Gondor Die-Formed Hard Candy Production Line Introduction

If you are looking for an efficient and reliable solution, our hard candy automatic die forming production line is your ideal choice. As an advanced hard candy production line, it integrates vacuum cooking, automatic coloring/flavoring, and precision die formed candy production line technology to easily meet high-volume commercial demands.

Gondor Die-Formed Hard Candy Production Line Models

To meet the needs of different production scales, we offer various models of die-formed candy production lines. If you have any other requirements, please contact us and we will provide you with a free consultation and quotation.

| Модель | YT200 | YT400 | YT1000 |

| Емкость | 150кг/ч | 300кг/ч | 600-1000кг/ч |

| Candy Weight | As Per the Candy Size | ||

| Скорость внесения депозита | 500шт/мин | 1000шт/мин | 2000-4000шт/мин |

| Steam Requirement | 200кг/ч, 0.5-0.8МПа | 300кг/ч, 0.5-0.8МПа | 400-600кг/ч, 0.5-0.8МПа |

| Рабочее состояние | Temperature 20℃-25℃; Влажность<55% | ||

| Electric Power Needed | 3018kw/380v/50hz | 18kw/380v/50hz | 45-60kw/380v/50hz |

| Total Length | 16м | 12м | 60KW/380V/50HZ |

| Weight of Machine | 4500кг | 8000кг | 10000-15000кг |

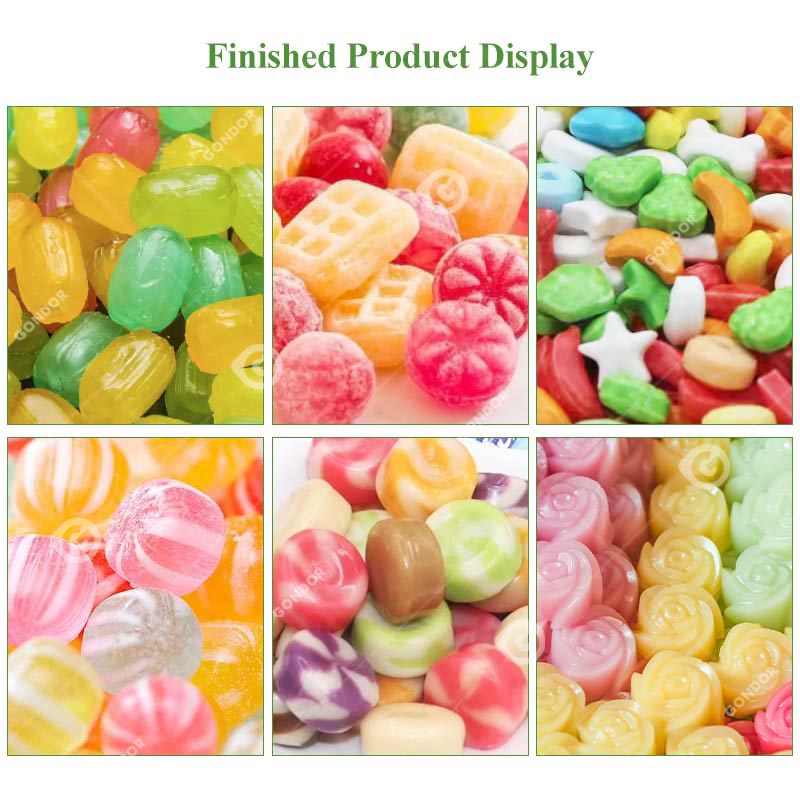

Industry Applications of Gondor Die-Formed Hard Candy Production Lines

The die-formed candy production line is a versatile solution used across various sectors. За пределами традиционных кондитерских изделий, it is increasingly utilized in health and pharmaceutical industries due to its precision and efficiency.

1. Traditional Confectionery Industry

This is the primary sector for hard candy making machines, focusing on mass-market consumer sweets:

- Fruit-Flavored Hard Candies: Single-color, double-color, or multi-color striped candies.

- Center-filled Candies: Using advanced die-formed hard candy production line technology to inject jam, шоколад, or powder into the candy core.

- Монетные дворы & Breath Fresheners: High-density mints that require the structural integrity provided by die-forming.

- Die-formed Lollipops: Specialized lines can automatically insert sticks during the forming process for spherical or 3D-shaped lollipops.

2. Nutritional Supplements Industry

Molded hard candy production lines are ideal for “functional candies” because they ensure precise weight and ingredient distribution:

- Throat Lozenges: Throat lozenges containing menthol and eucalyptus oil.

- Пищевые добавки: Candy-based products that make it easier for children and the elderly to ingest vitamins and minerals.

- Functional Ingredients: Hard candies fortified with probiotics, lutein or dietary fiber.

