Ruota per temperare il cioccolato: Preciso & Alta qualità

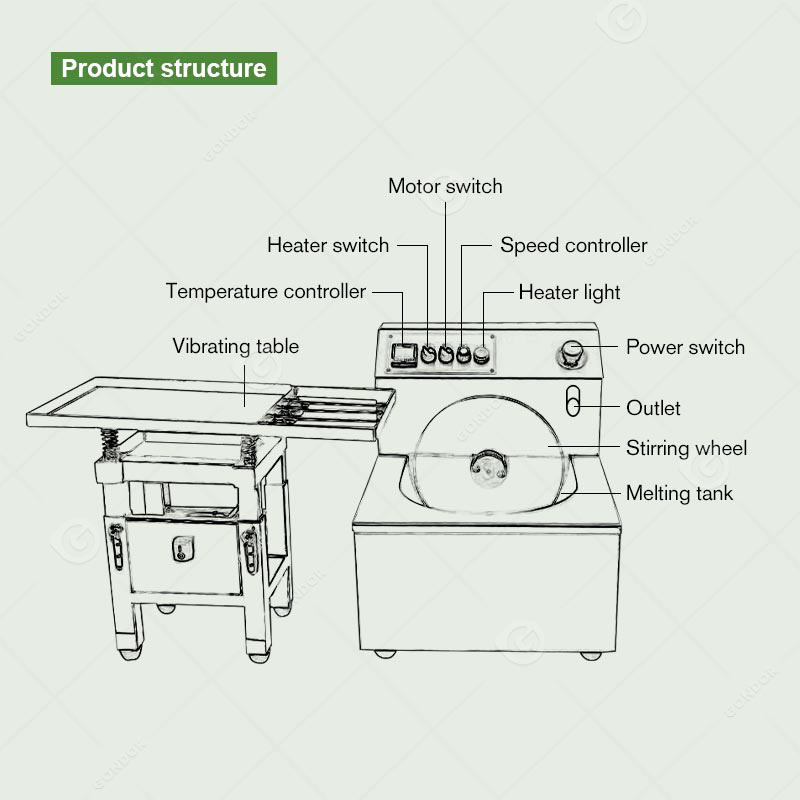

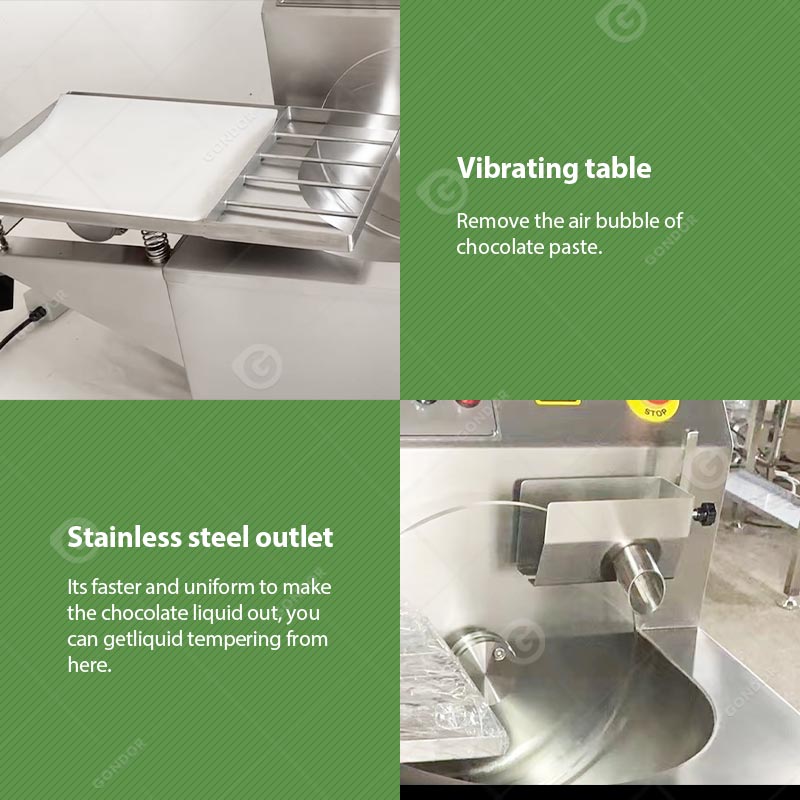

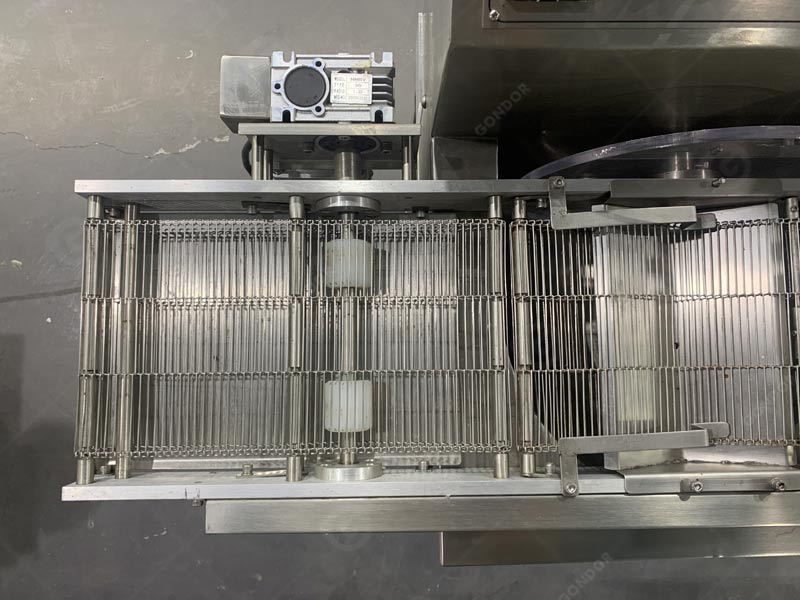

Questo ruota per temperare il cioccolato, progettato per impianti di trasformazione alimentare e industria dolciaria, presenta un processo di trafilatura completamente in acciaio inossidabile conforme agli standard internazionali di sicurezza alimentare. Inoltre, dispone di sensori Siemens per un controllo preciso della temperatura e un'efficiente conservazione del calore, garantendo un temperaggio uniforme del cioccolato e una struttura cristallina stabile. Inoltre, la macchina include una ruota di agitazione automatica e una funzione di vibrazione, che rimuove efficacemente le bolle, risultando in una superficie liscia e facile sformatura. Grazie al suo design compatto e flessibile, è facile da installare, mentre il semplice pannello operativo lo rende adatto a varie esigenze di produzione del cioccolato. Finalmente, la combinazione perfetta del sistema di controllo della temperatura e dell'uscita in acciaio inossidabile garantisce che il cioccolato scorra in modo uniforme e delicato, rendendo questa macchina la scelta ideale per coloro che danno priorità alla produzione di cioccolato di alta qualità.

Temperatrici per ruote di cioccolato Gondor

|

Modello |

Capacità | Energia | Voltaggio | Misurare |

| GD-CMPM-08/15 | 5kg-60kg/ora | 0.6-2kw | 220v |

450*550*550mm-1220*780*1290 mm |

|

GD-CMPM-30/60 |

10kg-40kg/ora | 1.8-2kw | 220v |

900 * 670 *1230mm-1130 * 750*1300mm |

| GD-CMPM-15*2 | 10-30kg/h | 2kw | 220v |

1070*600*640mm |

|

GD-CMPM-24 |

15-45kg/h | 2.2kw | 220v |

1275* 660 *570mm |

Mercati presi di mira dalla temperatrice con ruota di cioccolato

