Линия по производству фрикаделек Гондора Введение

Автоматический машина для изготовления фрикаделек это современное решение, призванное упростить и улучшить производство фрикаделек.. Интеграция измельчения, резка чаши, формирование, по желанию жарка или бланширование, охлаждение, и быстрая заморозка, он обеспечивает высокую эффективность и стабильное качество на каждом этапе. Изготовлен из пищевой нержавеющей стали и усовершенствованной автоматизации., автоматическая линия по производству фрикаделек обеспечивает стабильную производительность, превосходная текстура, и безопасная гигиеническая обработка, что делает его идеальным выбором для профессионального производства фрикаделек..

>

Модели линий по производству фрикаделек Гондора

Наша линия по производству фрикаделек состоит из полного комплекта оборудования., ниже приведены некоторые модели оборудования.

| Продукт |

Машина для измельчения замороженного мяса |

Машина для резки чаши |

Машина для формирования фрикаделек |

Машина непрерывного жарения |

Бланшировальная машина |

Охлаждение & Сушильная машина |

Туннельная морозильная машина |

| Напряжение |

380в |

220в |

380в |

| Власть |

5.5кВт |

4.1кВт |

1.1кВт |

48кВт |

40кВт |

3.5кВт |

20кВт |

| Выход |

500кг/ч |

15к/можно |

280шт/мин |

/ |

/ |

/ |

100кг/ч |

Применение машины для изготовления фрикаделек Гондора

Предприятия, использующие производственные линии по переработке фрикаделек Гондора

Автоматическая машина для изготовления фрикаделек Gondor обслуживает центральные кухни, пищевые заводы, поставщики замороженных продуктов, сеть ресторанов, и предприятия общественного питания, наряду с крупными супермаркетами и распределительными центрами.

Центральные КухниПищевые предприятияПоставщики замороженных продуктовСеть ресторанных предприятийКрупные супермаркетыРаспределительные центры

Адаптируется к массовым предпроизводственным потребностям центральных кухонь., с полностью автоматизированным процессом для эффективного производства стандартизированных фрикаделек, содействие быстрой доставке продуктов питания и обеспечению стабильного качества.

Удовлетворяет крупномасштабным производственным потребностям предприятий пищевой промышленности., с полностью автоматизированным контролем на протяжении всего процесса, обеспечение однородного вкуса и характеристик фрикаделек, повышение производственных мощностей и урожайности.

Адаптируется к требованиям обработки замороженных продуктов., производственная линия подключается к оборудованию для заморозки продуктов в конце для быстрой фиксации свежести, обеспечение стабильного качества котлет после заморозки.

Предоставляет стандартизированные решения для фрикаделек для сетевых ресторанов., объединение вкуса и формы продукта, снижение эксплуатационных сложностей и затрат на кухнях магазинов.

При необходимости линия может корректировать производственные мощности и характеристики упаковки., таким образом, мы сможем массово производить фрикадельки, подходящие для супермаркетов, и дополнительно обеспечим стабильные поставки и свежесть на полках..

Стандартизированные фрикадельки, производимые на производственной линии, легко хранить и транспортировать., адаптация к потребностям централизованного складирования и межрегионального распределения распределительных центров, сокращение потерь.

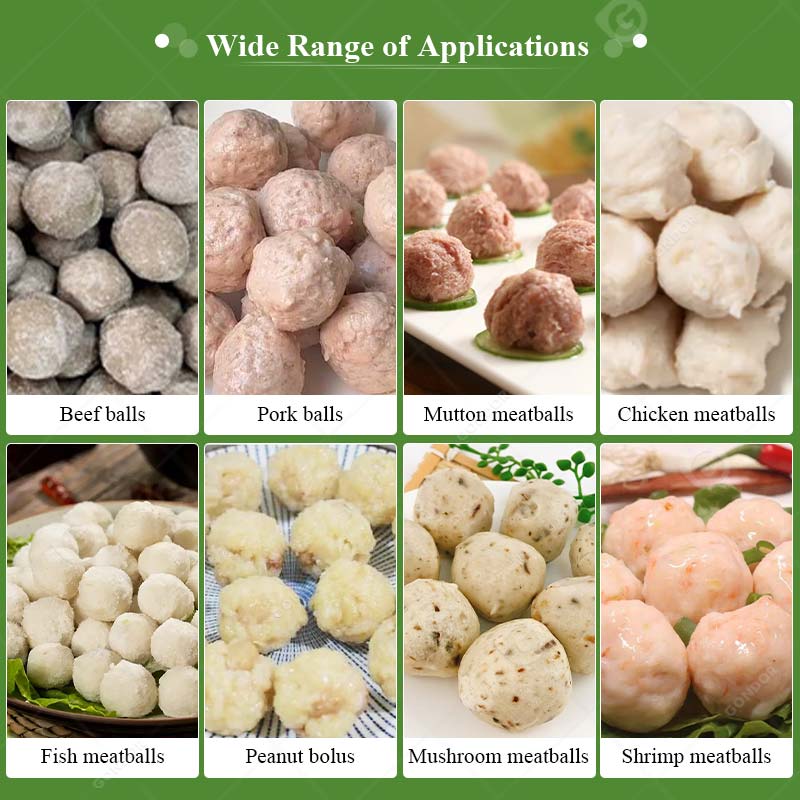

Сырье, подходящее для машины для изготовления фрикаделек Гондора

Линия позволяет производить различные виды фрикаделек., включая говяжьи шарики, свиные шарики, рыбные шарики, куриные шарики, и фаршированные фрикадельки. С возможностью жарки или бланширования, он поддерживает различные стили обработки для удовлетворения разнообразных потребностей рынка, таких как ингредиенты для горячих блюд, быстрое питание, готовые блюда, и замороженные розничные продукты.

