طلاء فعال لإنتاج الغذاء عالي الجودة

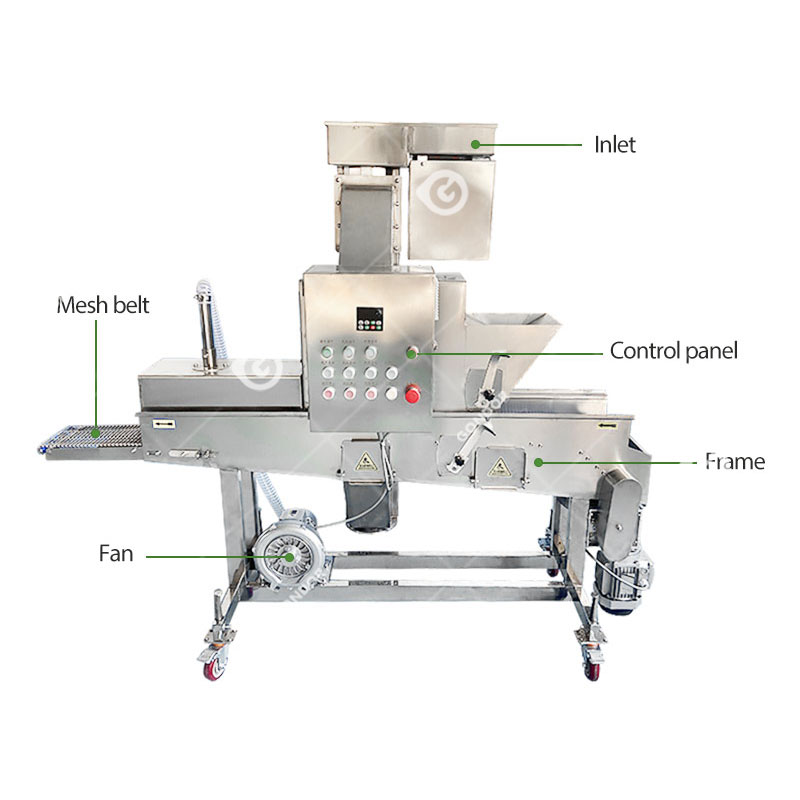

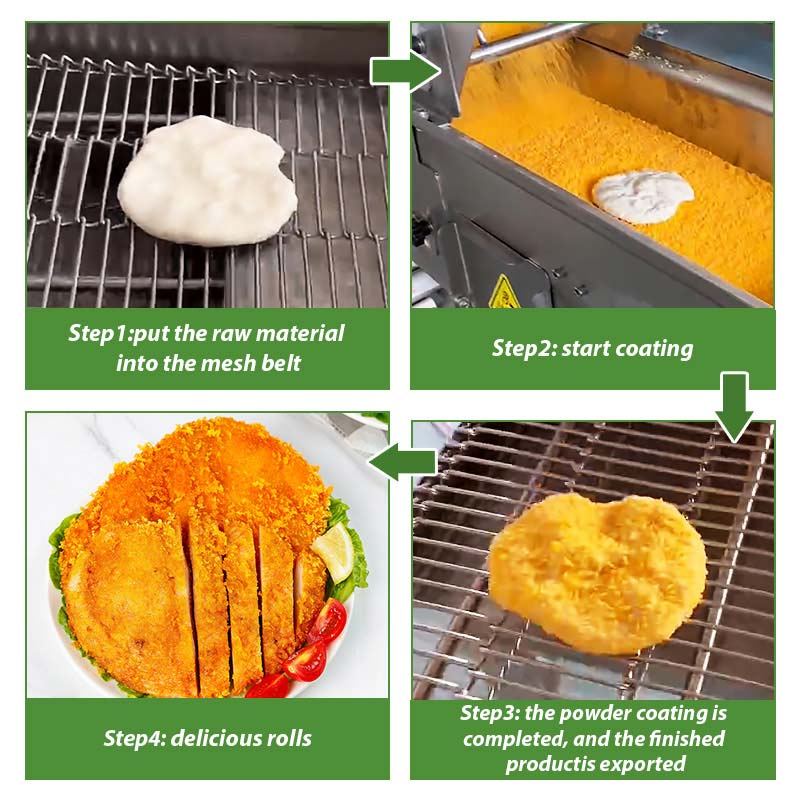

جوندور ماكينة تحميص الدجاج الأوتوماتيكية هو جهاز مصمم خصيصًا لتطبيق طبقة متسقة وموحدة من طبقة النخالة أو فتات الخبز على المنتجات الغذائية المختلفة. يشتمل بنائها القوي عادةً على منفذ تلقيم للتلقيم, نظام ناقل متزامن, آلية نشر النخالة عالية الكفاءة, ومنفذ تفريغ منظم. قيد التشغيل, يتم إدخال المواد الغذائية عند نقطة التغذية ويتم نقلها بشكل ثابت إلى الأمام بواسطة الناقل. يضمن التصميم المبتكر إمداد الفتات بشكل مستمر من القادوس العلوي ووضعه بشكل استراتيجي على طول الحزام الشبكي, تغليف المنتج من زوايا متعددة لإتمامه, 360-تغطية درجة.

