Einführung in die Produktionslinie für gestanzte Hartbonbons in Gondor

Wenn Sie nach einer effizienten und zuverlässigen Lösung suchen, Unsere automatische Produktionslinie zum Formen von Hartbonbons ist Ihre ideale Wahl. Als fortschrittliche Produktionslinie für Hartbonbons, Es integriert Vakuumgaren, Automatische Färbung/Aromatisierung, und präzisionsgestanzte Süßwarenproduktionslinientechnologie, um den kommerziellen Anforderungen großer Mengen problemlos gerecht zu werden.

Gondor-Modelle für gestanzte Hartbonbon-Produktionslinien

Um den Anforderungen verschiedener Produktionsmaßstäbe gerecht zu werden, Wir bieten verschiedene Modelle von Produktionslinien für geformte Süßigkeiten an. Wenn Sie weitere Anforderungen haben, Bitte kontaktieren Sie uns und wir erstellen Ihnen eine kostenlose Beratung und ein Angebot.

| Modell | YT200 | YT400 | YT1000 |

| Kapazität | 150kg/h | 300kg/h | 600-1000kg/h |

| Süßigkeitengewicht | Gemäß der Bonbongröße | ||

| Einzahlungsgeschwindigkeit | 500Stk./Min | 1000Stk./Min | 2000-4000Stk./Min |

| Dampfbedarf | 200kg/h, 0.5-0.8mpa | 300kg/h, 0.5-0.8mpa | 400-600kg/h, 0.5-0.8mpa |

| Arbeitszustand | Temperatur 20℃-25℃; Luftfeuchtigkeit<55% | ||

| Elektrischer Strom erforderlich | 3018kW/380 V/50 Hz | 18kW/380 V/50 Hz | 45-60kW/380 V/50 Hz |

| Gesamtlänge | 16M | 12M | 60KW/380V/50HZ |

| Gewicht der Maschine | 4500kg | 8000kg | 10000-15000kg |

Industrieanwendungen der Gondor-Produktionslinien für geformte Hartbonbons

Die Produktionslinie für gestanzte Bonbons ist eine vielseitige Lösung, die in verschiedenen Branchen eingesetzt wird. Jenseits traditioneller Süßwaren, Aufgrund seiner Präzision und Effizienz wird es zunehmend in der Gesundheits- und Pharmaindustrie eingesetzt.

1. Traditionelle Süßwarenindustrie

Dies ist der Hauptsektor für Maschinen zur Herstellung von Bonbons, Der Schwerpunkt liegt auf Konsumsüßwaren für den Massenmarkt:

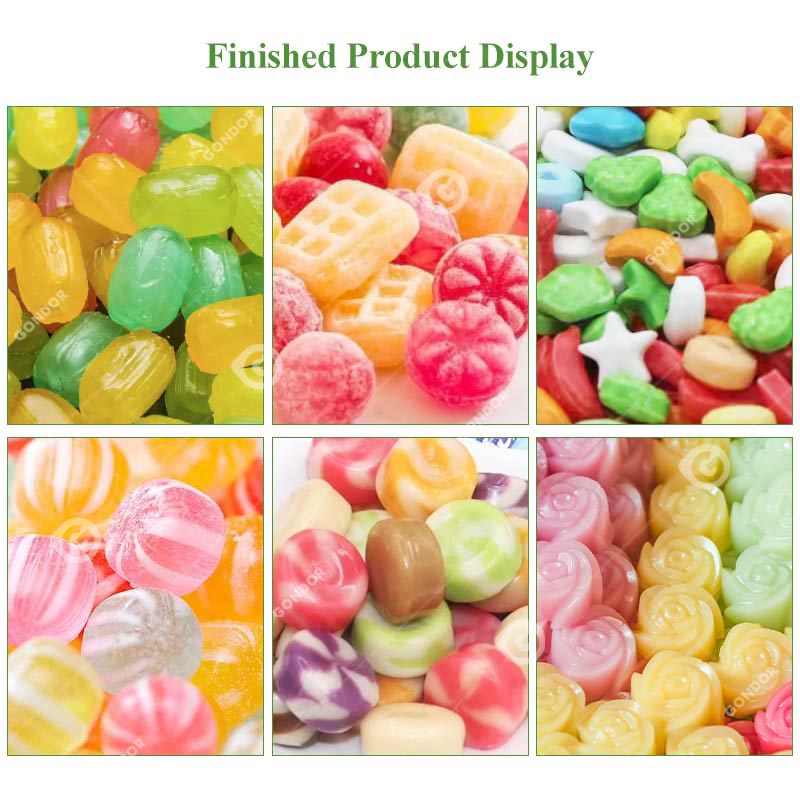

- Hartbonbons mit Fruchtgeschmack: Einfarbig, zweifarbig, oder mehrfarbig gestreifte Bonbons.

