Macchina per pastorizzazione a bagnomaria per imballaggio alimentare

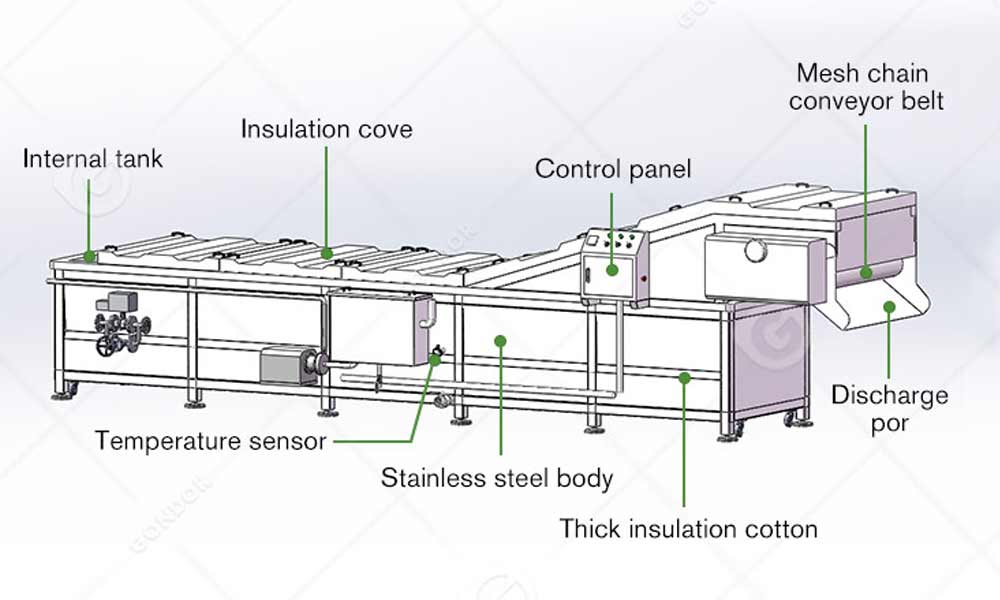

UN Pastorizzatore a bagnomaria è un sistema di automazione avanzato. È la scelta ideale per la lavorazione degli alimenti sensibili al calore per realizzare un funzionamento continuo attraverso un controllo preciso della temperatura. È realizzato in resistente acciaio inossidabile SUS304, dotato di PLC e dispositivo di controllo touch screen, che può facilmente regolare i parametri di sterilizzazione garantendo al contempo un funzionamento stabile. Inoltre, il sistema di recupero del calore e di filtraggio automatico a risparmio energetico dello sterilizzatore da bagno riduce il consumo energetico, garantisce un riscaldamento uniforme, e prolunga la durata di conservazione.

Specifiche del pastorizzatore a bagnomaria

| Pastorizzatore a bagnomaria | |

| Metodo di riscaldamento | riscaldamento a vapore |

| Tempo di sterilizzazione | 3-60 minuti (regolabile) |

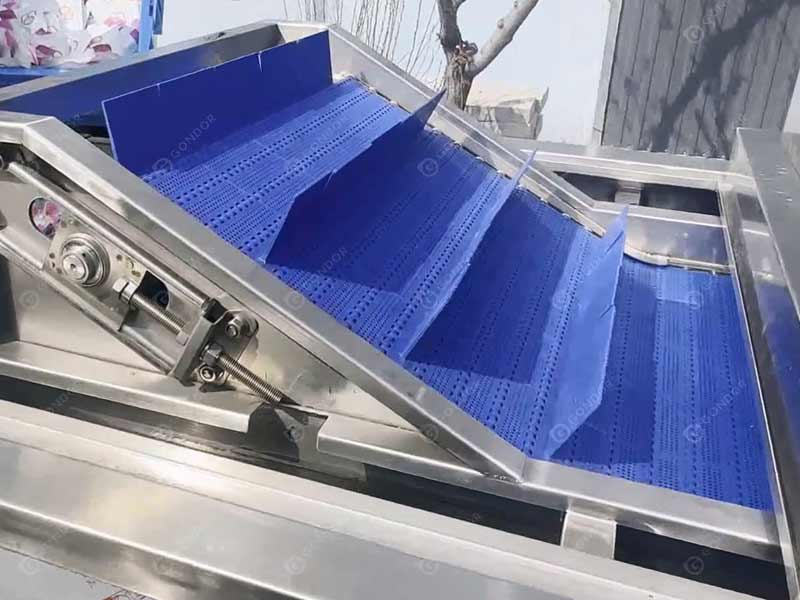

| Cintura a rete | doppio strato |

| Elaborazione | Riscaldamento + Pastorizzazione+Raffreddamento |

| Applicazione | Pastorizzatore per confezioni in bottiglia/sacchetto |

| Adatto per | Fabbrica di pastorizzazione di bevande/alimenti |

| Volume | Regolabile |

| Materiale | 304 Acciaio inossidabile,Personalizzato |

| Certificazione | ISO 9001, ISO 14001, ISO 45001, CE, BSCI, ETL |

Industria servita dal pastorizzatore a bagnomaria

Il pastorizzatore a bagnomaria è ampiamente utilizzato nell'industria globale della lavorazione di alimenti e bevande. Che si tratti di un piccolo produttore o di una grande fabbrica industrializzata, le attrezzature possono soddisfare esigenze diversificate e supportare varie forme di imballaggio come l'insacco, imbottigliamento, inscatolamento, e pallettizzazione.

Principali aree di applicazione

Latte, yogurt, formaggio, e altri prodotti lattiero-caseari sono più sicuri dopo la pastorizzazione, pur mantenendo il sapore fresco.

Succo di frutta, bevande proteiche vegetali, e le bevande alle erbe possono ottenere una sterilizzazione uniforme mantenendo il gusto naturale.

Tutti i tipi di salse, zuppe, e le verdure preparate possono mantenere il loro sapore e la loro consistenza dopo la sterilizzazione a bassa temperatura.

Verdure pulite confezionate, verdure in salamoia, frutti conservati, e altri prodotti possono essere sterilizzati in modo sicuro e conservare la nutrizione.

Caratteristiche notevoli delle apparecchiature per la pastorizzazione a vapore

Soluzioni correlate alla lavorazione degli alimenti

Oltre al pastorizzatore a tunnel, forniamo anche una gamma completa di attrezzature complementari per linee complete di lavorazione alimentare, compreso:

- Macchina per l'essiccazione dell'aria – Per stabilizzare la temperatura del prodotto dopo la sterilizzazione.

- Macchina sottovuoto a doppia camera-Prolungare la durata di conservazione dei prodotti.

- Sterilizzatore a storta-Adatto per il trattamento di prodotti che richiedono temperature più elevate.