Gondor Cocoa Bean Colloid Mill Machine Introduction

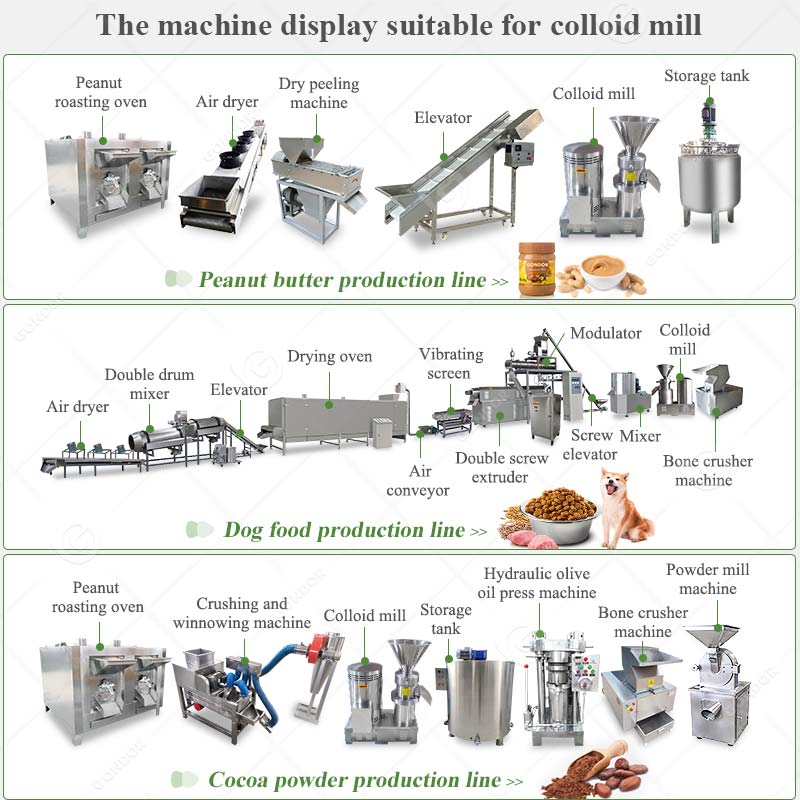

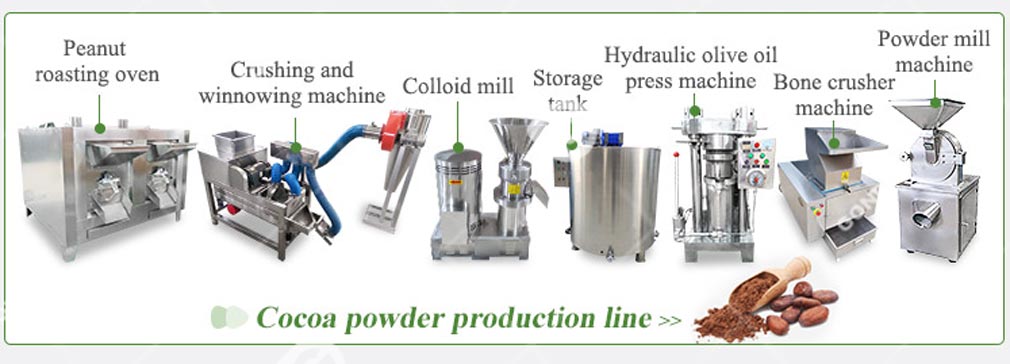

The cocoa bean colloid mill machine is specially designed for ultra-fine wet grinding of cocoa beans, transforming roasted cocoa nibs into smooth cocoa liquor with excellent fineness, единообразие, and flavor retention. As an automatic cocoa bean colloid mill machine, it integrates crushing, emulsifying, homogenizing, and mixing into one continuous process, making it a key unit in cocoa and chocolate processing lines.

This cocoa colloid mill utilizes high-speed rotor–stator shear to efficiently reduce cocoa bean particle size, allowing cocoa butter to be fully released and evenly distributed throughout the cocoa mass. The result is a smooth, stable cocoa paste suitable for further processing into chocolate products, cocoa butter extraction, производство какао-порошка, or chocolate spreads.

Manufactured from sanitary food-grade stainless steel, this coco bean mill ensures excellent hygiene, коррозионная стойкость, и легкая очистка. Its compact structure and simple operation help reduce labor requirements while maintaining high production efficiency. When used as a cocoa butter machine, it supports consistent grinding and emulsification of cocoa materials with high oil content.

