آلة طحن القمح الصناعية: حل شامل لمعالجة الحبوب

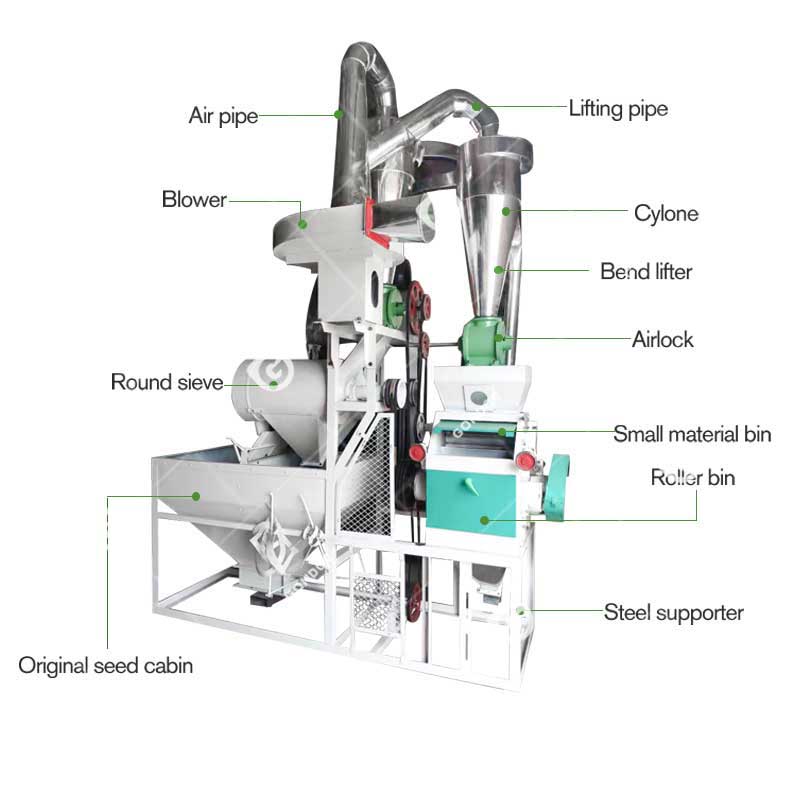

ال آلة طحن دقيق الذرة القمح الصناعية هي آلة معالجة الحبوب متعددة الاستخدامات ومناسبة لمطاحن الدقيق المنزلية الصغيرة التي تطحن القمح أو الذرة, ولمصانع المواد الغذائية التي تتطلب معالجة دقيقة للحبوب المختلفة, بما في ذلك حبوب الكاكاو, فول الصويا, الشوفان, وغيرها من المواد ذات الصلابة المختلفة. تتميز بتصميم وحدات, تشتمل مكوناته الأساسية على نظام تغذية, نظام الطحن, نظام الفحص, نظام النقل, ونظام التحكم الذكي. تعمل هذه الأنظمة بشكل متضافر لضمان الكفاءة التشغيلية الشاملة والاستقرار. والأهم من ذلك, هيكلها المغلق يمنع تسرب الغبار بشكل فعال, ليس فقط تلبية معايير النظافة الصارمة ولكن أيضًا تقليل استهلاك الطاقة بشكل كبير مع تبسيط إجراءات الصيانة الروتينية.

بفضل قدرتها على الطحن الدقيق لإنتاج دقيق فائق النعومة يتراوح من 40 ل 120 شبكة, يتم اعتماد آلة طحن القمح على نطاق واسع في مطاحن الدقيق, مصانع تجهيز الأغذية, موردي مكونات الخبز, ومصنعي المواد الغذائية المتخصصة. سواء كانت متاجر المعكرونة الحرفية التي تتبع نسيج الدقيق التقليدي المطحون على الحجر أو مصانع الأغذية واسعة النطاق التي تتطلب إنتاجًا ضخمًا موحدًا, يمكن تحقيق جودة المنتج المثالية عن طريق ضبط معلمات الطحن. تمكن هذه القدرة على التكيف المعدات من تلبية الاحتياجات المتنوعة - بدءًا من معالجة الحبوب الأساسية وحتى إنتاج الأغذية ذات القيمة المضافة العالية - مما يوفر تحكمًا دقيقًا بدءًا من المواد الخام وحتى المنتجات النهائية.

| نموذج | الإخراج (كجم/ساعة) | وزن (كجم) | البعد(مم) | قوة(كيلووات) |

| 6F2235 | 200~350 | 800 | 2200*900*3150 | 7.5+3 |

| 6F2240 | 300~450 | 900 | 2250*1000*3150 | 11+3 |

| 6F2250 | 400~550 | 1000 | 2350*1000*3150 | 15+4 |

مجالات الطلب على آلة طحن الدقيق

شركات إنتاج الدقيق

هم جانب الطلب الرئيسي, إنتاج أنواع مختلفة من الدقيق لصنع الخبز, الشعرية, الكعك والأطعمة الأخرى.

