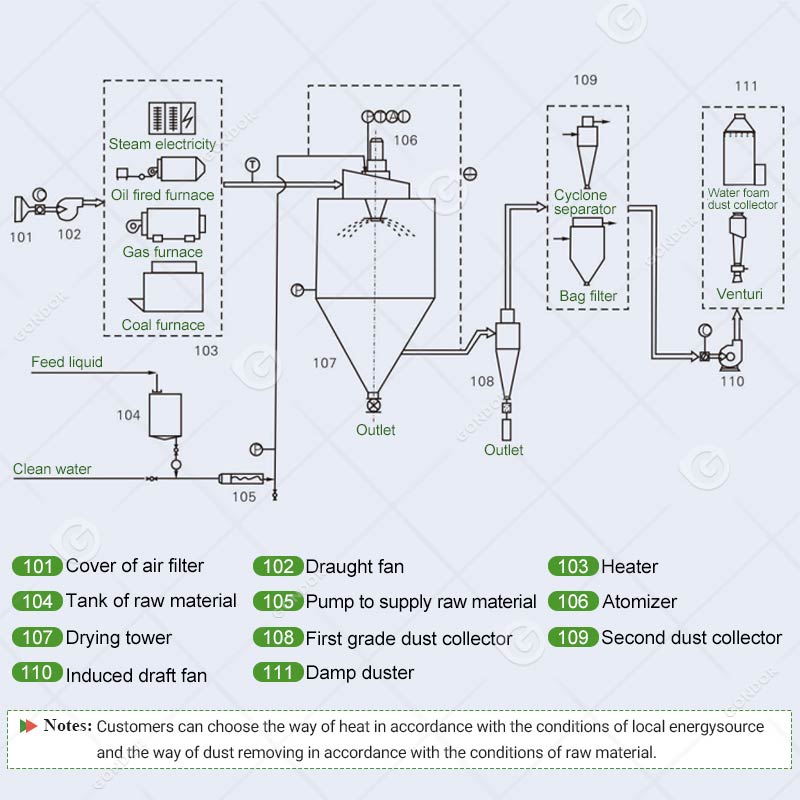

А центробежная распылительная сушилка эффективное сушильное оборудование, специально разработанное для быстрого преобразования жидкости, эмульсия, или суспензионные материалы в порошкообразные или гранулированные продукты. Оборудование распыляет исходную жидкость на мелкие капли с помощью высокоскоростного вращающегося центробежного распылителя, а затем полностью контактирует с высокотемпературным сушильным газом для мгновенного испарения воды и завершения быстрого процесса сушки.. Готовый порошок имеет хорошую текучесть и однородный размер частиц., Это идеальное решение для сушки пищевых продуктов., химическая промышленность, медицина и другие отрасли.

| Модель | ГД-5 | ГД-25 | ГД-50 | ГД-100 | ГД-150 | ГД-200-2000 |

| Температура на входе’C | 140-350 автоматически управляемый | |||||

| Температура на выходе’C | ~80-90 | |||||

| Макс. производительность испарения воды кг/ч | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| Режим передачи сопла центробежного распыления | Передача сжатого воздуха | Механическая трансмиссия | ||||

| Скорость вращения(об/мин) | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| Диаметр распылительного диска(мм) | 50 | 100 | 120 | 140 | 150 | 180-340 |

| Теплоснабжение | Электричество | Электричество

+пар |

Электричество+пар,

мазут и газ |

Решается самими пользователями | ||

| Максимальная мощность электрического нагрева (кВт) | 9 | 36 | 63 | 81 | 99 | / |

| Габаритные размеры(м) | 1.8×0.93 х2,2 | 3×2.7×4.26 | 3.7×3.2×5.1 | 4.6×4.2×6 | 5.5×4.5×7 | Зависит от конкретных условий |

| Сбор сухого порошка% | ≥95 | |||||

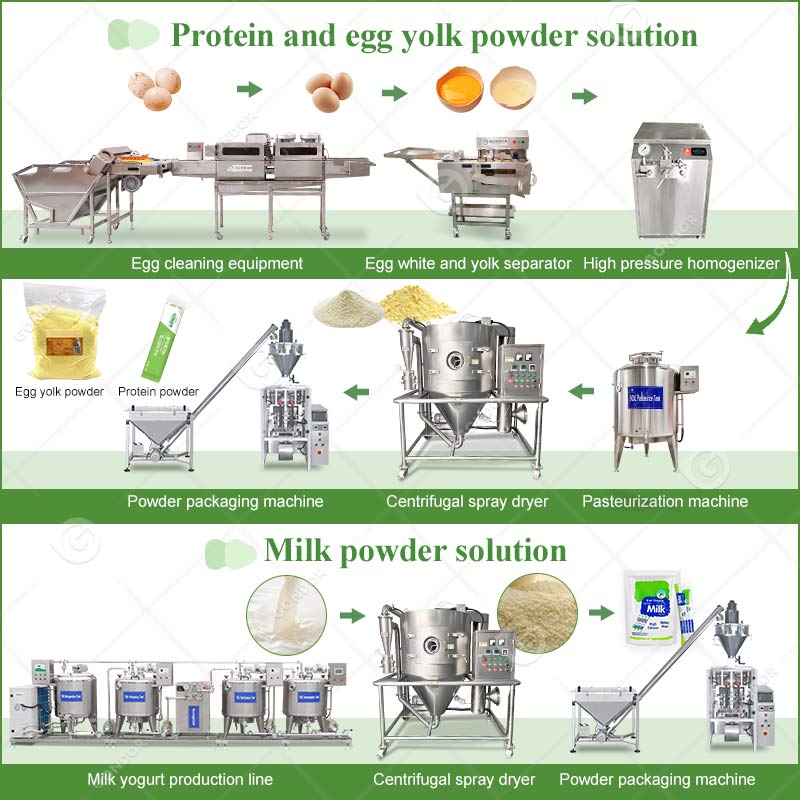

Рынок использования распылительной сушилки

Данное оборудование широко используется в следующих отраслях::

Ключевые особенности & Преимущества распылительной сушилки

Рекомендуемый инструмент для сушки

Центробежная распылительная сушилка, с его основными преимуществами высокой эффективности, точность, и защита окружающей среды, становится ключевым оборудованием глобальных решений для сушки порошков. Неважно пищевые заводы, фармацевтические предприятия, или линии химического производства, они могут извлечь из этого пользу и реализовать совершенный скачок “жидкость в порошок”. Если вас интересует другое сопутствующее оборудование, такой как вакуумная сублимационная сушилка или небольшая сублимационная сушилка, пожалуйста, продолжайте просматривать нашу страницу продукта или свяжитесь с профессиональной командой продаж для получения дополнительной поддержки.