Добрая весть! Гондор информирует вас о последних новостях проекта.. Проект для автоматическая линия по производству колбасы для продажи в Венесуэле продвигается плавно! Мы настраиваем полностью автоматизированную линию по производству колбасных изделий для венесуэльских клиентов в соответствии с их производственным спросом.. Сейчас, тот линия по производству колбасы решение теперь адаптировано и изготовлено, и он готов к отправке. После прибытия всех машин на производственную площадку заказчика, мы наймем профессионального технического инженера, который проведет установку онлайн! Пожалуйста, не стесняйтесь обращаться к нам, когда вы планируете купить какое-либо оборудование для пищевой промышленности.. И мы предоставим вам самые профессиональные решения.

Проект автоматической линии по производству колбас в Венесуэле

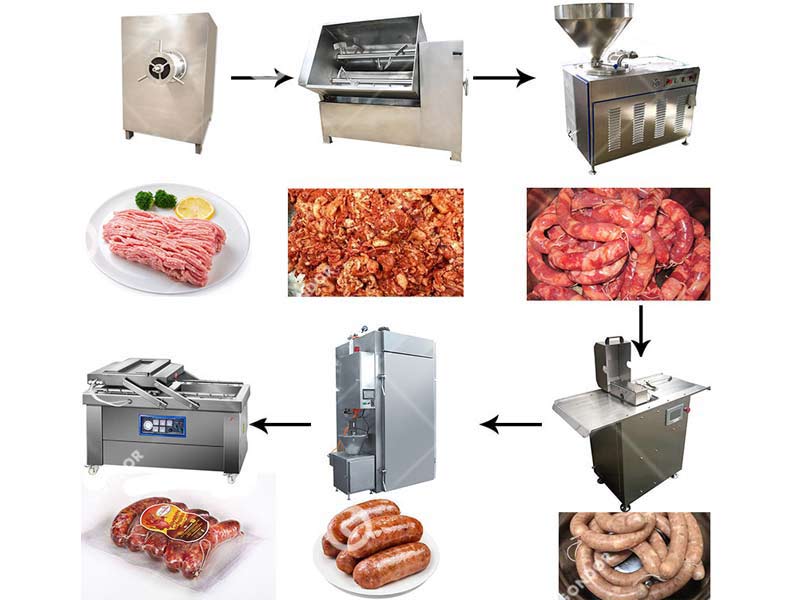

Подробная информация об автоматической линии по производству колбас в Венесуэле

На машинах Гондора, мы можем гарантировать, что каждая колбаса будет нашей передовой автоматическая линия по производству колбасы производит продукцию высочайшего качества. Более того, он разработан с использованием точных технологий, которые могут оптимизировать процесс производства колбас и сделать его идеальным выбором для крупномасштабного производства колбас.. Кроме, с новейшими системами автоматического управления, наши производственные линии не только повышают эффективность производства, но и гарантировать однородность каждой партии колбас. Тем временем, с минимальным участием человека, мы можем поддерживать высокие стандарты гигиены. Свяжитесь с нами для получения более подробной информации о продукте здесь!

- Мясорубка

- Резак для мясной миски

- Миксер для измельчения мяса

- Машина для наполнения колбас

- Машина для обвязки колбас

- Коптильня Духовка

- Вакуумная упаковочная машина

- Корпус из нержавеющей стали SUS304

- Автоматическое заполнение и связывание

- Регулируемые настройки скорости

- Интегрированное смешивание и измельчение

- Точный контроль порций

- Легкая в очистке конструкция

- Энергоэффективная работа

- Усовершенствованные механизмы безопасности

- Новейшая автоматизированная система

- Доступны настраиваемые решения

- Однородный размер и форма колбасы

-

- Общее количество машин линии: 7 наборы

- Материал: SUS304 Нержавеющая сталь

- Основные компоненты: ПЛК, Несущий, Мотор, Механизм

- Уровень автоматизации: Полностью автоматизированный

- Источник питания: Гидравлический/Электрический

- Власть: 30кВт

- Напряжение: 220В/380В

- Масса: 2795кг

- Емкость: 100-500кг/ч

- Сертификация: ИСО 9001, ИСО 14001, ИСО 45001, CE, Бакалавриат наук, ЭТЛ

- Сертификация: ИСО 9001, ИСО 14001, ИСО 45001, CE, Бакалавриат наук, ЭТЛ

Процесс сотрудничества в проекте линии по производству колбас в Венесуэле

Вот краткий процесс сотрудничества по проекту индивидуальной автоматической линии по производству колбас в Венесуэле.! Пожалуйста, свяжитесь с нами, чтобы узнать о проекте в Венесуэле.!

