Двойная гарантия качества и эффективности пищевого масла

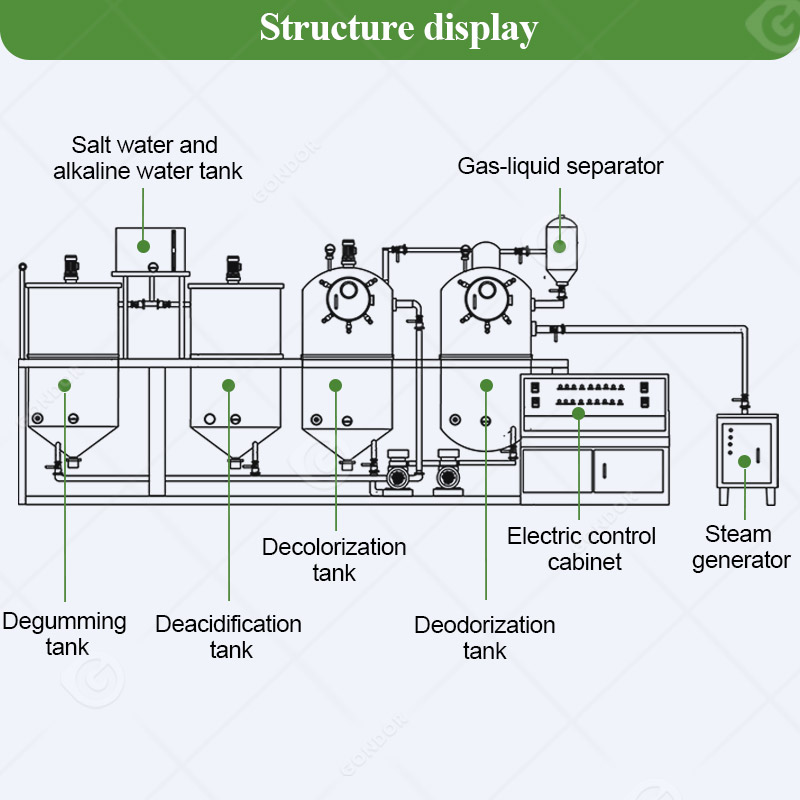

Гондора машина для переработки пищевого масла предназначен для эффективной обработки и подходит для более чем 20 виды масличных культур, включая оливки, арахис, кунжут, соевые бобы, и многое другое. Оборудование изготовлено из пищевой нержавеющей стали., который является одновременно устойчивым к коррозии и термостойким, соответствие национальным стандартам пищевого оборудования. Он объединяет несколько функций, например, дефосфоризация, деалкализация, обезвоживание, и обесцвечивание, эффективно удаляет примеси и вредные вещества как физическими, так и химическими методами очистки.. Более того, он подходит для различных применений, включая маслобойни и предприятия пищевой промышленности. С низкими инвестиционными затратами и высокой доходностью, это оборудование является идеальным выбором для клиентов по всему миру, желающих перерабатывать сырую нефть..

|

Модель |

Мощность обработки(кг/партия) | Мощность двигателя(кВт) | Напряжение(в) | Внешние размеры(мм) | Масса(кг) |

| ГД-ОРФМ500 | 150 | 4.5 | 220/380 | 1740*680*1510 |

180 |

|

ГД-ОРФМ750 |

300-600 | 9.5 | 220/380 | 2340*930*1700 | 300 |

| GD-ORFM750B | 450-900 | 15 | 380 | 3820*930*1700 |

550 |

|

ГД-ОРФМ700 |

500-1000 | 52 | 380 | 4500*1080*2320 | 1200 |

|

GD-ORFM700B |

500-1000 | 8.2 | 380 | 3500*880*1800 | 1000 |

Области спроса на нефтеперерабатывающее оборудование Гондора

Нефтеперерабатывающее оборудование Gondor широко используется при переработке различных масличных культур благодаря своей эффективной перерабатывающей способности и многофункциональной конструкции.. Будь то пищевая промышленность, ресторанный бизнес, или в химическом, фармацевтическая и другие отрасли промышленности, это оборудование может обеспечить высококачественные решения по переработке нефти.. Ниже приведены основные области спроса на это оборудование.:

Уникальные механические характеристики машины для переработки растительного масла Гондора

Нефтеперерабатывающее оборудование Гондора продемонстрировало свои уникальные преимущества в процессе переработки нефти благодаря передовому техническому дизайну и эффективной работе.. Оборудование подходит не только для переработки различных масличных культур., но и обеспечивает эффективность, стабильность и качество продукта процесса нефтепереработки благодаря ряду инновационных механических характеристик.

