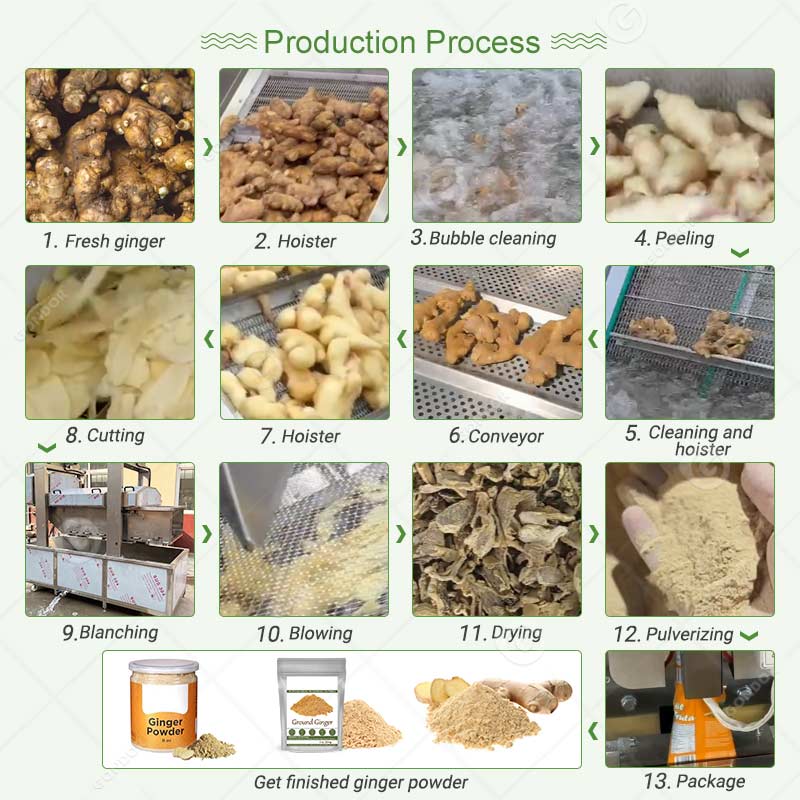

अदरक पाउडर बनाने की मशीन बुद्धि को एकीकृत करने वाली व्यावसायिक उत्पादन प्रणालियों का एक समूह है, उच्च दक्षता, और परिष्कार, जो विशेष रूप से उच्च गुणवत्ता वाले अदरक पाउडर के लिए डिज़ाइन किया गया है, हल्दी पाउडर, और लहसुन पाउडर. उत्पादन लाइन कच्चे माल के रूप में ताज़ा अदरक और लहसुन लेती है, और उन्नत उपकरणों और कठोर प्रौद्योगिकी के माध्यम से, कच्चे माल से तैयार उत्पादों तक स्वचालित उत्पादन की पूरी प्रक्रिया का एहसास होता है, जो खाद्य प्रसंस्करण जैसे कई उद्योगों के लिए मजबूत समर्थन प्रदान करता है, मसाला निर्माण, दवा,ई और दुनिया भर में स्वास्थ्य देखभाल.

| नाम |

वोल्टेज |

शक्ति |

सामग्री |

आकार |

| फहरानेवाला |

380वी 50HZ |

1.5किलोवाट |

स्टेनलेस स्टील |

3000*1200*1600मिमी |

| बबल वॉशिंग मशीन |

3.7किलोवाट |

4000*1400*1300मिमी |

| ऊन रोलर सफाई मशीन |

1.5किलोवाट |

1700*850*850मिमी |

| विसर्जन लहरा |

3.7किलोवाट |

2500*800*1900मिमी |

| बेल्ट चुनें |

1.5किलोवाट |

5000*800*1040मिमी |

| स्लाइसर |

220वी 50HZ |

2.5किलोवाट |

1200*530*1270मिमी |

| ब्लैंचिंग मशीन |

380वी 50HZ |

1.5किलोवाट |

5120x1370x1400मिमी |

| हवा सुखाने की मशीन |

7.5किलोवाट |

4100x1000x1800मिमी |

| सुखाने की मशीन |

17किलोवाट (बिजली की हीटिंग)

2किलोवाट (गैस तापन) |

2800*1500*2000मिमी |

| भुरभुरीकारी |

17.25किलोवाट |

4827*1100*2739मिमी |

| पैकिंग मशीन |

220वी 50HZ |

2.3किलोवाट |

1100*950*2000मिमी |

अदरक प्रसंस्करण मशीन के अनुप्रयोग क्षेत्र

अदरक पाउडर सिर्फ एक मसाला नहीं है, बल्कि स्वस्थ जीवन का प्रतीक भी है. अदरक प्रसंस्करण मशीन का उपयोग उत्पादन के लिए किया जा सकता है:

मसाला उद्योगखाद्य उद्योगफार्मास्युटिकल और स्वास्थ्य उद्योगकॉस्मेटिक उद्योग

जैसे कि अदरक पाउडर मसाला और मसाला मिश्रण.