Предыстория проекта в Венесуэле

После общения с этим клиентом, мы знаем, что он руководит предприятием, которое специализируется на производстве высококачественной мясной продукции и имеет многолетний богатый производственный опыт.. Повысить эффективность производства и качество продукции., они решили внедрить продвинутый автоматическая линия по производству колбасы. После многочисленных исследований и сравнений, в конечном итоге он выбрал Gondor Food Processing Machinery., главным образом благодаря нашим превосходным технологиям и высококачественному сервису в области оборудования для пищевой промышленности..

Подтвердите решение: Автоматическая линия по производству колбас в Венесуэле

В марте, клиенты отправляли запросы онлайн для связи. В связи с четкими механическими требованиями заказчика, наш руководитель проекта и клиент очень хорошо общались, и он порекомендовал клиенту на выбор несколько автоматических линий по производству колбасных изделий., которые хорошо продаются на нашей фабрике.

Затем, они тщательно обсудили детали процесса от обработки сырья до наполнения колбасы, дымящийся, и упаковка. В процессе общения, мы ответили на различные вопросы клиентов и развеяли их опасения, который опирался на наш богатый отраслевой опыт и профессиональные знания о различных оборудование для пищевой промышленности.

Достижение сотрудничества на линии по производству колбас

Благодаря многочисленным онлайн-встречам и детальной демонстрации наших решений, наши клиенты высоко оценили наши решения и услуги. Кроме того, самое современное оборудование и технологии, предоставленные Фабрикой Гондора, могут обеспечить гигиену., качество вкуса, и эффективная производственная мощность колбасного производства. После согласования и подтверждения всех деталей проекта, мы успешно подписали контракт с нашим клиентом из Венесуэлы на поставку индивидуальной автоматической линии по производству колбасных изделий..

Гондор организует производство и отгрузку

Машины Гондора тщательно отбирают все материалы для производства всех машин на нашем заводе.. Что еще более важно, контроль качества осуществляется на протяжении всего производственного процесса, чтобы гарантировать качество продукции. Завершено производство линии по производству колбасных изделий по индивидуальному заказу заказчика., и прошел проверку качества в июне. До сих пор, наш клиент в Венесуэле завершил приемку, и все вопросы были проверены и подтверждены. Линия по производству колбас готова к отправке!

Более того, Эта линия по производству колбас использует передовые системы автоматического управления., которые обеспечивают точный контроль производственного процесса, обеспечение высокой стабильности и постоянства качества каждой партии колбас. Кроме, мы также используем материалы (Пищевой класс 304 Нержавеющая сталь) которые легко чистить и дезинфицировать, обеспечение соответствия производимых колбасных изделий строгим гигиеническим нормам.

Доставка автоматической линии по производству колбас в Венесуэлу

Почему венесуэльский клиент выбирает Gondor Machinery?

В группе Гондора, мы стремимся предоставить различные оборудование для пищевой промышленности и упаковки с превосходным качеством и высокой эффективностью производства. На нашем заводе также внедрена передовая система управления производством, позволяющая гарантировать выполнение каждого заказа в кратчайшие сроки без ущерба для качества.. Поэтому, заказчик из Венесуэлы выбрал Гондор для повышения эффективности производства колбасных изделий. Вот некоторые моменты о продукции, которые произвели впечатление на клиентов.:

Различные сертификаты для техники Гондора – Производители пищевого оборудования

Проверка сырья

Чтобы гарантировать, что они соответствуют стандартам качества и правилам безопасности., Гондор проводит предварительную проверку качества всего поступающего сырья..

Обработка компонентов

После обработки каждого компонента линии по производству колбас, необходимо провести проверку размеров и характеристик, чтобы убедиться, что он соответствует проектным спецификациям..

Процесс сборки

Затем, собрать проверяемые компоненты в полноценные машины или модули оборудования.. В процессе, ключевые проверки могут гарантировать правильность и отсутствие ошибок на каждом этапе.

Полное машинное тестирование

Комплексное тестирование направлено на обеспечение правильной работы производственных линий в различных условиях.. И это включает в себя функциональное тестирование, испытания на долговечность, и тестирование безопасности.

Предпоставочный осмотр

Прежде чем покинуть нашу фабрику, мы обычно проводим заключительную комплексную проверку, чтобы убедиться, что все параметры и стандарты соответствуют требованиям клиентов и отрасли..

Прием клиентов

Перед доставкой, мы пригласим клиента на приемочные испытания, чтобы убедиться, что все приобретаемые машины полностью соответствуют его потребностям и ожиданиям..

Сотрудничество с Gondor Machinery над проектом линии по производству колбас

До официального запуска линии по производству колбас в Венесуэле, мы поможем нашим клиентам в отладке и опытной эксплуатации оборудования для обеспечения бесперебойной работы. Если вы хотите запустить собственную производственную линию, выбор Gondor Machinery — ваш идеальный выбор, и вы сможете насладиться эффективными производственными линиями, а также комплексным обслуживанием. Наш богатый производственный опыт и передовые технологии могут предоставить вам всестороннюю поддержку и оптимальные решения..