Questa temperatrice per ruote di cioccolato è ampiamente utilizzata in una varietà di scenari di produzione del cioccolato grazie alla sua avanzata tecnologia di controllo della temperatura, precisa progettazione strutturale, e un processo di produzione che soddisfi gli standard di sicurezza alimentare. Non è solo adatto alla produzione su larga scala, ma può anche soddisfare le esigenze di personalizzazione di alta qualità. È l'attrezzatura ideale nel campo della produzione del cioccolato. Di seguito sono riportati i principali mercati target di questa apparecchiatura:

Vantaggi tecnici unici della temperatrice Gondor Wheel

La ruota per temperare il cioccolato Gondor si distingue tra le attrezzature per la produzione del cioccolato grazie al suo squisito processo di produzione e alle caratteristiche tecniche avanzate. Che si tratti di prestazioni, progetto, o l'esperienza dell'utente, mostra vantaggi unici, può soddisfare diverse esigenze produttive, e offre agli utenti un'esperienza di produzione efficiente e di alta qualità. Di seguito sono riportati i vantaggi tecnici unici di questa apparecchiatura:

Ruota per temperare il cioccolato – La perfetta combinazione di qualità ed efficienza

Questa ruota per temperare il cioccolato è appositamente progettata per la lavorazione di caramelle e alimenti. Adotta un corpo in acciaio inossidabile e un preciso sistema di controllo della temperatura per garantire un temperaggio uniforme e un rivestimento fine del cioccolato. La sua funzione automatica di agitazione e vibrazione può migliorare efficacemente la lucentezza della superficie e l'effetto di sformatura, ed è facile da usare e adattarsi a esigenze di produzione diversificate. Se è necessario costruire una linea di produzione completa, può essere utilizzato con a mulino a sfere per cioccolato per la macinazione fine delle materie prime, o combinato con a macchina per ricoprire il cioccolato per realizzare un processo di rivestimento continuo. Non esitare a contattarci per una soluzione personalizzata.