| نموذج | جي دي-200 | جي دي-400 | جي دي-600 |

| عرض الحزام | 200مم | 400مم | 600مم |

| قوة | 0.86كيلووات | 3.7كيلووات | 3.7كيلووات |

| مقاس | 1720*650*1400مم | 2638*1050*2280مم | 2638*1050*2280مم |

| وزن | 230كجم | 450كجم | 620كجم |

الصناعات المتعلقة باستخدام آلة الخبز الأوتوماتيكية جوندور

فوائد كبيرة لآلة تحميص الدجاج جوندور

تحسين جودة المنتج

تأكد من أن فتات الخبز ملتصقة بالتساوي, بحيث يكون للمنتج النهائي مظهر متناسق وطعم أفضل, وبالتالي تحسين القدرة التنافسية للسوق للمنتج.

زيادة تنوع المنتجات

يمكن تعديل سمك الطلاء وصيغته وفقًا للاحتياجات المختلفة, ويمكن إنتاج منتجات ذات نكهات وأنماط مختلفة لتلبية مجموعة واسعة من احتياجات السوق.

توفير الطاقة وحماية البيئة

يعمل وضع التشغيل الفعال على توفير الطاقة نسبيًا, تلبي متطلبات التنمية المستدامة, ويقلل من تكاليف التشغيل على المدى الطويل.

تحسين كفاءة الإنتاج

يمكنها تغطية الطعام بسرعة وبشكل متساوٍ بفتات الخبز, تقصير وقت المعالجة بشكل كبير, وزيادة الناتج لكل وحدة زمنية.

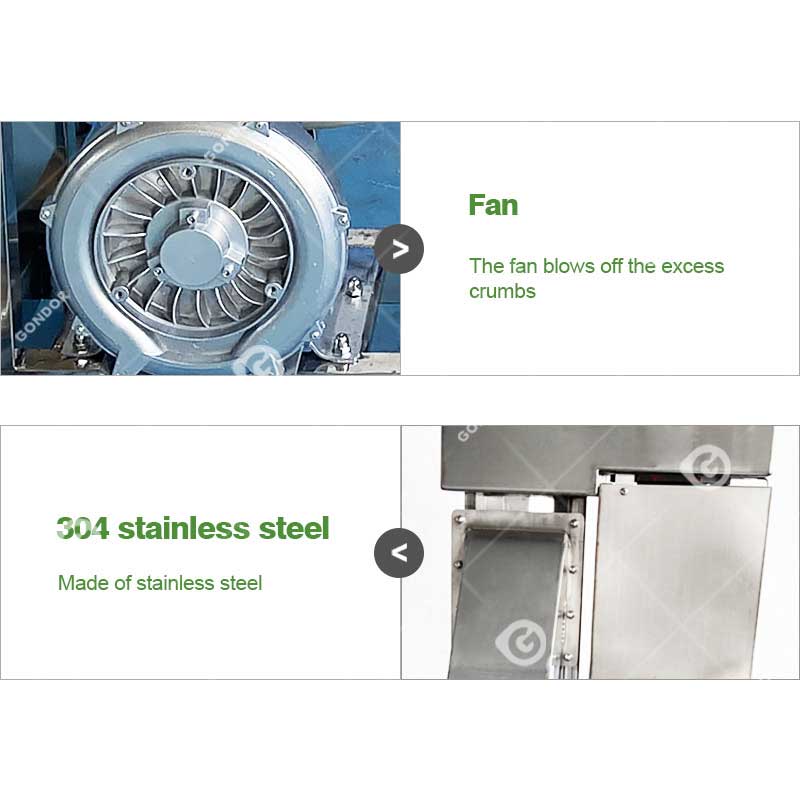

حفظ المواد الخام

ضبط كمية فتات الخبز, ثم قم بتفجير الفتات الزائد من خلال نظام رياح قوي.