3. Пищевые ингредиенты & Industrial Processing

- Выпечка & Dessert Toppings: Producing specific shapes or crushed candy fragments for cake and ice cream decorations.

- Corporate Branding: Customized shapes or logo-embossed candies for hotels, airlines, and corporate gifts.

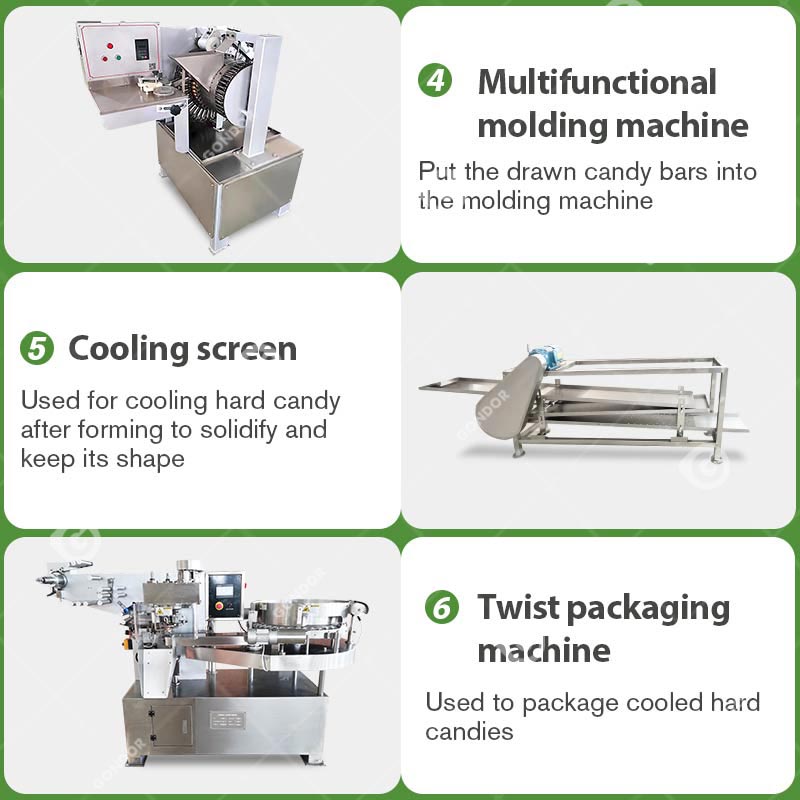

Molded Hard Candy Production Line Workflow

This production line achieves high automation from raw material processing to final packaging. The specific process is as follows:

Operators add water and ingredients to the jacketed cooking pot and heat them to a preset high temperature. Precise temperature control ensures the syrup reaches the ideal viscosity and moisture content.

The cooked candy mass is poured onto the cooling table for physical cooling. На этом этапе, operators fold the mass and evenly incorporate flavors, цвета, and other additives.

The pliable candy mass is placed into the batch roller to form a thick rope, which then automatically enters the rope sizer to be stretched into a consistent thin rope, ensuring uniform weight for each candy.

The thin rope enters the hard candy forming machine, where it is instantaneously cut and pressed into preset shapes by high-speed rotating dies, ensuring sharp contours and exquisite patterns.

Newly formed candies enter the cooling cabinet. Through circulating cold air, the candies are rapidly cooled and stabilized while tiny fragments are screened out.

The stabilized candies are fed into the twist packing machine, which automatically completes filling, twist-sealing, и резка. The finished products are then ready for storage.

Can this production line make lollipops?

Да, this production line can produce lollipops. By configuring a specialized машина для формирования леденцов within the line, it enables compatible production for both hard candies and lollipops. During the instantaneous die-forming process, the equipment automatically synchronizes the “stick-insertion” step, accurately planting plastic or paper sticks into the center of the candy mass. Whether it is a classic spherical shape, a flat disc, or complex 3D shapes, the die-forming process ensures precise contours and secure sealing. Этот “multi-purpose” capability not only increases product variety but also provides customers with great flexibility to switch between the hard candy and lollipop markets.

Gondor Die-Formed Hard Candy Production Line Features

- Высокая автоматизация & Кастомизация: Fully automated process from cooking and rope sizing to forming. We support customer customization for specific candy shapes, размеры, and factory layouts.

- Precision Engineering: Utilizes a jacketed cooking pot for vacuum cooking and a high-speed lollipop forming machine to ensure dense texture and exquisite candy appearance.

- Integrated Packaging Solution: Includes a complete twist packing system and sorting solution, enabling a seamless transition from production to retail-ready packaging.

- Global After-Sales Guarantee: One-year warranty with triple pre-shipment inspections. We provide multi-language instructional videos, UPS spare parts delivery, and on-site overseas engineer support.

- Seamless Logistics: Even without customs experience, we offer reliable door-to-door shipping via sea, воздух, or express to ensure a worry-free purchase.