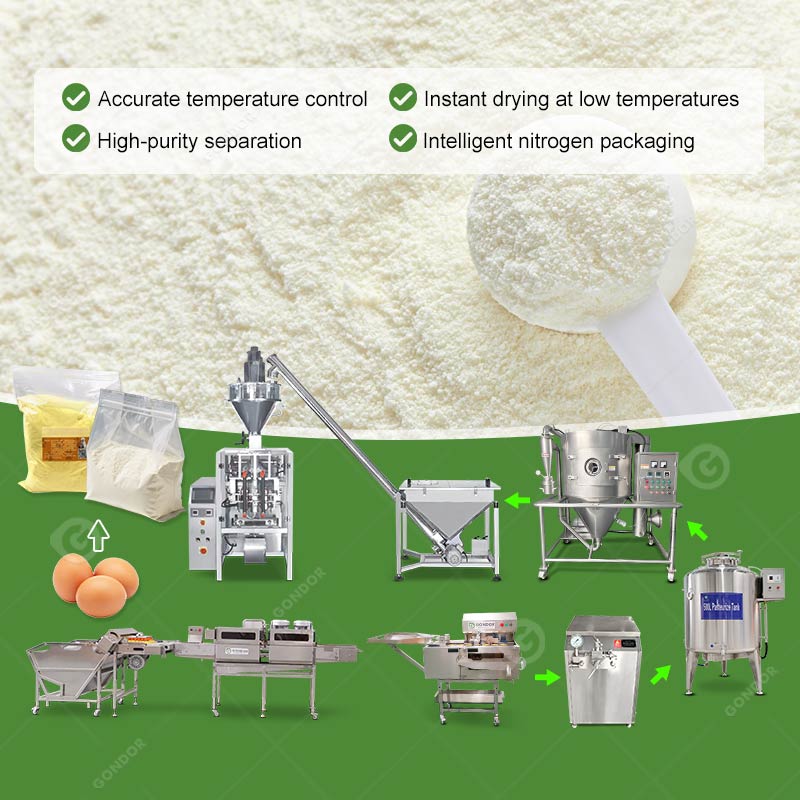

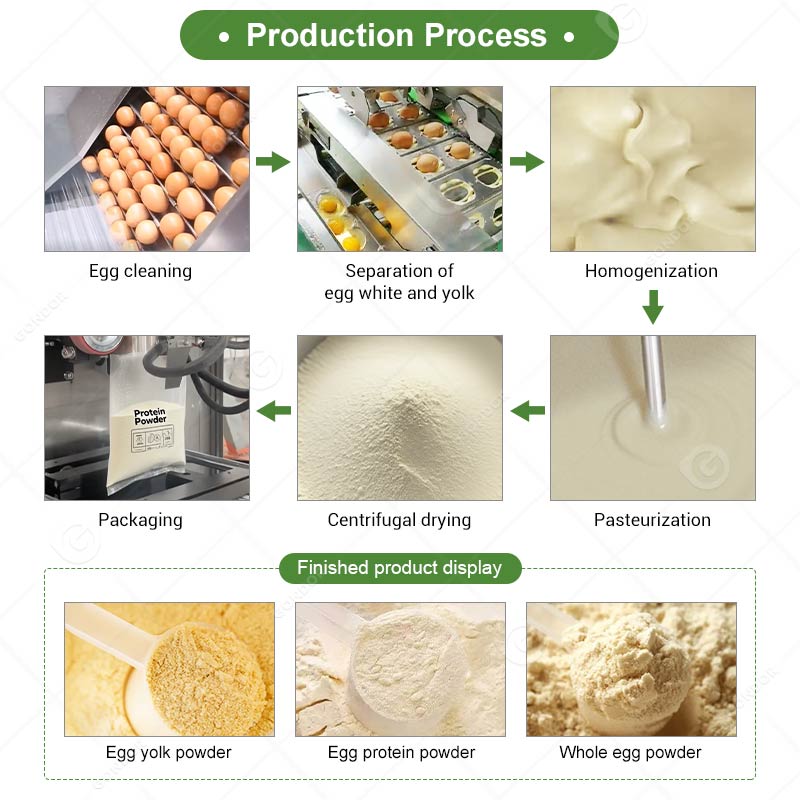

ال خط انتاج مسحوق البيض هو متقدم, نظام آلي مصمم خصيصًا لتحويل البيض الطازج إلى مسحوق بيض عالي الجودة. من خلال التحكم الدقيق في درجة الحرارة, فصل عالي النقاء, وتجفيف الرش بدرجة حرارة منخفضة, يحتفظ النظام بالكامل بتغذية ووظيفة مسحوق البيض. يدمج الخط بأكمله العديد من العمليات مثل تنظيف البيض, الانفصال, التجانس, بسترة, والتعبئة الذكية. لذلك, إنها مناسبة جدًا لشركات الأغذية الكبيرة ومصنعي المكملات الغذائية. فضلاً عن ذلك, يمكن تكييف هذا النظام بمرونة مع البيض العادي, البيض الغني بالسيلينيوم, أو البيض العضوي. أخيراً, مسحوق بياض البيض, مسحوق صفار البيض, مسحوق البيض الكامل, ويمكن إنتاج مجموعة متنوعة من منتجات مسحوق البروتين المخصصة.

