Gondor Pita-Brotmaschine

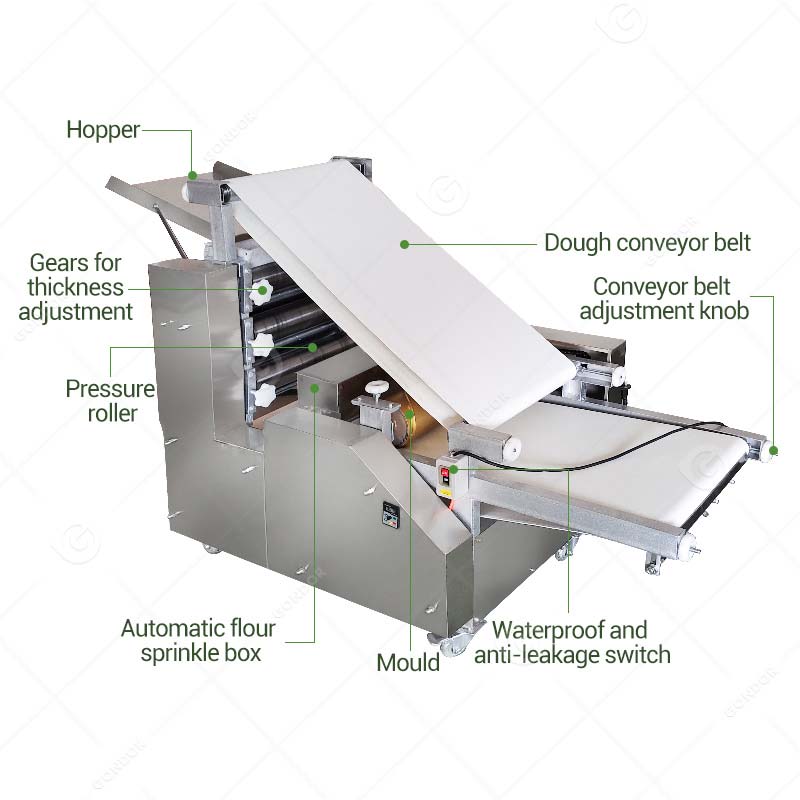

Kommerzielle Pita-Brotmaschine kann zur Herstellung verschiedenster Teige verwendet werden, wie Tortillas, Fladenbrot, Chapatti, Arabisches Brot, usw. Darüber hinaus, Diese Pita-Maschine ist mit einer hochfesten Teigpresswalze ausgestattet, um den Teig glatt und dehnbar zu machen, mit gleichmäßiger Dicke, während die automatische Puderfunktion ein Ankleben des Teigs verhindert.

Zusätzlich, Die Pita-Brotbackmaschine kann auch die Dicke und Produktionsgeschwindigkeit des Teigs je nach Bedarf anpassen, und unterstützt individuelle Teige in verschiedenen Formen und Größen.

Die Kernfunktion der Pita-Brotmaschine besteht darin, den Teig bei hohen Temperaturen schnell aufzublähen, eine Mulde bilden “Tasche,” welches dann direkt verzehrt werden kann, in Scheiben geschnitten, oder nach dem Abkühlen als Füllung verwenden.

Spezifikationen der Pita-Brotbackmaschine

| Modell | Größe | Gewicht | Ausgabe | Leistung | Durchmesser der Knödelhaut |

| GD-160 | 1250*450*1050mm | 180kg |

3000 Stk/h Kann angepasst und angepasst werden |

2.2kw | D 7-50 cm |

Hauptnachfragebereiche für kommerzielle Gondor-Pita-Brotmaschinen

Restaurants im Nahen Osten, Fastfood-Restaurants, Streetfood-Stände, usw. Fladenbrot ist eine häufige Lebensmittelzutat. Diese Ausrüstung kann schnell eine große Menge Fladenbrot produzieren, um die große Nachfrage zu Spitzenzeiten zu decken.

