Gondor Einwegschüssel-Herstellungsmaschine

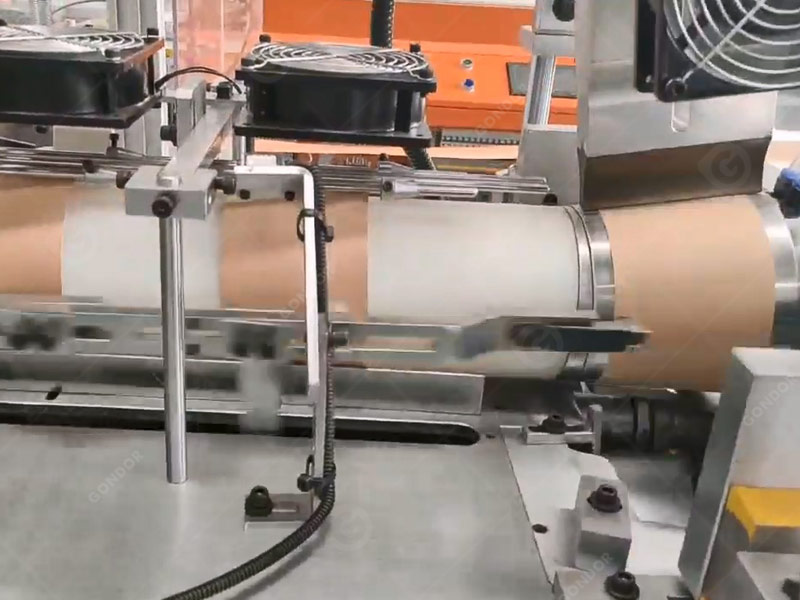

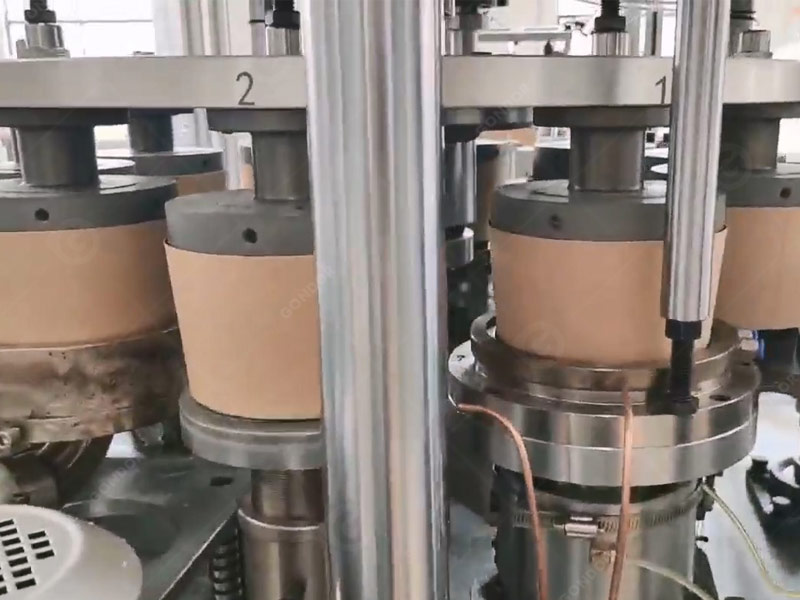

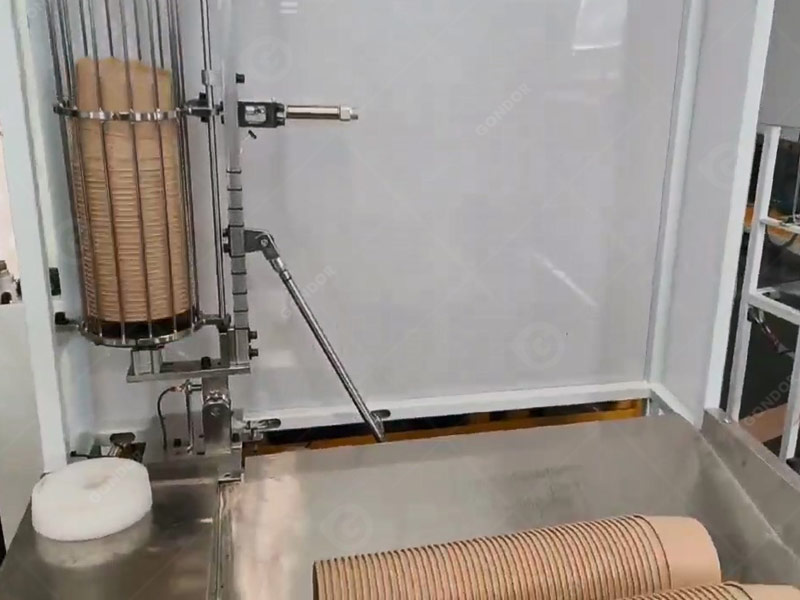

Maschine zur Herstellung von Einweg-Papierschalen ist eine Art Ausrüstung, die speziell für die Herstellung von Papierschalen verwendet wird. Es besteht hauptsächlich aus einem Papiereinzugsmechanismus, Formungsmechanismus, Heizgerät, Dichtungsmechanismus und Steuersystem. Das Funktionsprinzip der Papierschüsselmaschine besteht darin, das Papier dem Formmechanismus zuzuführen, und durch die Einwirkung von Hitze und Schimmel, Das Papier wird in die Form einer Papierschale geformt, und dann versiegelt. Darüber hinaus, Die Gondor-Papierschüsselherstellungsmaschine zeichnet sich durch hohe Effizienz und stabile Leistung aus, Außerdem können Parameter angepasst werden, um Papierschalen mit unterschiedlichen Spezifikationen und Formen herzustellen. Zusätzlich, Die Ausrüstung verfügt über einen hohen Automatisierungsgrad, einfache Bedienung, und breite anwendung, Dies bietet eine starke Unterstützung bei der Deckung der Marktnachfrage nach Papierschalen.

| Name | Maschine zur Herstellung von Papierschalen | |

| Modell | GD-D800 | GD-T185 |

| Leistung | 12kw | 15kw |

| Maximale Größe der Papierschüssel | 1400ml | 1500ml |

| Arbeitsluftquelle | 0.6-0.8Mpa; 0.4m³ | 0.5-0.8Mpa; 0.6m³ |

| Anforderungen an Papiermaterialien | Einfach und doppelt laminiertes Papier | |

| Ausgabe | 60-70 Stk./Min | 40-60Stk./Min |

| Papiergewicht | 200-330g/m²;±20g/m² | 240-340g/m²;±20g/m² |

| Schüsselgröße | Unten:80-125mm,Spitze:100-148mm; Höhe: 125mm. |

Unten:125-165mm,Spitze:150-185mm; Höhe: 45-80mm. |

| Größe | 2350*1320*1900mm | 2150*1320*1900mm |

| Gewicht | 3000kg | 2800kg |

| Becherseitige Abdichtung | Ultraschall | |

