ماكينة تعبئة سوائل جوندور

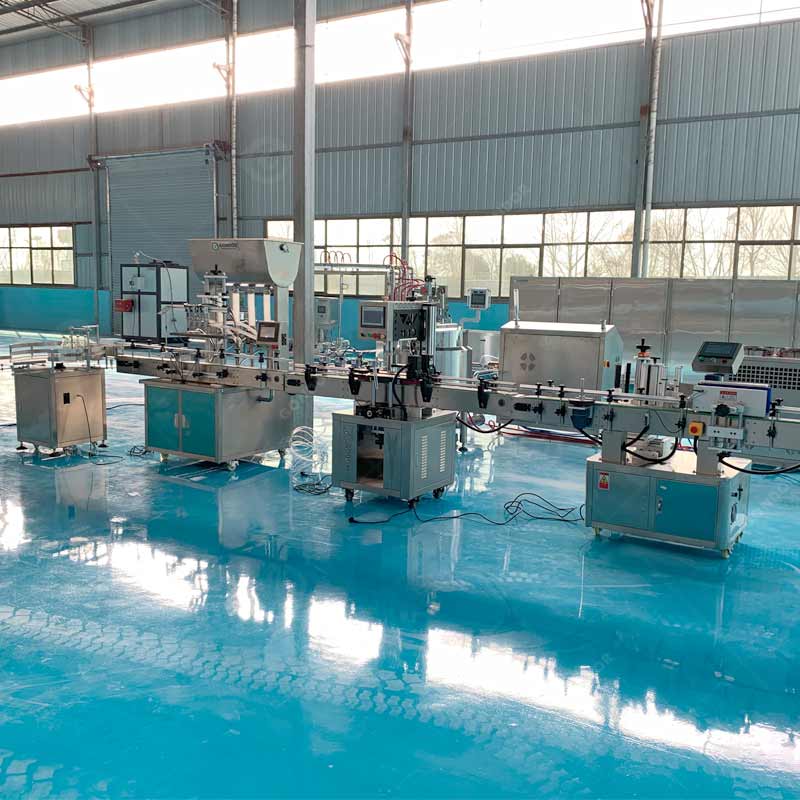

هذا خط تعبئة السوائل يدمج الفرز التلقائي للزجاجة, ملء دقيق, ختم عالي السرعة, ووضع العلامات الذكية, تشكيل نظام التعبئة والتغليف الآلي الشامل. الخط بأكمله يعتمد نظام التحكم الذكي PLC, جنبا إلى جنب مع وحدة تعبئة عالية الدقة, والتي يمكنها التحكم في خطأ ملء كل زجاجة سائل بداخلها 1%, وبالتالي تلبية احتياجات عالية السرعة, على نطاق واسع, والإنتاج الدقيق. في نفس الوقت, المعدات مصنوعة من المواد الغذائية 304 الفولاذ المقاوم للصدأ, والذي يتوافق مع المعايير الصحية الدولية, وهي ليست مستقرة في التشغيل فحسب، بل إنها أيضًا مريحة في الصيانة, مما يجعلها مناسبة جدًا لصناعة تعبئة السوائل الحديثة.

مواصفات خط إنتاج تعبئة السوائل

| منتجات | أداة فك الزجاجة | ماكينة تعبئة | آلة السد | آلة وضع العلامات |

| الجهد االكهربى | 220ضد | |||

| قوة | 120ث | 500ث | 0.8كيلووات | 1.5كيلووات |

| أَثْمَر | / | 5-60 زجاجات / دقيقة | 30-60 قطعة / دقيقة | 20-200 قطعة / دقيقة |

| وزن | 120كجم | 800كجم | 550كجم | 270كجم |

| مقاس(مم) | 1250*1250*1350 | 2000*1250*1600 | 2000*850*1800 | 1220*1250*1470 |

| قطر الزجاجة | / | / | ∅35-∅140 ملم | ∅30-∅180 مم |

| ارتفاع التسمية | / | / | / | 15-150مم |

| طول التسمية | / | / | / | 25-300مم |

| قطر غطاء الزجاجة | / | / | 20-100مم | / |

التطبيقات الصناعية لخط إنتاج تعبئة السوائل

إن خط إنتاج التعبئة هذا مناسب بشكل خاص لتعبئة المنتجات السائلة المختلفة, تغطي مجموعة واسعة من الصناعات, بما في ذلك على سبيل المثال لا الحصر:

الأداء المتميز لخط إنتاج السوائل

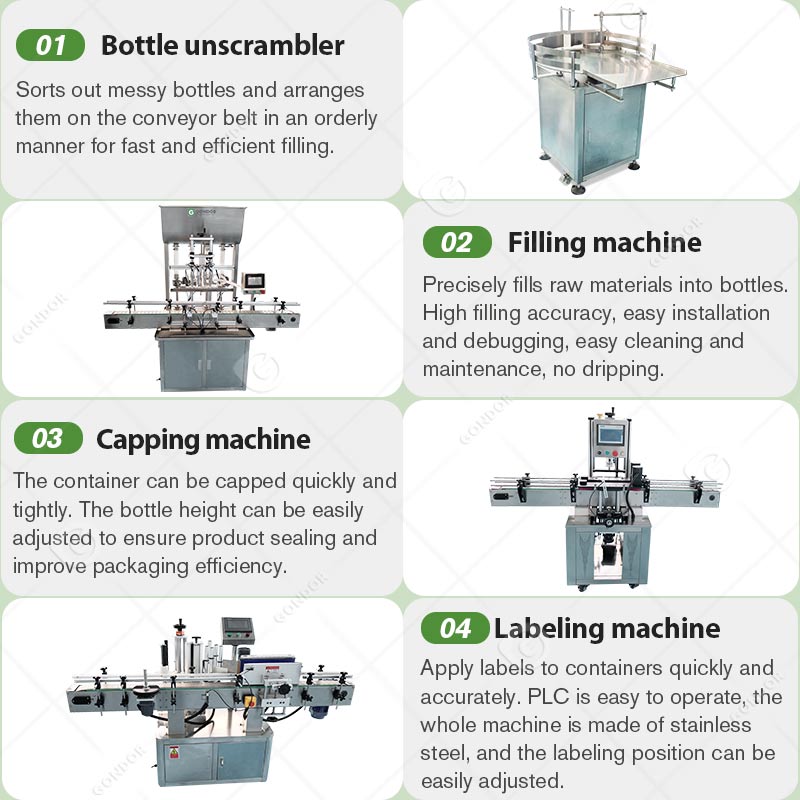

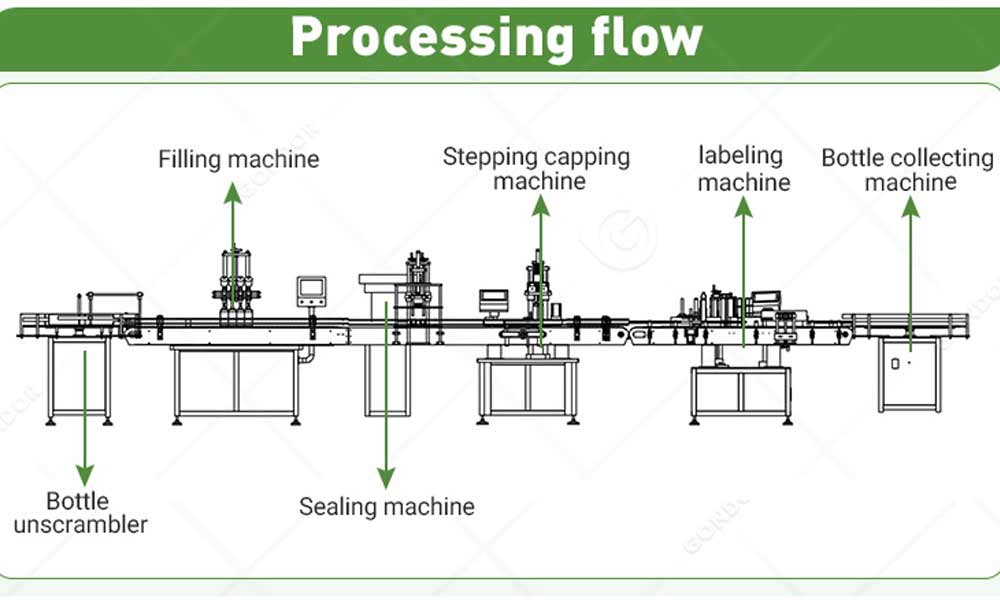

سير عمل خط تعبئة السوائل

تعتمد آلات تعبئة السوائل على التحكم في المناطق والتتبع المتزامن. تتم جدولة خط الإنتاج مركزيًا بواسطة PLC. أجهزة الاستشعار في كل محطة (كهروضوئية, مفاتيح القرب, إلخ.) اكتشف موضع الحاوية وأرسل الإشارات مرة أخرى إلى نظام التحكم, والذي يوجه بعد ذلك الآليات المقابلة (مثل ملء الرؤوس وتغطية الرؤوس) لإتمام الأفعال الدقيقة في لحظة الحركة أو السكون.

سير العمل النموذجي هو كما يلي (أخذ زجاجات المشروبات كمثال):

توريد الزجاجة الفارغة: زجاجات فارغة, بعد إزالة الباليتات أو الخروج من آلة التشكيل بالنفخ, يتم تغذيتها في خط الإنتاج في واحد, عمود متباعد بشكل متساو بواسطة الحزام الناقل.

تنظيف الزجاجة الفارغة (إذا لزم الأمر): يتم شطف الزجاجات بالهواء النقي أو الماء المعقم في محطة شطف مقلوبة مع توجيه عنق الزجاجة لأسفل.

المحاذاة والتعبئة: يقوم الحزام الناقل بتسليم الزجاجات إلى الطاولة الدوارة أو محطة التعبئة الخطية لآلة التعبئة, حيث يتم وضع عنق الزجاجة بدقة أسفل صمام التعبئة.