- Mittig gefüllte Bonbons: Einsatz fortschrittlicher, stanzgeformter Hartbonbon-Produktionslinientechnologie zum Einspritzen von Marmelade, Schokolade, oder in den Bonbonkern pulverisieren.

- Pfefferminzbonbons & Atemerfrischer: Prägestätten mit hoher Dichte, die die strukturelle Integrität erfordern, die durch das Formen entsteht.

- Gestanzte Lutscher: Spezielle Linien können während des Formungsprozesses automatisch Stäbchen für kugelförmige oder 3D-förmige Lutscher einführen.

2. Industrie für Nahrungsergänzungsmittel

Produktionslinien für geformte Hartbonbons sind ideal für “funktionelle Bonbons” denn sie sorgen für eine präzise Gewichts- und Zutatenverteilung:

- Halspastillen: Halspastillen mit Menthol und Eukalyptusöl.

- Nahrungsergänzungsmittel: Produkte auf Bonbonbasis, die Kindern und älteren Menschen die Aufnahme von Vitaminen und Mineralstoffen erleichtern.

- Funktionelle Inhaltsstoffe: Mit Probiotika angereicherte Hartbonbons, Lutein oder Ballaststoffe.

3. Lebensmittelzutaten & Industrielle Verarbeitung

- Backen & Dessert-Toppings: Herstellung spezifischer Formen oder zerkleinerter Bonbonfragmente für Kuchen- und Eisdekorationen.

- Unternehmensbranding: Kundenspezifische Formen oder Bonbons mit Logoprägung für Hotels, Fluggesellschaften, und Firmengeschenke.

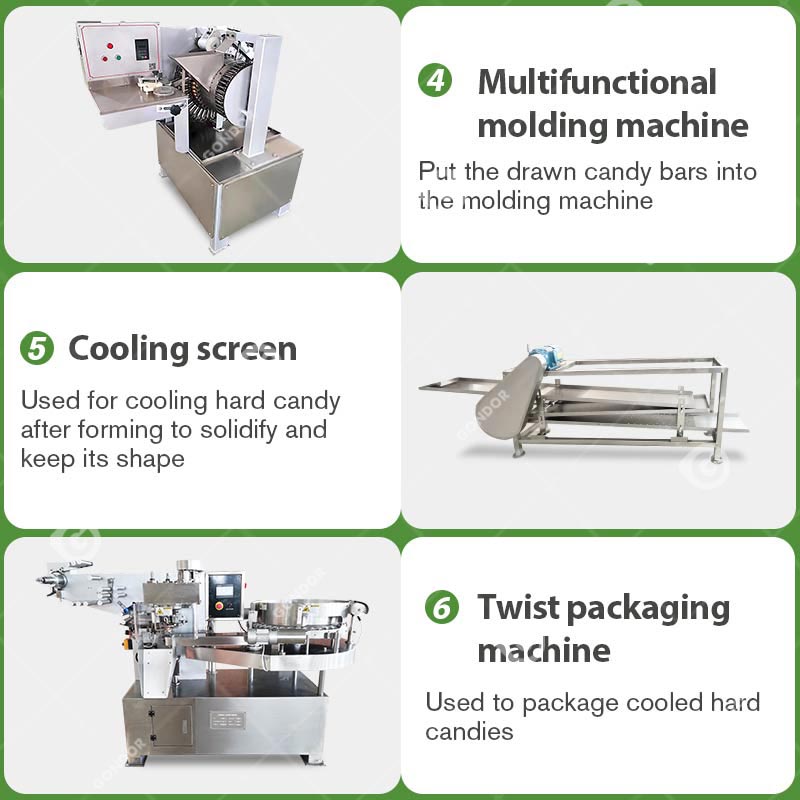

Arbeitsablauf in der Produktionslinie für geformte Hartbonbons

Diese Produktionslinie erreicht eine hohe Automatisierung von der Rohstoffverarbeitung bis zur Endverpackung. Der spezifische Prozess ist wie folgt:

Die Bediener fügen Wasser und Zutaten hinzu ummantelter Kochtopf und erhitzen Sie sie auf eine voreingestellte hohe Temperatur. Eine präzise Temperaturkontrolle stellt sicher, dass der Sirup die ideale Viskosität und den idealen Feuchtigkeitsgehalt erreicht.

