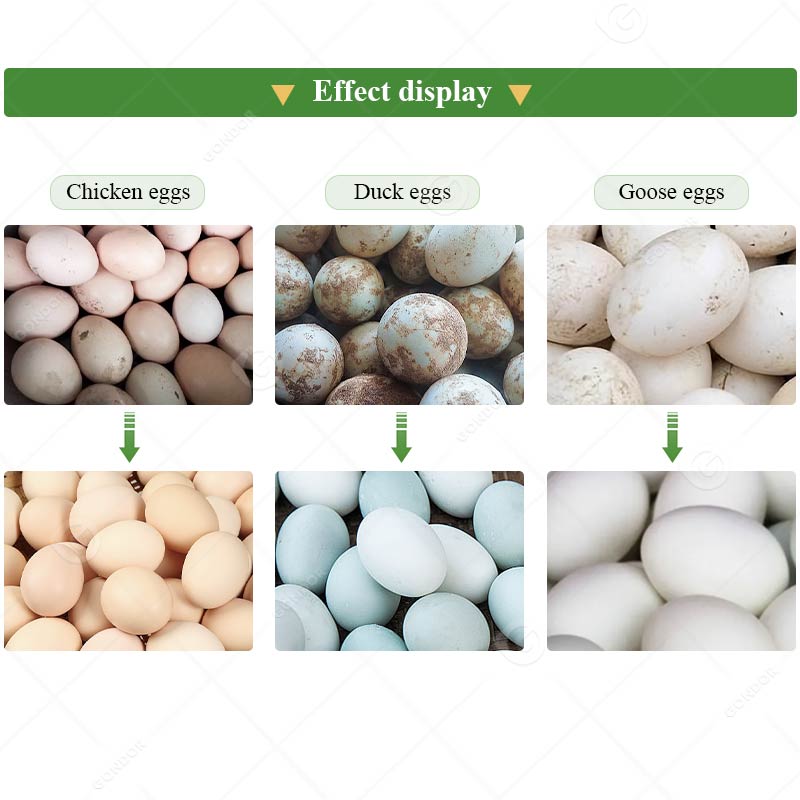

تطبيق خط إنتاج غسل وتجهيز بيض جوندور

يعتبر خط تنظيف البيض هذا مثاليًا لمزارع الدواجن, موردي البيض, مصانع تجهيز الأغذية, محلات السوبر ماركت, والمطابخ المركزية. يمكنها معالجة بيض الدجاج, بيض البط, وغيرها من بيض القشرة المشابهة, مما يجعلها نظيفة وجافة للتغليف أو مزيد من المعالجة.

هيكل خط معالجة بيض جوندور

مصممة لمعالجة البيض بشكل احترافي, يجمع هذا الخط المتكامل 304 هيكل من الفولاذ المقاوم للصدأ, تنظيف لطيف وفعال, ومراقبة الجودة متعددة المراحل لضمان السلامة, بيض عالي الجودة مع سير عمل مبسط.

ميزات معدات معالجة بيض جوندور

- تصميم متكامل: الغسيل والتجفيف في وحدة واحدة مدمجة, توفير المساحة والعمل.

- تنظيف لطيف: تعمل بكرات الفرشاة الناعمة ورذاذ الماء على تجنب تلف البيض.

- تجفيف فعال: يضمن نظام الهواء الدافئ تجفيفًا سريعًا وموحدًا.

- المعيار الصحي: مصنوعة من الفولاذ المقاوم للصدأ, سهلة التنظيف والصيانة.

- توفير الطاقة: مجهزة بإعادة تدوير المياه وتسخين الهواء الأمثل.

المعدات الداعمة الموصى بها لخط إنتاج تنظيف وتجهيز البيض

لبناء ورشة عمل أكثر كفاءة لمعالجة البيض ذات العملية الكاملة, يمكن مطابقة معدات الدعم الأساسية التالية:

من خلال التكامل السلس لخط إنتاج تنظيف وتجهيز البيض مع المعدات الداعمة, إنها تحقق عمليات آلية متكاملة من تنظيف البيض, الفصل الدقيق لبياض البيض وصفار البيض لتغليف المنتج النهائي الكمي. سواء لتجهيز البيض الطازج, تحضير مكونات الخبز, أو إنتاج المنتجات المعالجة بعمق مثل المايونيز ومسحوق بروتين البيض, توفر معداتنا الكاملة لتنظيف وتجهيز البيض لمصنعك بيئة صحية, فعال, وحل معالجة متعدد الطلب وقابل للتكيف. اتصل بنا الآن للحصول على خطة مخصصة!