>

Особенности оборудования для переработки фрикаделек Гондора

Полностью автоматизированное и высокоэффективное производство

От переработки сырья до выпуска готовой продукции, весь процесс автоматизирован, значительное сокращение ручного вмешательства и значительное повышение эффективности производства фрикаделек и производительности в единицу времени.

Стабильный, Униформа, И контролируемое качество

Стандартизированные процессы и точный контроль параметров обеспечивают стабильный вкус., размер, и эластичность в каждой партии фрикаделек, повышение признания рынка.

Гибкая конфигурация, адаптируемая к различным процессам

Поддержка дополнительных машин непрерывного обжаривания или бланширования., позволяет гибко переключаться между жаркой и бланшированием как двумя основными процессами для удовлетворения производственных потребностей в фрикадельках с разными вкусами..

Значительное снижение общих затрат

Автоматизация снижает трудоемкость, оптимизирует потребление энергии и использование материалов, и снижает процент дефектов, сокращение общей стоимости производства фрикаделек по нескольким параметрам.

Линия по производству фрикаделек Гондора включает в себя оборудование

Машина для измельчения замороженного мяса

Мясорубки замороженные перерабатывать замороженное мясо напрямую — предотвращает рост микробов, сохраняет свежесть/безопасность, и дает однородные гранулы для оптимального измельчения.

Машина для резки чаши

Ядро линии: смешивает мясной фарш с добавками/льдом/крахмалом; высокоскоростные лезвия эмульгируют для извлечения солерастворимых белков для нежности, эластичная паста.

Машина для формирования фрикаделек

The машина для формирования фрикаделек автоматически производит фрикадельки одинакового размера и веса — размер порции можно регулировать, эффективность стабильна, и устраняются несоответствия ручного управления.

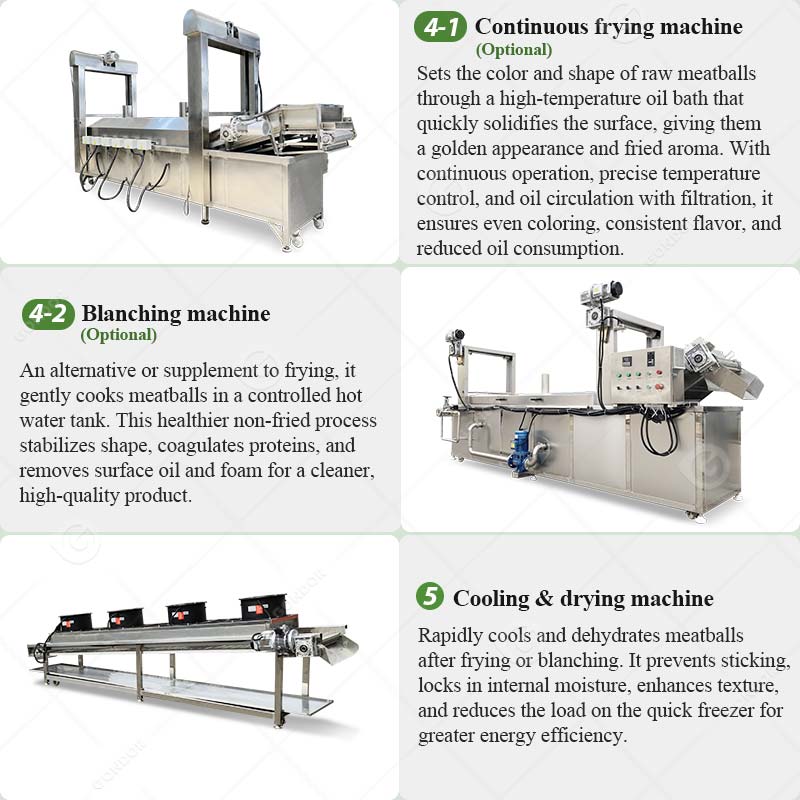

Дополнительная машина непрерывного обжаривания

Высокотемпературная масляная ванна придает золотистую форму., ароматные фрикадельки — точный контроль температуры, фильтрация масла, низкое энергопотребление.

Дополнительная бланшировочная машина

Нежареная альтернатива: приготовление контролируемой горячей воды — стабилизирует форму, коагулирует белок, качественно удаляет масло/пену.

Охлаждение & Сушильная машина

Охлаждает/сушит после жарки/бланширования — предотвращает прилипание, запирает влагу, улучшает текстуру, снижает нагрузку на морозильную камеру.

Туннельная морозильная машина

-35℃ поток холодного воздуха быстро замерзает (ядро ≤-18℃)—

Туннельные морозильники сохранить еду свежей и сочной, подавлять рост бактерий, и продлить срок годности.

Почему стоит выбрать наше оборудование?

- Обширный ассортимент продукции: Производит говяжьи шарики, свиные шарики, рыбные шарики, и многое другое, удовлетворение разнообразных потребительских предпочтений.

- Процесс жарки для различных сценариев: Дополнительная технология жарки позволяет получить хрустящие фрикадельки., идеально удовлетворяет потребности рынка фаст-фуда и готовых к употреблению блюд.

- Специальное решение для бланширования: Использует процесс бланширования, чтобы сохранить первоначальную свежесть ингредиентов., идеально подходит для приготовления горячих блюд и производства здоровой пищи.

- Поддержка настройки замороженной розничной торговли: Совместимость с процедурами обработки замороженными продуктами., производство фрикаделек, которые долговечны и удобны для транспортировки, удовлетворение потребностей в поставках замороженных каналов розничной торговли.

- Поддержка настройки логотипа и модели: С более чем 20 многолетний опыт работы в производстве пищевого оборудования, мы можем настроить машины под вашу желаемую модель и добавить ваш логотип.