Die gekochte Bonbonmasse wird zur physikalischen Kühlung auf den Kühltisch gegossen. Während dieser Phase, Die Bediener falten die Masse und fügen die Aromen gleichmäßig hinzu, Farben, und andere Zusatzstoffe.

Die biegsame Bonbonmasse wird in die Chargenwalze gegeben, so dass ein dicker Strang entsteht, das dann automatisch in den Seilmesser gelangt, um zu einem gleichbleibend dünnen Seil gedehnt zu werden, Gewährleistung eines einheitlichen Gewichts für jede Süßigkeit.

Das dünne Seil gelangt in die Bonbonformmaschine, Dort wird es sofort geschnitten und durch schnell rotierende Matrizen in voreingestellte Formen gepresst, sorgt für scharfe Konturen und exquisite Muster.

Neu geformte Bonbons gelangen in den Kühlschrank. Durch zirkulierende Kaltluft, Die Bonbons werden schnell abgekühlt und stabilisiert, während winzige Bruchstücke herausgesiebt werden.

Die stabilisierten Bonbons werden der Drehverpackungsmaschine zugeführt, wodurch das Befüllen automatisch abgeschlossen wird, Drehverschluss, und schneiden. Die fertigen Produkte stehen dann zur Lagerung bereit.

Kann diese Produktionslinie Lutscher herstellen??

Ja, Diese Produktionslinie kann Lutscher produzieren. Durch die Konfiguration eines spezialisierten Lutscherformmaschine innerhalb der Linie, Es ermöglicht eine kompatible Produktion sowohl für Hartbonbons als auch für Lutscher. Während des sofortigen Formgebungsprozesses, Das Gerät synchronisiert die automatisch “Stock-Einfügung” Schritt, Setzen Sie Plastik- oder Papierstäbchen präzise in die Mitte der Bonbonmasse ein. Sei es eine klassische Kugelform, eine flache Scheibe, oder komplexe 3D-Formen, Das Stanzverfahren sorgt für präzise Konturen und eine sichere Abdichtung. Das “Mehrzweck” Diese Fähigkeit erhöht nicht nur die Produktvielfalt, sondern bietet Kunden auch große Flexibilität beim Wechsel zwischen den Märkten für Bonbons und Lutscher.

Merkmale der Gondor-Produktionslinie für gestanzte Hartbonbons

- Hohe Automatisierung & Anpassung: Vollautomatischer Prozess vom Kochen über die Seildimensionierung bis zur Formung. Wir unterstützen Kundenanpassungen für bestimmte Bonbonformen, Größen, und Fabriklayouts.

- Präzisionstechnik: Verwendet einen ummantelten Kochtopf zum Vakuumgaren und eine Hochgeschwindigkeitsmaschine zum Formen von Lutschern, um eine dichte Textur und ein exquisites Bonbon-Aussehen zu gewährleisten.

- Integrierte Verpackungslösung: Beinhaltet ein komplettes Twist-Packsystem und eine Sortierlösung, Dies ermöglicht einen nahtlosen Übergang von der Produktion zur handelsfertigen Verpackung.

- Globale After-Sales-Garantie: Ein Jahr Garantie mit dreifacher Inspektion vor dem Versand. Wir stellen mehrsprachige Lehrvideos zur Verfügung, UPS-Ersatzteillieferung, und Unterstützung durch Ingenieure im Ausland vor Ort.

- Nahtlose Logistik: Auch ohne Zollerfahrung, Wir bieten einen zuverlässigen Haus-zu-Haus-Versand über den Seeweg an, Luft, oder Express, um einen sorgenfreien Kauf zu gewährleisten.