آمنة ودائمة

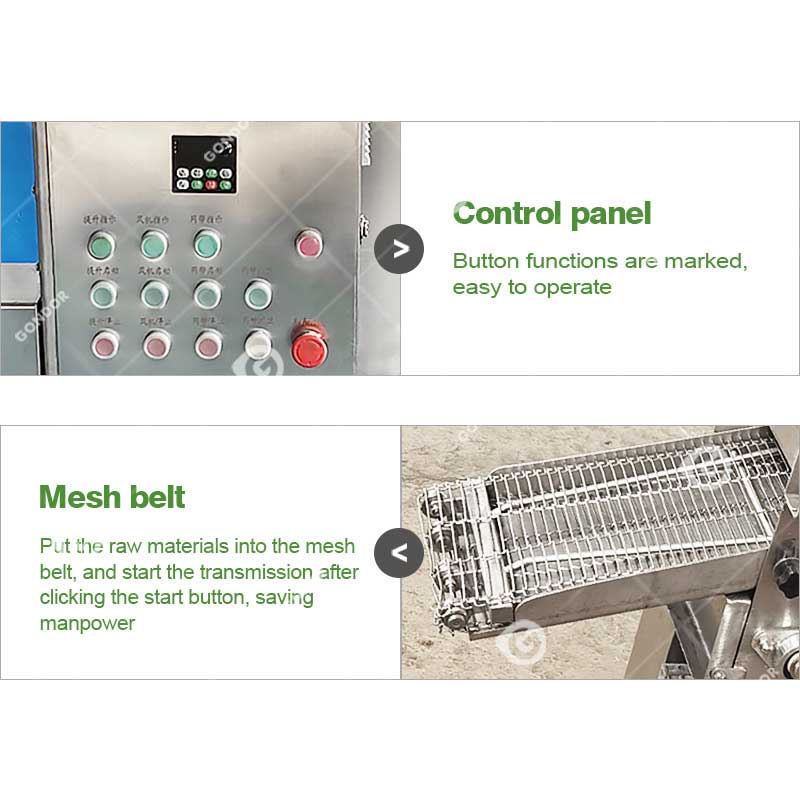

مصنوعة من الفولاذ المقاوم للصدأ, هيكل معقول, عمر خدمة طويل. أداء جيد لحماية السلامة وتشغيل بسيط.

بناء خط إنتاج كامل للطلاء والقلي

تعتبر آلة طلاء فتات الخبز مكونًا أساسيًا في خطوط تجهيز الأغذية, مع أقصى قدر من الكفاءة المحققة من خلال التكامل السلس مع المعدات الأولية والنهائية. من خلال التخطيط العلمي, يمكن إنشاء نظام إنتاج مستمر آلي للغاية.

تكامل معدات المعالجة المسبقة:

- آلة تشكيل الفطائر الأوتوماتيكية: يعالج اللحوم النيئة إلى أشكال موحدة (على سبيل المثال, فطائر مستديرة) ويغذيها مباشرة على آلة الطلاء عبر سيور النقل, ضمان أبعاد موحدة لطلاء ثابت.

- المغطي الخليط: قبل الخبز, يغطي أسطح الطعام بالتساوي باستخدام الخليط السائل (خليط الدقيق أو غسل البيض) كمادة لاصقة لضمان التصاق آمن للخبز.

تكامل معدات ما بعد المعالجة:

- ماكينة القلي المستمر: يدخل الطعام المغطى إلى خط القلي مباشرة, تخضع للتشكيل والطهي في درجات حرارة وأوقات محددة مسبقًا لتكوين لون ذهبي, قشرة مقرمشة.

- خط الخبز بالهواء الساخن (بديل صحي): للمنتجات قليلة الدسم, قم بتوصيله بمعدات الخبز التي تستخدم الهواء الساخن بدلاً من الزيت لطهي أكثر صحة.

- IQF نفق التجميد: عند إنتاج الوجبات الجاهزة المجمدة, تدخل المنتجات المقلية/المخبوزة على الفور إلى نفق التجميد السريع للاحتفاظ بالعصائر والنكهة.

ماكينة تقطيع الدجاج الأوتوماتيكية جوندور – لا غنى عنه للحصول على ترقيات لذيذة

إذا كنت لا تزال تبحث عن آلة تحميص الدجاج الأوتوماتيكية, تعتبر Gondor Machinery خيارك الأفضل لتحسين جودة المنتج! إن آلة تغطية الخبز الأوتوماتيكية الخاصة بنا سهلة التشغيل ولها طلاء موحد, والتي يمكن أن تضيف جاذبية جذابة لطعامك. التحكم الدقيق يوفر المواد الخام, والتشغيل الفعال يزيد الإنتاج. علاوة على ذلك, نحن نقدم خدمة ما بعد البيع عالية الجودة, لذلك لا داعي للقلق بشأن ذلك. اختيار جوندور يعني اختيار الكفاءة والجودة. تعال وشرائه وابدأ رحلة جديدة من اللذة!