| اسم الآلة | الجهد االكهربى | قوة | مادة | مقاس |

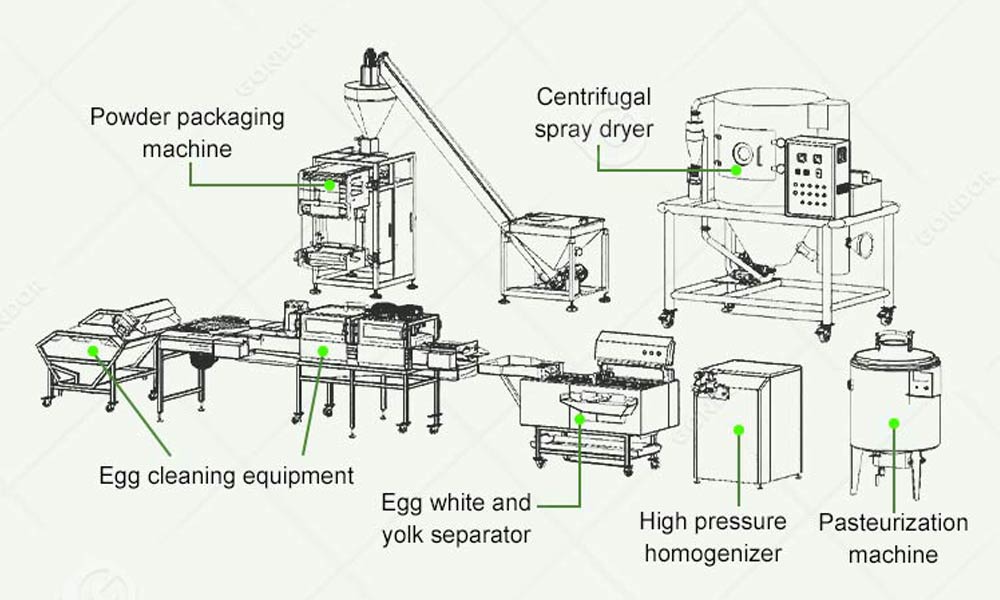

| ماكينة تنظيف وتجفيف البيض | 220V | 2.1كيلووات | الفولاذ المقاوم للصدأ | 2840*550*1400مم |

| فاصل بياض البيض والصفار | 220V | 0.4كيلووات | 1700*980*1280مم | |

| الخالط عالي الضغط | 220V | 2.2كيلووات | 755*520*935مم | |

| آلة البسترة | 380V | 9كيلووات | 1400*800*1400مم | |

| آلة مجفف الرش بالطرد المركزي | 380V | 17.5كيلووات | 2000*900*1900مم | |

| ماكينة تعبئة البودرة اللولبية | 220V | 2.2كيلووات | 1424*980*1343مم |

تطبيقات السوق لخط إنتاج مسحوق البيض

مع تزايد الطلب العالمي على مسحوق البروتين, قيمته الغذائية العالية, ذوبان جيد, والخصائص متعددة الوظائف تعمل على تعزيز التوسع في التطبيقات متعددة الصناعات. يمكن لخط إنتاج مسحوق البروتين أن يساعد الشركات على تلبية الاحتياجات بدقة في المجالات التالية:

المزايا الفائقة لآلة صنع مسحوق البيض

لماذا تختار خط إنتاج بروتين مصل اللبن جوندور?

- التوسع المرن: ويمكنه دعم تحسين القدرات الصغيرة والمتوسطة الحجم أو التحول الآلي للمؤسسات الكبيرة.

- التكيف على نطاق واسع: مناسبة للطعام, المكملات الغذائية, مستحضرات التجميل, وغيرها من الصناعات.

- توافق المواد الخام: يمكنها التعامل مع مجموعة متنوعة من المواد الخام للبيض وإنتاج أشكال مختلفة من المنتجات النهائية بمرونة.

- الامتثال للمعايير: إنه يتوافق مع معايير الجودة والسلامة الدولية ويلبي بسهولة شهادة التصدير.

- الربح المستدام: تحقيق إنتاج مستقر من خلال الأتمتة, خفض التكاليف بشكل كبير, وتحسين الكفاءة, مع عوائد كبيرة.

توصية المعدات

لمساعدة العملاء على تحسين نظام الإنتاج, كما نقوم بتوفير معدات أخرى, مثل:

- خط إنتاج مسحوق الحليب

- آلة التغليف الكرتوني الأوتوماتيكية

من خلال دمج هذه الأنظمة, يمكن لمصنعك تحقيق حل أكثر شمولاً لمعالجة مسحوق البروتين لتلبية المواد الخام المتنوعة وطلب السوق العالمي. سواء كنت في صناعة تجهيز الأغذية, صناعة المكملات الغذائية, أو صناعة مستحضرات التجميل, خط الإنتاج هذا يمكن أن يوفر لك الكفاءة, موثوق, والإنتاجية المستدامة.