अदरक की चाय में प्रयोग किया जाता है, अदरक चीनी, पके हुए उत्पाद, तुरंत सूप, वगैरह.

स्वास्थ्य भोजन और हर्बल अर्क के लिए उपयोग किया जाता है.

अदरक पाउडर शैंपू बनाना, त्वचा देखभाल उत्पाद, वगैरह.

यह उत्पादन लाइन सिर्फ अदरक का प्रसंस्करण नहीं करती बल्कि यह विभिन्न मसालों और औषधीय पौधों का भी प्रसंस्करण करती है. चाहे वह लहसुन पाउडर हो, हल्दी पाउडर, या प्याज पाउडर, सिस्टम निर्बाध रूप से अनुकूलित होता है. ऐसी बहुमुखी प्रतिभा के साथ, यह विभिन्न बाज़ार मांगों को आसानी से पूरा करता है.

अदरक पाउडर बनाने की मशीन के मजबूत उत्पादन लाभ

उच्च दक्षता & तेजी से वितरण

अदरक पाउडर उत्पादन लाइन में उत्कृष्ट उत्पादन क्षमता है, जो हर घंटे बड़ी मात्रा में अदरक के कच्चे माल को संसाधित कर सकता है, इस प्रकार शीघ्र ही उच्च गुणवत्ता वाला अदरक पाउडर तैयार हो जाता है. चाहे बड़े ऑर्डर से निपटना हो या दैनिक बाजार आपूर्ति को पूरा करना हो, यह उत्पादन कार्यों को कुशलतापूर्वक पूरा कर सकता है और उद्यमों को बाजार के अवसरों का लाभ उठाने में मदद कर सकता है.

परिशुद्धता तापमान नियंत्रण

उत्पादन लाइन उन्नत-196℃ तरल नाइट्रोजन लॉक ताज़ा तकनीक को अपनाती है, जो सुखाने और पीसने की प्रक्रिया में तापमान और समय को सटीक रूप से नियंत्रित करता है, न केवल जल्दी निर्जलीकरण करता है, बल्कि अदरक के अनूठे मसालेदार स्वाद और वाष्पशील सुगंधित पदार्थों को भी बरकरार रखता है, अदरक पाउडर की समृद्ध सुगंध और शुद्ध स्वाद सुनिश्चित करना.

बढ़िया पीसना & समायोज्य कण आकार

नैनो ग्राइंडिंग तकनीक से लैस, अदरक को अलग-अलग सुंदरता के लिए कुचला जा सकता है, और कण आकार को ग्राहकों के अनुसार लचीले ढंग से समायोजित किया जा सकता है’ आवश्यकताओं, ताकि एक समान और नाजुक पाउडर सुनिश्चित किया जा सके, जो उत्पाद अनुप्रयोग की विविधता और अतिरिक्त मूल्य को काफी हद तक बढ़ाता है.

स्वच्छता & खाद्य सुरक्षा

उत्पादन लाइन पूरी तरह से बंद है, और मुख्य भाग खाद्य-ग्रेड स्टेनलेस स्टील से बने होते हैं, जो प्रभावी रूप से क्रॉस-संदूषण को रोकता है. उत्पादन प्रक्रिया में मल्टी-स्टेज धूल हटाने और सफाई प्रणाली स्थापित की गई है, के साथ 99.99% नसबंदी दर, शून्य धूल रिसाव को प्राप्त करना, उत्पाद की स्वच्छता और सुरक्षा को सख्ती से सुनिश्चित करना, और अंतरराष्ट्रीय खाद्य सुरक्षा मानकों को पूरा करना.

