बिक्री के लिए गोंडोर स्वचालित तरल भरने की मशीन

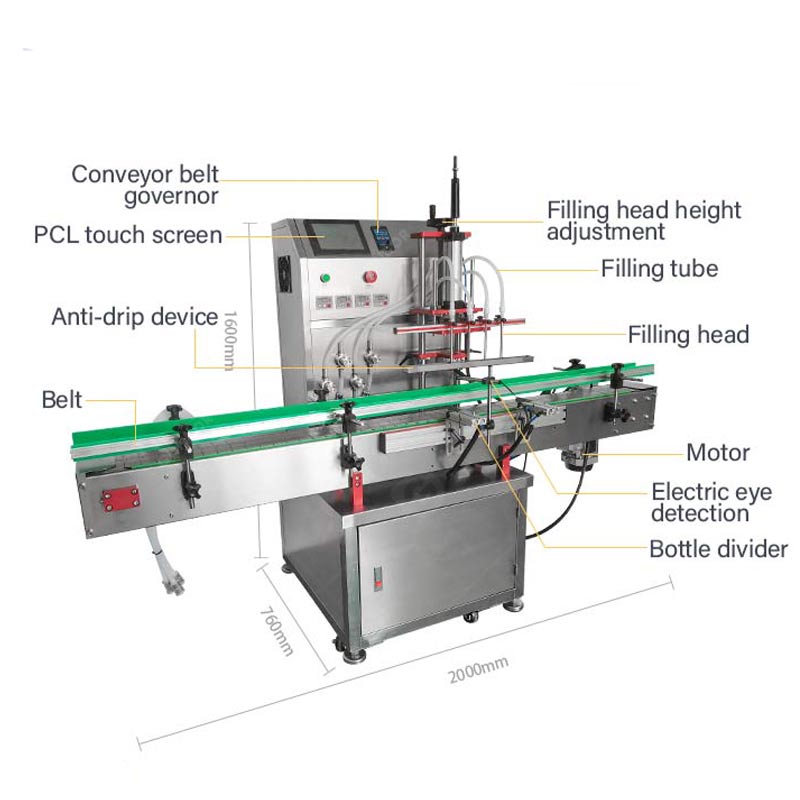

स्वचालित तरल बोतल भरने की मशीन एक अत्यधिक कुशल पैकेजिंग उपकरण है. इसका उपयोग मुख्य रूप से विभिन्न विशिष्टताओं के कंटेनरों में विभिन्न तरल पदार्थों को सटीक रूप से भरने के लिए किया जाता है. इसके अतिरिक्त, हमारे उपकरण आमतौर पर पीएलसी नियंत्रण प्रणाली से बने होते हैं, सिर भरना, संदेश देने वाला सिस्टम, वगैरह.

स्वचालित भरने और कैपिंग विशिष्टता

|

नमूना

|

जीडी-एफएम01

|

नाम

|

स्वचालित भरने की मशीन

|

|

सिर भरना

|

4/6/8/10/12 सिर (अनुकूलित करें)

|

प्रकार

|

सर्वो नियंत्रण पिस्टन भरना

|

|

भरने की सीमा

|

100-5000एमएल (अनुकूलित करें)

|

शुद्धता

|

1%

|

|

रफ़्तार

|

1200-2400 बीपीएच

|

वोल्टेज

|

एसी 220V/50Hz (अनुकूलित करें)

|

|

वायु स्रोत

|

0.5-0.8एमपीए

|

वायु की खपत

|

4KGSx30L/मिनट

|

|

शक्ति

|

2किलोवाट

|

नियंत्रण प्रकार

|

पीएलसी टच स्क्रीन नियंत्रण

|

|

सामग्री

|

फ़्रेम sus304 को अपनाता है, सभी संपर्क भाग suS316L है

|

||

|

आयाम

|

3000*900*2000मिमी

|

वज़न

|

300किग्रा

|

गोंडोर तरल भरने की मशीन का बाजार दायरा

- विभिन्न प्रकार की मदिरा जैसे शराब भरना, बियर, और शराब. उत्पादन दक्षता में सुधार के लिए भरने की मात्रा को सटीक रूप से नियंत्रित किया जा सकता है.शराब

- यह तरल दवाओं को सटीकता से शीशियों में भर सकता है और दवाओं की गुणवत्ता और सुरक्षा सुनिश्चित करने के लिए उन्हें सील कर सकता है.मौखिक तरल

- विभिन्न नेत्र बूँदें, नाक की बूंदों और अन्य तरल दवाओं को भी तरल भरने वाली मशीनों का उपयोग करके भरने की आवश्यकता होती है.आंखों में डालने की बूंदें