Принятие пищевой нержавеющей стали, он устойчив к коррозии и высоким температурам, соответствует национальным стандартам пищевого оборудования, и гарантирует, что масло не загрязняет окружающую среду.

Интегрированная дефосфорация, деалкализация, обезвоживание, обесцвечивание и другие многофункциональные функции, гибкая настройка, улучшить применимость оборудования, и удалить масляные примеси.

Автоматизированная электронная система управления упрощает эксплуатацию., интеллектуально контролирует процесс переработки, и уменьшает человеческие ошибки.

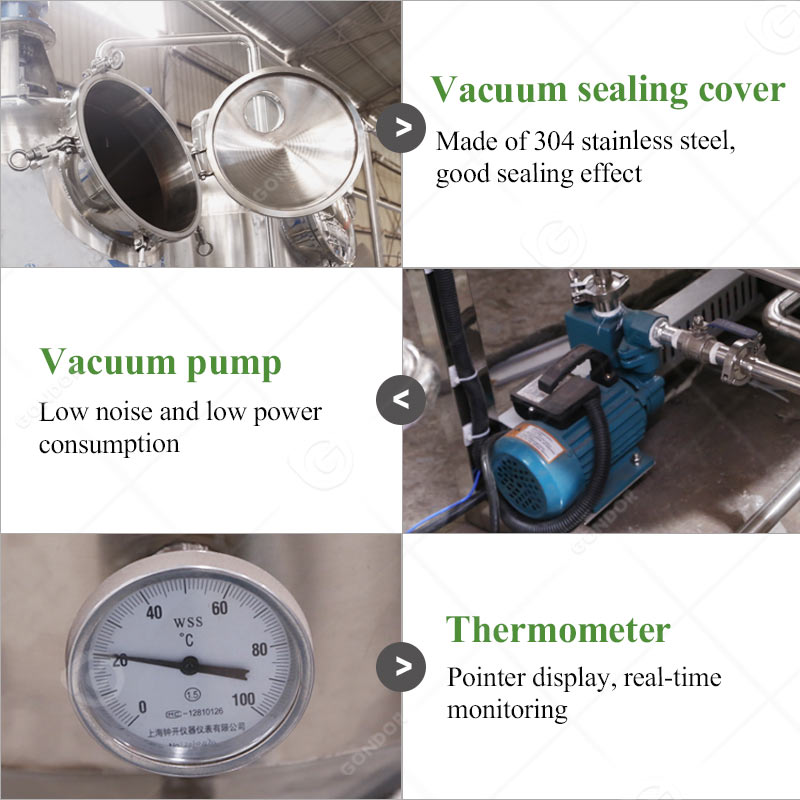

Эффективный вакуумный насос удаляет влагу и летучие примеси, обеспечивая тихую производственную среду..

304 Вакуумная крышка из нержавеющей стали предотвращает внешние загрязнения и обеспечивает чистоту нефтепродуктов.

Встроенная система циркуляции воды экономит водные ресурсы., оптимизирует использование энергии, и снижает эксплуатационные расходы.

Быстро отделяет воду и пар, повышает эффективность переработки, и снижает потребление энергии.

Точная система контроля температуры контролирует в режиме реального времени, чтобы обеспечить соответствующую температуру в каждом звене и улучшить качество масла..

Компактный дизайн экономит место, а модульная структура облегчает установку, разборка и обслуживание, повышение эффективности производства.

Машина для переработки пищевого масла Гондора улучшает качество масла и снижает затраты

Нефтеперерабатывающее оборудование Гондора имеет многофункциональную интегрированную конструкцию., оснащен интеллектуальной системой управления и изготовлен из пищевой нержавеющей стали., который подходит для очистки оливок, арахис, кунжут и соевые бобы. Оборудование интегрирует дефосфорацию, деалкализация, обезвоживание, обесцвечивание и другие процессы для обеспечения соответствия рафинированного масла национальным стандартам и значительного улучшения качества и стабильности масла.. Благодаря характеристикам низкой инвестиционной стоимости и высокой эффективности возврата, это идеальный выбор для нефтедобывающих предприятий.

Если вы планируете построить полную линию по производству масла от прессования до переработки, это оборудование может сочетаться с гидравлическая машина для производства масла холодного отжима, который подходит для высококачественной технологии холодного прессования, которая уделяет внимание сохранению аромата масла. Он также может быть связан с винтовой пресс для извлечения масла реализовать комплексное производство непрерывного и эффективного прессования и рафинирования. Выбрав Гондор, можно получить эффективную и стабильную систему переработки и устойчивые экономические выгоды.. Добро пожаловать, чтобы заполнить поле запроса ниже для получения подробной информации и профессиональной поддержки решений.!