लचीला विन्यास

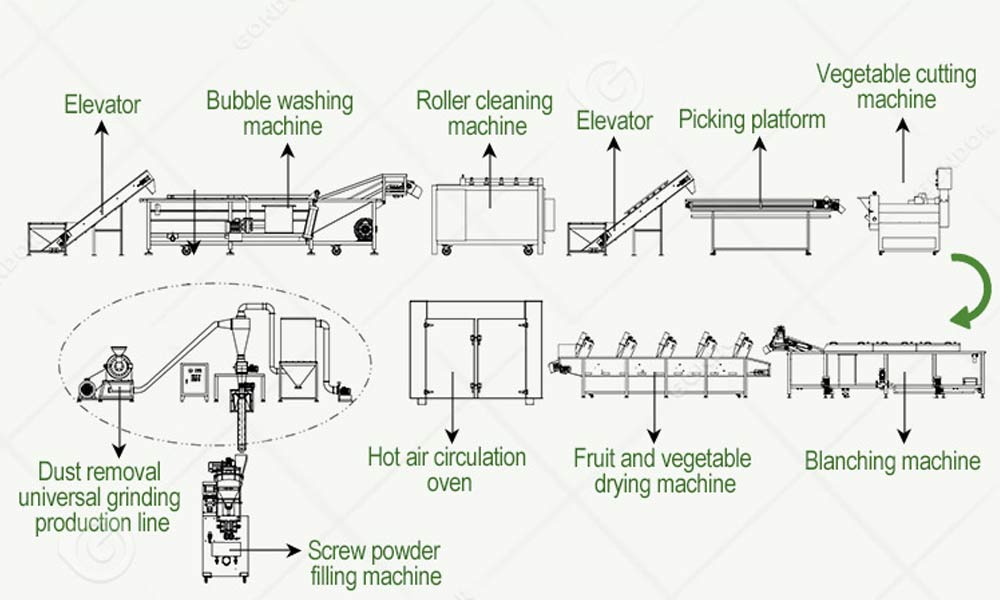

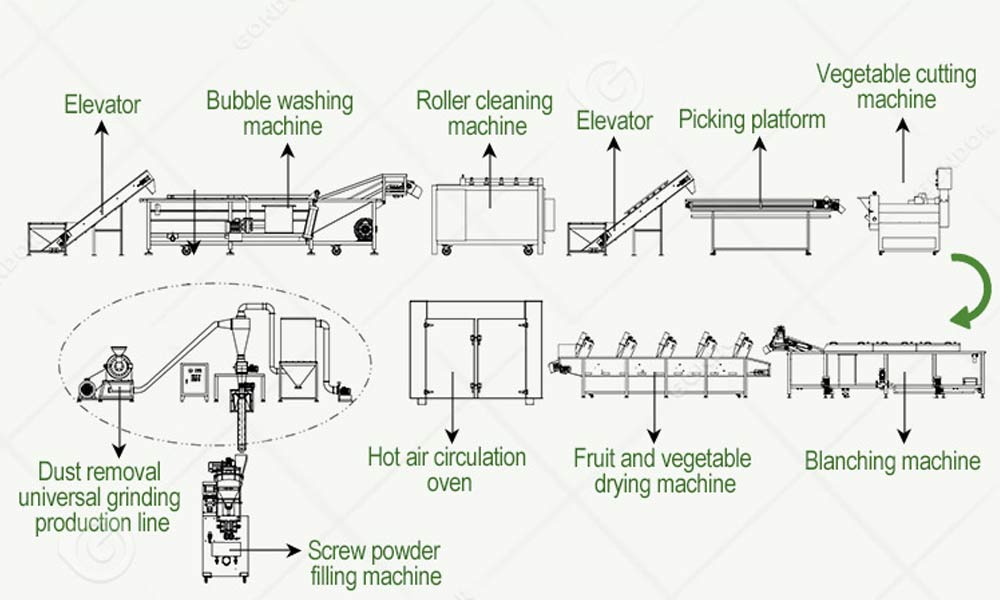

पूरी श्रृंखला के उपकरण जैसे सब्जी धोने की मशीन, ब्रश सफाई मशीन, अदरक काटने वाला, गर्म हवा परिसंचरण ड्रायर, धूल रहित ग्राइंडिंग लाइन,

पेंच पाउडर भरने की मशीन, वगैरह. विभिन्न उत्पादन क्षमता और प्रक्रिया आवश्यकताओं को पूरा करने के लिए ग्राहकों की वास्तविक जरूरतों के अनुसार लचीले ढंग से मिलान किया जा सकता है.

अनुकूलित विन-विन समाधान

कुशल सफ़ाई से, सटीक कटाई, और बुद्धिमान सुखाने से लेकर बारीक पीसने और सड़न रोकने वाली पैकेजिंग तक, अदरक पाउडर बनाने की मशीन न केवल उच्च गुणवत्ता वाले अदरक पाउडर के उत्पादन के लिए एक शक्तिशाली उपकरण है, बल्कि यह आपके लिए अंतर्राष्ट्रीय बाज़ार में प्रवेश करने और ब्रांड प्रतिस्पर्धात्मकता बढ़ाने के लिए एक ठोस समर्थन भी है. यदि आप अदरक पाउडर उत्पादन लाइन या अन्य संबंधित मसाला प्रसंस्करण उपकरण में रुचि रखते हैं, जैसे कि लहसुन प्रसंस्करण लाइन, मिर्च सॉस उत्पादन लाइन, वगैरह।, अधिक उत्पाद समाधान और कोटेशन जानकारी प्राप्त करने के लिए कृपया किसी भी समय हमसे संपर्क करें, और वैश्विक बाजार में संयुक्त रूप से नए अवसर तलाशेंगे!