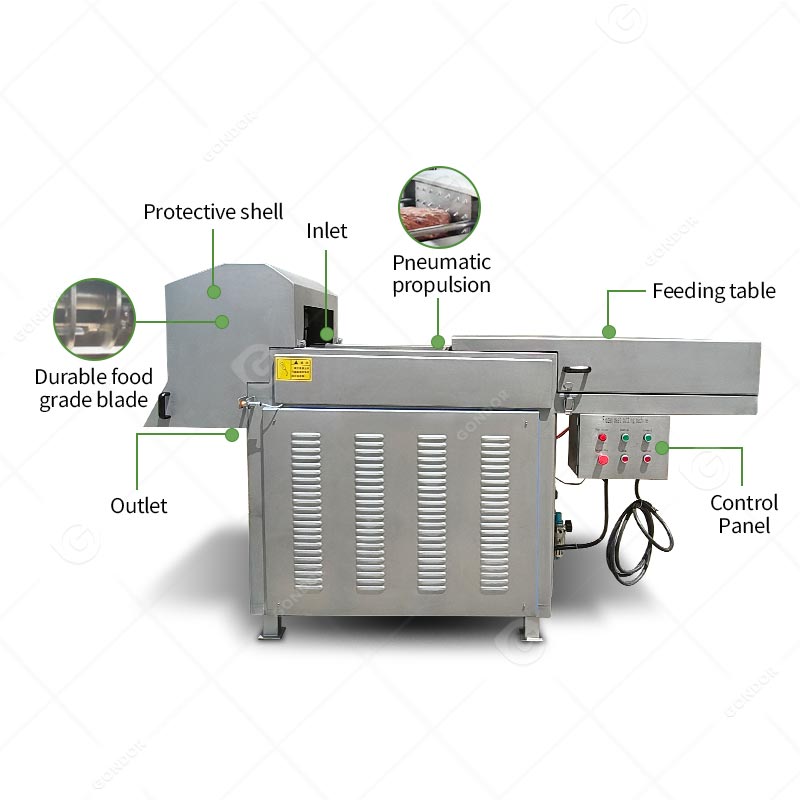

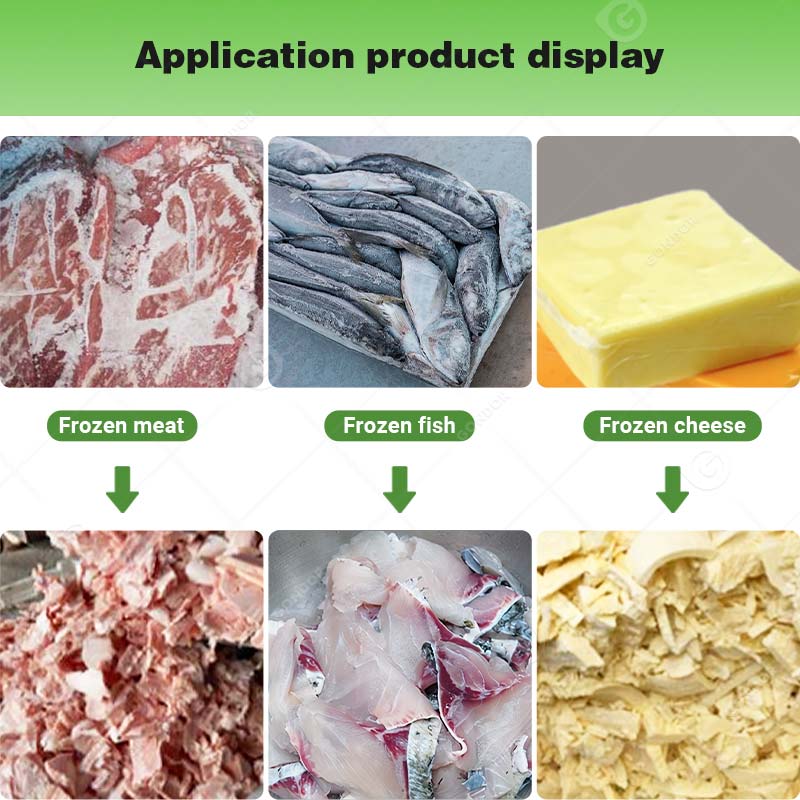

Brechmaschine für gefrorene Fleischblöcke ist eine Art Ausrüstung, die speziell für die Verarbeitung von gefrorenem Fleisch verwendet wird. Es besteht hauptsächlich aus einem Zufuhranschluss, Schneidwerkzeug, Übertragungssystem und Auslasshafen. Darüber hinaus, Die Maschine verfügt über einen hohen Wirkungsgrad und eine stabile Leistung, und kann gefrorenes Fleisch unterschiedlicher Härte verarbeiten. Es ist außerdem mit einer Schutzvorrichtung ausgestattet, Das ist sicher und zuverlässig. Zusätzlich, die Hackfleischpartikel sind gleichmäßig, die verschiedene Anforderungen der Lebensmittelverarbeitung erfüllen können, Verbessern Sie die Verarbeitungseffizienz von gefrorenem Fleisch erheblich, und sparen Zeit und Arbeitskosten für Lebensmittelverarbeitungsunternehmen.