Produktion von Pita-Brot in großem Maßstab, um den Groß- und Einzelhandelsbedarf des Marktes zu decken. Diese Maschine kann die Produktionseffizienz verbessern, Arbeitskosten senken, und stellen die Qualitäts- und Hygienestandards von Brot sicher.

Im Buffetrestaurant des Hotels, Frühstücksservice und andere Szenarien, Pita-Brotbackmaschinen werden benötigt, um den Gästen frisches und köstliches Pita-Brot zu bieten, das den unterschiedlichen Geschmacksbedürfnissen der Gäste gerecht wird.

Bäckereien bieten spezielles Fladenbrot an. Der Einsatz von Pita-Brotmaschinen kann Bäckereien dabei helfen, ihr Produktsortiment zu erweitern, mehr Kunden anziehen, und die Wettbewerbsfähigkeit des Geschäfts steigern.

Für einige Familien, die sich gesund ernähren, Bei diesem Gerät handelt es sich um ein praktisches Küchengerät. Benutzer können frisch zubereiten, Zutatfreies Fladenbrot zu Hause ganz nach eigenem Geschmack und Bedarf zubereiten und den Spaß am Backen genießen.

Es müssen Verpflegungsdienste für eine große Anzahl von Studenten und Mitarbeitern bereitgestellt werden. Die Backmaschine kann der Kantine dabei helfen, schnell genug Pita-Brot zuzubereiten, um den Bedarf der Lehrer zu decken, Studenten und Mitarbeiter.

Hauptvorteile der Gondor Pita-Brotmaschine

- Mit vollautomatischer Betriebsfunktion, es spart erheblich Arbeit, ist einfach und effizient zu bedienen, und verbessert die Produktionseffizienz.Vollautomatisch

- Ausgestattet mit einem fortschrittlichen automatischen Pudersystem, um ein Anhaften des Teigs zu verhindern, sorgen für einen reibungslosen Produktionsablauf, Vermeiden Sie Verschwendung und Betriebsverzögerungen.Automatisches Pulverisieren

- Die Maschine verfügt über Geschwindigkeits- und Dickenanpassungsfunktionen, die Benutzer entsprechend ihren spezifischen Bedürfnissen anpassen können, die Produktion flexibler gestalten.Einstellbare Parameter

- Komplett aus Edelstahl gefertigt, es ist wasserdicht und rostfrei, Gewährleistung von Haltbarkeit und einfacher Reinigung im Langzeitgebrauch.Strapazierfähiges Material

- Verwenden Sie eine hochfeste Teigpresswalze, um einen glatten und duktilen Teig zu gewährleisten, gleichmäßige Dicke und stabile Qualität.Hochfestes Teigpressen

- Schnelle Produktionsgeschwindigkeit, produzieren können 60 Zu 120 Pfannkuchen pro Minute, Erfüllung der Anforderungen der Großserienproduktion.Hochgeschwindigkeitsproduktion

- Teige unterschiedlicher Form und Größe können je nach Benutzerbedarf individuell angepasst werden, um unterschiedlichen Produktanforderungen gerecht zu werden.Vielfältige Individualisierung

Arbeitsablauf einer kommerziellen Pitta-Brotbackmaschine

Gondor Kommerzielle Pita-Brotmaschine – Helfen Sie dabei, die Produktionskapazität einfach zu steigern

Wenn Sie nach einem Gerät suchen, das die Produktionseffizienz erheblich verbessern kann, Sparen Sie Arbeitskosten und stellen Sie eine gleichbleibende Produktqualität sicher, Die Pita-Maschine von Gondor ist Ihre ideale Wahl! Mit hochfesten Teigwalzen, automatisches Pudersystem und flexible Dickenanpassungsfunktion, Diese Maschine kann produzieren 3000-6000 Pitabrote pro Stunde, um den Anforderungen der Großproduktion gerecht zu werden. Unsere Ausrüstung bietet Ihnen ein stabiles und qualitativ hochwertiges Pita-Brotbackerlebnis, Wir helfen Ihrem Unternehmen auf ein höheres Niveau. Bestellen Sie jetzt und machen Sie sich auf den Weg zum Erfolg!