Точное приготовление для превосходных результатов

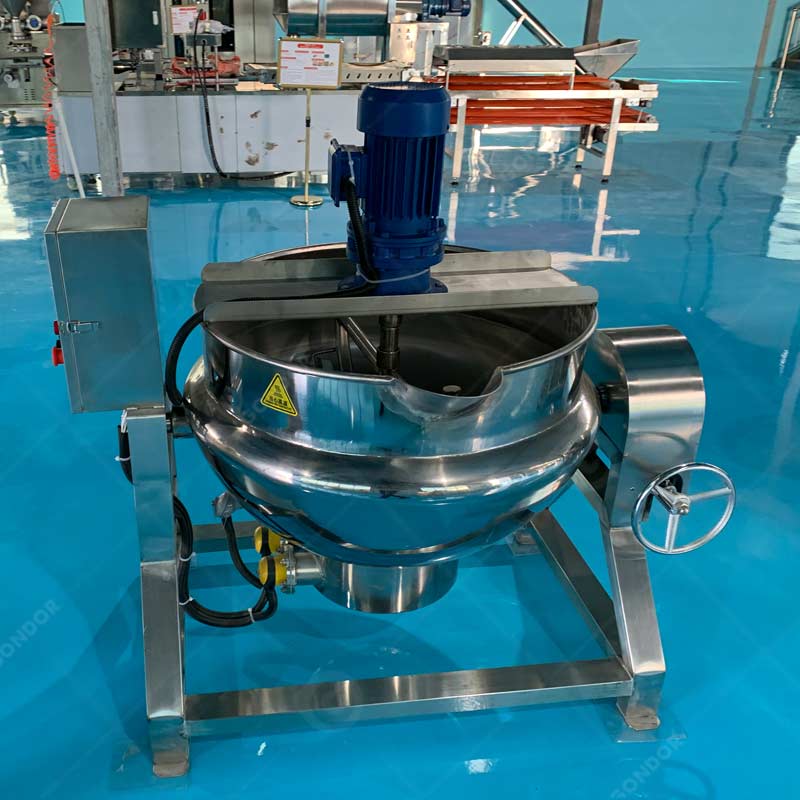

Гондор паровой чайник с двойной рубашкой выступает в качестве важного инструмента для современного производства продуктов питания, специально разработан для варки конфет исключительной консистенции. Изготовлен из высококачественных, безопасных для пищевых продуктов материалов., он обеспечивает превосходную коррозионную стойкость и оптимальное распределение тепла., обеспечение как чистоты продукта, так и операционной эффективности. Эта прочная основа делает его идеальным для сложных процессов кондитерского производства..

Помимо прочной конструкции, чайник оснащен усовершенствованным механизмом перемешивания, точная система отопления, и интуитивно понятное управление для создания идеально управляемой среды приготовления пищи. Эта синергия позволяет производителям надежно производить все: от нежных сахарных сиропов до густых пикантных основ., гарантия однородности вкуса и текстуры от партии к партии. Подходит для кондитерских фабрик., пищевые растения, и просторные кухни, он обеспечивает контроль, необходимый для получения высококачественной продукции.

|

Модель |

Емкость | Размер | Диаметр горловины горшка | Мощность электрического нагрева | Мощность газового отопления |

| ГД-BYJKM-50 | 50л | 1300*750*900мм | 600мм | 12кВт |

0.75кВт |

|

ГД-BYJKM-100 |

100л | 1400*850*900мм | 700мм | 18кВт | 1.1кВт |

| ГД-BYJKM-200 | 200л | 1500*950*900мм | 800мм | 24кВт |

1.5кВт |

|

ГД-BYJKM-300 |

300л | 1600*1050*900мм | 900мм | 24кВт | 1.5кВт |

| ГД-BYJKM-400 | 400л | 1700*1150*900мм | 1000мм | 36кВт |

1.5кВт |

|

ГД-BYJKM-500 |

500л | 1750*1250*950мм | 1100мм | 36кВт | 2.2кВт |

| ГД-BYJKM-600 | 600л | 1850*1350*950мм | 1200мм | 48кВт | 2.2кВт |

Основные сферы услуг паровых котлов с двойной рубашкой

Используется для приготовления различных блюд, например, тушение, кипящий суп, кипящие соусы, и т. д.. Из него также можно приготовить особые деликатесы., например, основа для горячего горшка, рассол, и т. д., обеспечить уникальные вкусы для ресторанов.

Переработка различных консервов, приправы, джемы, и т. д.. Подходит для крупносерийного производства., повышение эффективности производства и снижение производственных затрат.

Варить сиропы, шоколадные конфеты, и т. д.. делать различные специальные конфеты и выпечку, добавить уникальные вкусы, улучшить качество и сортность продукции, и удовлетворить различные потребности потребителей.

В фармацевтическом процессе, его можно использовать для кипячения мазей китайской медицины, отвары, и т. д., которые могут повысить эффективность лекарств и обеспечить качество и безопасность лекарств..

Оборудование можно использовать для кипячения пастообразного сырья в повседневных химических продуктах, таких как зубная паста, для достижения соответствующей температуры и концентрации, чтобы обеспечить качество и стабильность продуктов..

Например, медовая паста, желатиновая паста из ослиной шкуры, и т. д., Температуру и время нагрева можно регулировать в соответствии с потребностями различных медицинских изделий для удовлетворения разнообразных потребностей рынка..

Уникальные характеристики чайника с паровой рубашкой Gondor

Комплексное решение для интеграции линии по производству конфет

Чтобы создать всеобъемлющую линия по производству мармеладных конфет, это оборудование легко интегрируется со следующими компонентами:

- Сахар плавильный котел: Предварительно растворяет сырье, такое как сахарный песок.. Непосредственно подключается к кипящему котлу через трубопровод для автоматической подачи материала..

- Система дозирования ингредиентов: Точно добавляет красители, ароматизаторы, и другие добавки для обеспечения единообразия рецептов..

- Машина для откладывания конфет: Непосредственно получает расплавленный сахарный сироп для точного, дозированное формование.

- Охлаждающий туннель: Подключается ниже по потоку для быстрого охлаждения и затвердевания формованных конфет..

- Упаковочная машина: Интерфейсы с охлаждающим туннелем для автоматизированной упаковки конфет..

- Интеллектуальная система управления: Централизованная панель управления обеспечивает единую настройку всех параметров линии., достижение полностью автоматизированного производства по плавлению сахара, кипение, формование, к упаковке.

Высококачественный паровой чайник с двойной рубашкой от Gondor – Первый выбор для производства сладостей

Наш паровой котел с двойной рубашкой превосходного качества.. Точный контроль температуры и равномерный нагрев обеспечивают идеальное кипячение сахара.. Пищевой материал, безопасный, гигиеничен и легко чистится. Подходит для конфет., кондитерская и другие отрасли промышленности. Эффективное кипячение приносит вам богатство. Выберите Гондор ,Паровой чайник с двойной рубашкой, чтобы начать свой сладкий карьерный путь.