Gondor Cocoa Bean Colloid Mill Machine Models

| Модель | Напряжение | Размер(мм) | Масса | Емкость |

| ГД-70 | 3кВт(Single-Phase, 220в) | 650x320x650 | 70кг | 60-80кг/ч |

| ГД-80 | 5.5кВт(Three-Phase, 380в) | 800х350х800 | 170кг | 100-150кг/ч |

| ГД-130 | 11кВт(Three-Phase, 380в) | 1000х350x1000 | 270кг | 200-300кг/ч |

| ГД-180 | 30кВт(Three-Phase, 380в) | 1200х450х1200 | 470кг | 500-800кг/ч |

| ГД-200 | 37кВт(Three-Phase, 380в) | 1250х500Х1200 | 500кг | 800-1000кг/ч |

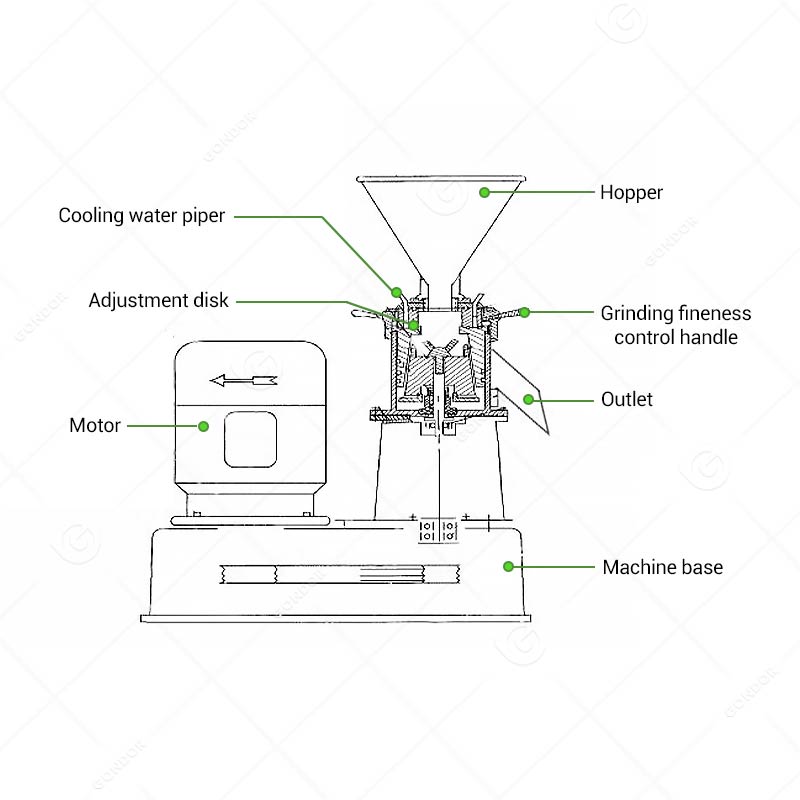

Working Principle of Cocoa Bean Colloid Mill Machine

The cocoa bean colloid mill works through a combination of a high-speed rotating rotor and a fixed stator. The motor drives the rotor via a belt system, creating a strong grinding action between the rotating and stationary components.

When cocoa materials enter the grinding chamber, they are pushed forward by their own weight or by external pressure from a pump. As the material passes through the adjustable gap between the rotor and stator, it is subjected to multiple forces at the same time, including strong shear, трение, squeezing, and high-speed vortex action.

Application Raw Materials for Gondor Cocoa Bean Colloid Mill Machine

- Какао-бобы: Wet grinding into fine cocoa mass with uniform particle size.

- Какао-бобы: Efficient size reduction and emulsification for smooth cocoa paste.

- Solid Chocolate Blocks/Chocolate Chips: Directly processed into refined chocolate paste.

- Chocolate Compound Materials: Stable grinding of cocoa butter–based chocolate mixtures

- Орехи(Peanut/Almond/Hazelnut/Cashew): Suitable for producing nut paste and nut butter.

- Кофе в зернах: Processed after soaking or mixing with water for coffee slurry or paste.

Gondor Cocoa Bean Colloid Mill Machine Application Industries

- Шоколад & Cocoa Processing Plants: Used for ultra-fine grinding of cocoa beans, шоколадные блоки, and cocoa-based mixtures.

- Магазины десертов & Пекарни: Ideal for producing fresh chocolate sauce, cocoa paste, nut–chocolate fillings, and dessert toppings in-house.

- Кондитерское производство: Suitable for chocolate spreads, пломбы, and compound chocolate production.

- Обработка пищевых ингредиентов: Supports stable grinding and homogenizing of cocoa-based semi-fluid materials.

- Кофе & Производство напитков: Applicable for wet grinding of coffee-based pastes and cocoa-flavored beverage bases.

Gondor Cocoa Bean Colloid Mill Machine Features

- Convenient and Efficient Operation: Designed for fast processing with stable performance, improving overall production efficiency.

- Simple and User-Friendly Control: Easy to operate with minimal training required, suitable for continuous operation.

- Food-Grade Stainless Steel Structure: Made of sanitary food-grade stainless steel to ensure hygiene, безопасность, и легкая очистка.

- Высокая эффективность производства: Optimized grinding structure delivers consistent output and reliable long-term performance.

Почему стоит выбрать Gondor Machinery?

- Reliable After-Sales Service: Long-term technical support with no time limit, plus operation videos and instructions provided with shipment.

- Custom Branding Available: Your logo/company name can be added on the machine or packaging (печать, embossing, sticker, и т. д.).

- Clear Warranty & Поставка запасных частей: 1-year warranty from arrival at the destination port, and affordable spare parts available after warranty.

- On-Site Installation Option: Experienced engineers can provide installation service at your plant (extra service fee applies).

- Export-Ready Packaging: Standard export plywood case to protect the machine during international shipping.

- Quick Quotation Response: Pricing feedback within 24 hours for efficient procurement.

- Широкая совместимость материалов: Machines can handle different raw materials to meet diverse production needs.