- जूस सहित, चाय पेय पदार्थ, कार्बोनेटेड शीतल पेय, वगैरह. तरल भरने वाली मशीनें पेय पदार्थों को विभिन्न पैकेजिंग कंटेनरों में जल्दी और सटीक रूप से भर सकती हैं.पेय

- जैसे सोया सॉस, सिरका, खाना पकाने का तेल, वगैरह. इन तरल मसालों को उत्पाद की गुणवत्ता और स्वच्छता मानकों को सुनिश्चित करने के लिए सटीक भरने वाले उपकरण की आवश्यकता होती है.मसालों

- उपकरण लोशन जैसे सौंदर्य प्रसाधन भर सकता है, शैंपू, दैनिक रासायनिक उत्पादों की बाजार मांग को पूरा करने के लिए विभिन्न पैकेजिंग कंटेनरों में शॉवर जैल और अन्य तरल पदार्थ डालें.प्रसाधन सामग्री

- कुछ तरल क्लीनर, जैसे कपड़े धोने का डिटर्जेंट और बर्तन धोने का तरल, उत्पादन दक्षता और उत्पाद की गुणवत्ता में सुधार के लिए कुशल तरल भरने वाली मशीनों से भरने की आवश्यकता है.सफ़ाईकर्मी

स्वचालित भरने वाली मशीनें अनुप्रयोग परिदृश्य

गोंडोर स्वचालित तरल भरने की मशीन की उत्कृष्ट उपकरण विशेषताएं

उन्नत सेंसर और नियंत्रण प्रणालियों को अपनाकर, भरने की सटीकता और स्थिरता सुनिश्चित करने के लिए भरने की मात्रा को सटीक रूप से नियंत्रित किया जा सकता है.

फिलिंग हेड का संरचनात्मक डिजाइन उचित है, जो यह सुनिश्चित कर सकता है कि भरने की प्रक्रिया के दौरान तरल टपकेगा या छिटकेगा नहीं.

बड़ी संख्या में भरने के कार्य कम समय में पूरे किये जा सकते हैं, जो बड़े पैमाने पर उत्पादन की जरूरतों को पूरा कर सकता है.

उपकरण का सटीक नियंत्रण और निगरानी करें, उत्पादन प्रक्रिया में समस्याओं का समय पर पता लगाना और उनका समाधान करना, और उपकरण का स्थिर संचालन सुनिश्चित करें.

यह सभी प्रकार के तरल पदार्थों के लिए उपयुक्त है, द्वारा संसाधित तरल उत्पाद भी शामिल हैं पाश्चराइज़र, जैसे दूध, रस, पेय, वगैरह।, और अपने शेल्फ जीवन को बढ़ाते हुए अपने पोषक तत्वों और स्वाद को प्रभावी ढंग से बनाए रख सकते हैं.

इसे बोतलों के अनुकूल बनाने के लिए विभिन्न कंटेनर विशिष्टताओं के अनुसार समायोजित किया जा सकता है, डिब्बे, बैरल और विभिन्न आकृतियों और आकारों के अन्य कंटेनर.

आपातकालीन स्टॉप बटन जैसे सुरक्षा सुरक्षा उपकरणों से सुसज्जित. उपकरण के संचालन के दौरान, ये उपकरण उपकरण और ऑपरेटरों की सुरक्षा की रक्षा कर सकते हैं.

गोंडोर स्वचालित तरल बोतल भरने की मशीन – परिशुद्धता भरने में अग्रणी

हमारी स्वचालित तरल भरने की मशीन गोंडोर के संपूर्ण उपकरण का मुख्य उपकरण है तरल भरने की लाइन. यह उच्च गुणवत्ता, अत्यधिक स्वचालित उपकरण प्रत्येक बोतल में सटीक और त्रुटि मुक्त तरल मात्रा सुनिश्चित करता है. पेय पदार्थ में विभिन्न तरल पदार्थ भरने के लिए व्यापक रूप से लागू, दवा, और सौंदर्य प्रसाधन उद्योग, यह सरल संचालन और स्थिरता प्रदान करता है, विश्वसनीय प्रदर्शन. गैंगटुओ फिलिंग मशीन चुनने का मतलब सिर्फ एक उपकरण में निवेश करना नहीं है, लेकिन एक निर्बाध में, उच्च दक्षता वाली उत्पादन प्रक्रिया. यह मशीन हमारी कैपिंग के साथ त्रुटिपूर्ण ढंग से एकीकृत हो जाती है, लेबलिंग, और संपूर्ण उच्च गति वाली उत्पादन लाइन बनाने के लिए पैकेजिंग उपकरण, परिचालन लागत को कम करते हुए आउटपुट को अधिकतम करने में आपकी सहायता करना.