الختم الفوري: يتم إرسال الزجاجات المملوءة على الفور إلى وحدة الختم, حيث يمسك رأس الغطاء الغطاء ويشده, أو تضغط آلة السد على غطاء التاج.

الختم الثانوي ووضع العلامات: قد يشمل ذلك ختم رقائق الألومنيوم, ختم الفيلم يتقلص الحرارة, إلخ. يدخل المنتج بعد ذلك إلى آلة وضع العلامات من أجل التثبيت الدقيق للملصق الرئيسي.

التفتيش ووضع العلامات عبر الإنترنت: يقوم جهاز تدقيق الوزن بإزالة المنتجات ذات حجم التعبئة غير الكافي; يقوم نظام فحص الرؤية بفحص مستوى السائل, ختم, ونوعية العلامات; تقوم الطابعة النافثة للحبر بطباعة تاريخ الإنتاج ورقم الدُفعة على الزجاجة أو الملصق.

إخراج المنتج النهائي: يتم جمع المنتجات المؤهلة بواسطة حزام ناقل وتعبئتها تلقائيًا في علب كرتون أو صناديق بواسطة آلة تعبئة العلب. أخيراً, قد يتم تكديسها في أكوام على منصات نقالة بواسطة روبوت منصات نقالة, في انتظار التخزين.

مطابقة توصية المعدات

لبناء أكثر كفاءة, ورشة التغليف الأوتوماتيكية بالكامل, يمكنك أيضًا التفكير في استخدام المعدات التالية:

- سدادة الكرتون

- طابعة نافثة للحبر

- آلة نفق الانكماش الحراري

- نظام الناقل