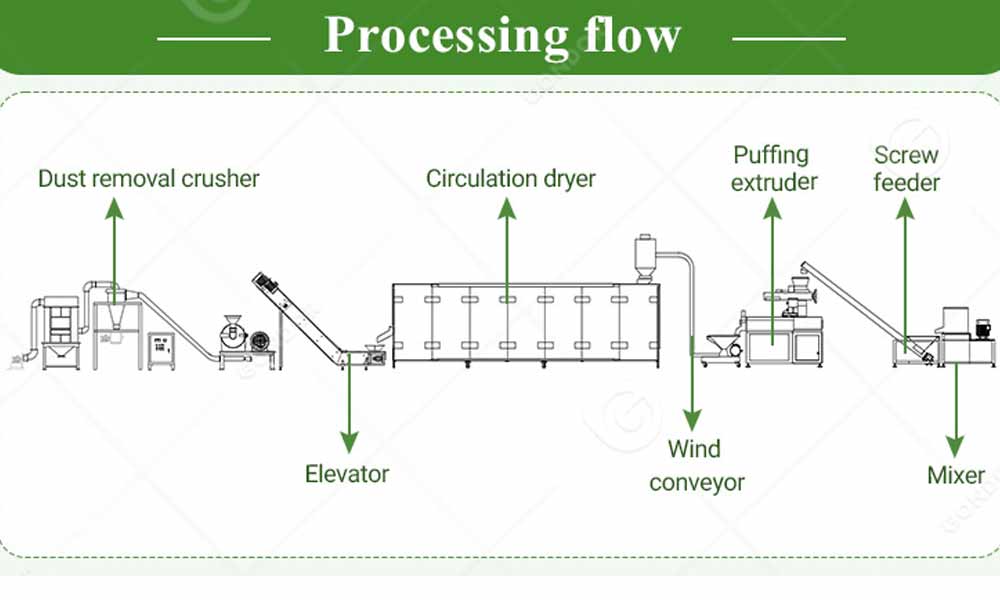

Для удовлетворения спроса на качество и диверсификацию на рынке детского питания., мы запустили эффективную, разумный, и стабильный линия по производству детского питания. Автоматическая линия производства специально разработана для рисовой пасты., рисовая мука, рисовое молоко и другие продукты, изготовленные из пищевой нержавеющей стали., который соответствует международным стандартам безопасности. Весь процесс автоматизирован, обеспечение отсутствия потерь питательных веществ и более стабильное качество, и поддержка настройки различных формул, таких как оригинальный вкус, овощи, фрукты, и мясо для удовлетворения пищевых потребностей детей грудного возраста на разных этапах.

|

Имя |

Напряжение | Власть | Урожай | Материал | Размер |

| Порошковый смеситель | 380В | 7.5кВт | 50кг/раз | 304ИХ | 1300*800*1500мм |

|

Шнековый питатель |

1.1кВт | / | 304ИХ | 3000*600*2100мм | |

| Пыхающий экструдер | 46.62кВт | 200-300кг/ч | 201ИХ | 2510*780*1925мм | |

|

Ветер конвейер |

2.2кВт | / | 304ИХ | 2000*600*2300мм | |

| Циркуляционная сушилка | 45кВт | 200-300кг/ч | 304ИХ | 5300*1250*1750мм | |

| Лифт (необязательный) | 1.1кВт | / | 304ИХ | 2000*600*3450мм | |

| Дробилка для удаления пыли | 18.75кВт | 200-300кг/ч | 304ИХ | 6500*1100*3000мм |

Рыночная сфера применения оборудования для переработки детского питания

Производственная линия имеет широкий спектр применения., может удовлетворить производственные потребности многих отраслей промышленности в питательных продуктах питания, и очень гибкий и практичный.

Кроме того, за счет простой регулировки, оборудование может расширить производство разнообразных продуктов, таких как мультизерновая мука., здоровое зерно, и паста из черного кунжута для удовлетворения большего спроса рынка.

Отличные эксплуатационные преимущества оборудования для детского питания

С помощью точного мукомешалки, разнообразное сырье, такое как зерно, фрукты и овощи, белок и т. д. равномерно смешиваются для достижения точного соотношения питательных веществ и удовлетворения различных потребностей в питании..

Экструдерная обработка при высокой температуре и высоком давлении обеспечивает полное созревание сырья., и готовая продукция прекрасная и гладкая, что полезно для пищеварения и всасывания младенцев.

Изменяя форму и корректируя формулу сырья., Формованный рис и гранулированное рисовое молоко различных размеров и форм могут быть произведены для удовлетворения разнообразных потребностей рынка..

Все детали, контактирующие с пищевыми продуктами, изготовлены из 304 Нержавеющая сталь, который устойчив к коррозии и легко чистится, обеспечение гигиены и безопасности продукции.

Из шнекового питателя, ветровой конвейер, циркуляционный осушитель воздуха и пылесборник, вся линия использует интеллектуальную систему управления, что значительно повышает эффективность производства и экономит затраты на рабочую силу.

Модульная конструкция производственной линии, крупномасштабная или мелкосерийная конфигурация может быть выбрана в соответствии с фактическим местоположением клиента и потребностями в мощности., который совместим с различными производственными планами.

Научное питание, Интеллектуальное производство

Эта линия по производству детского питания может использоваться не только для массового производства детского питания., но также широко использоваться во многих областях, таких как здоровое питание и зерновые продукты.. Если вы заинтересованы в линия по производству протеиновых батончиков или линия по производству искусственного риса, пожалуйста, свяжитесь с нами. Мы можем предоставить вам универсальные решения и индивидуальные услуги..