GD-XMBB-B

GD-XMBB-S

| Modell | Leistung | Kapazität | Stromspannung | Größe | Motorgeschwindigkeit |

Suttergeschwindigkeit |

|

GD-XMBB-B |

11KW | 2000-3000KG/H | 380V | 2500*1070*1180MM | 960PN | 540PN |

|

GD-XMBB-S |

4KW | 600-1200KG/H | 380V | 1500*1000*1350MM | / |

/ |

Hauptzielmarkt für Gondor Meat Block Breaker

Wesentliche Funktionsmerkmale der Gondor-Maschine zum Brechen gefrorener Fleischblöcke

- Es kann mit einem Standard-Vorschubwagen ausgestattet werden, um Spritzer beim Schneiden zu verhindern, Halten Sie die Arbeitsumgebung sauber und ordentlich, und die Arbeitseffizienz verbessern.Spritzwassergeschütztes Schneiden

- Übernahme einer integralen Schweißkonstruktion, es ist stoßfest, geräuscharm, und stabil, Gewährleistung eines reibungslosen Maschinenbetriebs und Verbesserung der Produktionsqualität.Stabil und zuverlässig

- Ausgestattet mit einer automatischen Schutzvorrichtung, Es stoppt automatisch den Betrieb, wenn die vordere Abdeckung geöffnet wird, Das ist sicherer und schützt die Sicherheit des Bedieners.Sicherheitsgarantie

- Hergestellt aus 304 Edelstahlmaterial, robust und langlebig, mit starker Korrosionsbeständigkeit und langer Lebensdauer.Ausgezeichnetes Material

- Einfach zu bedienen und benutzerfreundlich, Es kann die Produktionseffizienz erheblich verbessern und die Arbeitsintensität verringern.Bequeme Bedienung

- Es gibt eine Rohfleisch-Betriebsplattform, Das ist praktisch und arbeitssparend, verbessert die Arbeitseffizienz, und entlastet die Arbeitnehmer.Arbeitssparend und effizient

- Der Maschinenschlitten ist außenliegend, wodurch die Rohstoffe nicht verschmutzt werden, Gewährleistung der Lebensmittelhygiene und -sicherheit, und ist leicht zu reinigen.Sauber und sicher

Inhalt erweitern

Zusätzlich zur effizienten Funktion, gefrorenes Fleisch aufzubrechen, Die moderne Lebensmittelverarbeitung erfordert oft detailliertere Rohstoffbehandlungssysteme. Zum Beispiel, Die gefrorener Fleischwolf und der Zerkleinerer für gefrorenes Fleisch kann eine Front-End-Verarbeitungslinie bilden: Der Fleischblockbrecher bricht zunächst große gefrorene Fleischstücke in kleine Stücke, die leicht zu handhaben sind, Anschließend zerkleinert der Fleischwolf sie je nach Produktanforderung zu Hackfleisch unterschiedlicher Dicke (wie Würstchen und Hackfleisch). Durch diese Kombination kann nicht nur der Einfluss des wiederholten Auftauens auf die Fleischqualität vermieden werden, sondern realisieren auch die integrierte Verarbeitung von ganzem gefrorenem Fleisch bis hin zu Standard-Hackfleisch, was den Automatisierungsgrad der Produktionslinie deutlich verbessert. Für Gerichte, die eine bestimmte Form benötigen (wie gebratenes Fleisch und Salatzutaten), Die Würfelschneidemaschine für gefrorenes Fleisch ist eine perfekte Ergänzung. Es kann gefrorenes Fleisch direkt in gleichmäßige Würfel schneiden, um sicherzustellen, dass die Produkte eine schöne Form haben und gleichmäßig erhitzt werden, Besonders geeignet für vorgekochte Gerichte, Fast-Food-Zentralküchen und andere Szenen, die eine hohe Standardisierung erfordern.

Häufige Fragen zum Tiefkühlfleischwolf

Gondor Zerkleinerer für gefrorenes Fleisch – Die Wahl für effiziente Verarbeitung

Wählen Sie die Zerkleinerungsmaschine für gefrorenes Fleisch von Gondor, um Ihre Reise zur effizienten Verarbeitung zu beginnen. Es kann gefrorenes Fleisch schnell in gleichmäßiges Hackfleisch schneiden, um den Anforderungen verschiedener Lebensmittelproduktionen gerecht zu werden. Es ist einfach zu bedienen, sicher und zuverlässig, Sie sparen Zeit und Arbeitskosten. Ob es sich um einen großen Lebensmittelverarbeitungsbetrieb handelt, ein Fleischwarenunternehmen, oder ein Ort zur Verarbeitung und zum Vertrieb von Halbfertigprodukten, Unser Tiefkühlfleischzerkleinerer ist Ihre rechte Hand. Kommen Sie und kaufen Sie es, um die Verarbeitung zu erleichtern!