مصانع تجهيز الأغذية

مثل مصانع تجهيز المعكرونة, مصانع إنتاج أغلفة الزلابية, إلخ., تتطلب دقيقًا بجودة محددة لمعالجة المنتجات.

شركات الخبز

هناك طلب كبير على أنواع مختلفة من الدقيق, والتي تستخدم في صنع الأطعمة المخبوزة ذات الأذواق والخصائص المختلفة.

صناعة الأعلاف

معالجة الحبوب والمواد الخام الأخرى إلى مسحوق علف مناسب للحيوانات المختلفة. تحتاج بعض الأعلاف إلى سحقها جيدًا لتسهيل عملية الهضم والامتصاص لدى الحيوان.

مصنع الخمور

تحتاج بعض المواد الخام مثل الذرة الرفيعة والقمح إلى سحقها وتخميرها قبل عمليات التخمير.

الصناعة الكيميائية

استخدام مطاحن الدقيق لسحق مواد خام محددة لإنتاج المواد الخام أو المواد المضافة للمنتجات الكيماوية.

صناعة الأدوية

سحق بعض المواد الطبية لتلبية متطلبات حجم جزيئات المادة الخام لأشكال الجرعات المختلفة في عملية إنتاج الأدوية.

مجال البحث العلمي

مؤسسات البحوث الزراعية: تستخدم لدراسة تكوين وبنية محاصيل الحبوب, الأمر الذي يتطلب طحن الحبوب إلى مسحوق لتحليلها واختبارها.

وحدات البحوث الغذائية

في طور تطوير صيغ غذائية جديدة, من الضروري طحن المواد الخام للاختبار.

بعض قواعد المعالجة الشاملة واسعة النطاق

تجهيز مجموعة متنوعة من المحاصيل, مطحنة الدقيق هي واحدة من معدات المعالجة.

المزايا الممتازة لآلة طحن القمح جوندور

-

قدرة إنتاجية عالية

يمكنها معالجة كمية كبيرة من المواد الخام للحبوب لكل وحدة زمنية لتلبية احتياجات الإنتاج على نطاق واسع.

-

التشغيل المستمر

لديها القدرة على العمل بشكل مستقر لفترة طويلة, دون الاغلاق المتكرر والراحة, مما يحسن بشكل كبير كفاءة الإنتاج.

-

درجة عالية من الأتمتة

تقليل التدخل اليدوي, إكمال سلسلة من العمليات تلقائيًا مثل التغذية, طحن, الفحص والتفريغ, توفير الوقت والقوى العاملة.

-

طحن دقيق

يمكن تعديل دقة الطحن حسب الاحتياجات, ويمكن ضمان اتساق كل دفعة من المنتجات.

-

سهلة التركيب

يتم توصيل جميع الواجهات بواسطة الشفاه, مع بصمة صغيرة وعملية بسيطة.

-

هيكل معقول

عملية مستقرة, أداء موثوق, ضوضاء منخفضة, لا غبار, آمنة وصحية, موفرة للطاقة وصديقة للبيئة.

الميزات التقنية الأساسية

توصيات الصيانة والتحسين

قم بتنظيف المواد المتبقية من أقراص الطحن بعد كل نوبة. فحص ارتداء شبكة الشاشة أسبوعيا.

تتيح وحدة إنترنت الأشياء الاختيارية المراقبة في الوقت الفعلي لبيانات أداء المعدات وتشخيص الأخطاء عن بُعد.

قم بتنظيف المواد المتبقية من أقراص الطحن بعد كل نوبة. فحص ارتداء شبكة الشاشة أسبوعيا.

آلة طحن دقيق الذرة والقمح جوندور – افتتاح عصر جديد من الكفاءة

آلة طحن دقيق الذرة والقمح هي خيارك الأفضل لتحسين كفاءة إنتاج الدقيق! تتمتع بقدرة طحن قوية ويمكنها معالجة كميات كبيرة من الحبوب بسرعة, مما يوفر لك الوقت والتكلفة. فضلاً عن ذلك, المنتجات النهائية التي تنتجها هذه المعدات لها خصائص الدقيق الناعم, نسبة عالية من الغلوتين, قليل من الشوائب, وقيمة غذائية عالية. اختيار جوندور يعني اختيار الكفاءة, الجودة والثقة. اطلب الآن, دعونا خلق مستقبل أفضل معا!