| Rändelung unten | HEISSLUFTSYSTEM | |

Anwendungsmarktumfang der Gondor-Papierschalenherstellungsmaschine

Bieten Sie maßgeschneiderte Dienstleistungen zur Herstellung von Papierschalen für Convenience-Food-Unternehmen an, um den unterschiedlichen Anforderungen der Unternehmen gerecht zu werden, Darüber hinaus stellen wir die Qualität von Fertiggerichten während des Transports und der Lagerung sicher.

Gefrorene Lebensmittel wie Eis, tiefgefrorene Knödel, usw. kann auch in Papierschalen verpackt werden. Die von der Papierschüsselmaschine hergestellten Papierschalen halten Umgebungen mit niedrigen Temperaturen stand und brechen oder verformen sich nicht.

Die Ausstellung bietet Verpflegung für Aussteller und Besucher. Papierschalen sind praktisch und hygienisch und können den Anforderungen der Ausstellung gerecht werden. Als Werbefunktion können individuell gestaltete Papierschalen mit dem Logo und Informationen zur Ausstellung bedruckt werden.

Es kann zur Aufbewahrung von Reis verwendet werden, Nudeln, Snacks und andere Lebensmittel, um die große Nachfrage von Fastfood-Restaurants zu decken. Das Markenlogo und Werbeinformationen des Fast-Food-Restaurants können ebenfalls gedruckt werden, um es zu bewerben.

Zur Aufbewahrung von Wontons werden üblicherweise Papierschalen verwendet, Knödel, usw., die bequem und hygienisch sind, Geeignet für die Geschäftseigenschaften von Snackbars, und kann auch die Verpackungsanforderungen verschiedener Snacks erfüllen.

Verwenden Sie Papierschalen zum Verpacken von Lebensmitteln, um die Sicherheit und Hygiene der Lebensmittel während der Lieferung zu gewährleisten. Darüber hinaus, Maßgeschneiderte Papierschalen können die Markenbekanntheit von Take-Away-Händlern steigern und mehr Kunden anziehen.

Bei Outdoor-Aktivitäten wie Picknicks und Camping, Umweltfreundliche Papierschalen sind nicht nur leicht und einfach zu transportieren, geeignet für Outdoor-Aktivitäten, sondern kann auch die Umweltverschmutzung verringern.

Erhebliche Wettbewerbsvorteile der Einwegschüsselherstellungsmaschine von Gondor Machinery

- Der Automatisierungsgrad ist extrem hoch. Der automatische Papiereinzug ist präzise, Die Heißsiegelung ist dicht, und jedes Glied arbeitet nahtlos zusammen, um die Produktion von Pappbechern effizient abzuschließen.Effiziente Integration

- >Es nimmt eine kleine Fläche ein und ist äußerst einfach zu bedienen. Eine Person kann es schaffen. Geringe Investitionen und geringes Risiko sind praktische Möglichkeiten, um die Kosten für Unternehmen zu senken.Bequem und praktisch

- Ersetzen Sie Formen, um Produkte mit unterschiedlichen Formen und Spezifikationen herzustellen, die unterschiedlichen Anforderungen gerecht werden und Unternehmen die Möglichkeit bieten, ihr Geschäft zu erweitern.Flexibel und wandelbar

- Der SPS-Bildschirm unterstützt mehrere Sprachen, kann mehrere Parametersätze speichern, und die manuelle Taste macht die Bedienung bequemer und verbessert die Arbeitseffizienz.Intelligent und einfach zu bedienen

- Der Becherkörper verfügt über eine Ultraschall-Heißversiegelung, das die Druckoberfläche nicht beschädigt und hocheffizient ist. Verbessern Sie das Erscheinungsbild des Produkts und steigern Sie die Wettbewerbsfähigkeit auf dem Markt.Hochwertige Verklebung

- Der Boden des Pappbechers wird nach dem Verkleben gerollt, Das ist gut und schön. Verbessern Sie die Produktqualität, Erhöhen Sie die Produktbekanntheit, und Verbraucher anlocken’ AufmerksamkeitFeine Rändelung

- Um Zeit und Aufwand zu sparen, gibt es ein automatisches Schmiersystem. Verbessern Sie die Effizienz, verlängern die Lebensdauer der Maschine, Wartungskosten reduzieren, und stellen die Kontinuität der Produktion sicher.Automatische Schmierung

- Bei den externen Leitplanken der Ausrüstung steht die Sicherheit an erster Stelle. Schützen Sie die persönliche Sicherheit, Unfallrisiken reduzieren, und bieten eine zuverlässige und sichere Umgebung für die Produktion.Sicherheitsgarantie

Intelligente Integrationslösungen für Produktionslinien

Um den Anforderungen einer großtechnischen und automatisierten Produktion gerecht zu werden, Wir bieten umfassende Integrationslösungen für Produktionslinien, die nahtlos mit den folgenden Geräten verbunden sind:

- Pappbechermaschine: Teilt Rohstoffe und Kontrollsysteme, Ermöglicht eine flexible Produktionsumstellung, um die Geräteauslastung zu steigern.

- Kissenverpackungsmaschine: Durch die direkte Integration wird eine Stapelung erreicht, Folienverpackung, und Verschließen von Papierschalen.

- Produktrückverfolgbarkeitssystem: Sprüht QR-Codes auf den Boden jeder Papierschale, Dies ermöglicht eine durchgängige Rückverfolgbarkeit der Qualität von der Produktion bis zum Verkauf.

Gondor Einweg-Papierschüssel-Herstellungsmaschine – Der Beginn einer neuen Reise zur effizienten Produktion

Unsere Maschine zur Herstellung von Einweg-Papierschalen bringt eine neue Revolution in Ihre Produktion. Es hat eine hervorragende Leistung, einfache Bedienung, und kann schnell und effizient hochwertige Papierschalen verschiedener Spezifikationen herstellen. Sei es die Gastronomie, Lebensmittelverarbeitung oder Take-Away-Bereich, es lässt sich perfekt anpassen. Und der präzise Formprozess gewährleistet die Stabilität und Zuverlässigkeit der Qualität der Papierschale. Wenn Sie sich für eine Papierschüsselmaschine von Gondor entscheiden, entscheiden Sie sich für Effizienz und Qualität. Lassen Sie uns gemeinsam an der Verbesserung der Produktionseffizienz arbeiten, Kosten senken, und einen breiteren Markt erschließen. Bestellen Sie es und beginnen Sie Ihren Weg zum Erfolg!