Röhreneismaschine zu verkaufen

In der modernen Gastronomie und Kühlkettentransportbranche, Die Nachfrage nach Eiswürfeln steigt jährlich. Um der Marktnachfrage nach Effizienz gerecht zu werden, sauber, und schnelle Eisproduktion, Wir haben das ins Leben gerufen Eisröhrenmaschine—eine neue und innovative Eisherstellungsanlage, die für verschiedene kommerzielle Umgebungen entwickelt wurde. Ob es eine Bar ist, KTV, Milchteeladen, Wasserbar, Dessertladen, usw., Die Röhreneismaschine kann schnell liefern, wirtschaftlich, und essbare Eiswürfel, Fügen Sie Ihrem Unternehmen weitere Highlights hinzu.

Spezifikation der Maschine zur Herstellung von Eisröhren

|

Modell |

GL-T1 | GL-T2 | GL-T3 |

GL-T5 |

| Tägliche Ausgabe |

1000kg/Tag |

2000kg/Tag |

3000kg/Tag |

5000kg/Tag |

| Maschinendimension | 1570*915*2020mm | 1630*1010*2200mm | 1650*1535*14200mm | 1900*1100*2210mm |

| Gewicht | 600kg | 837kg | 1000kg | 1850kg |

| Eisdimension | 28mm | 28mm | 28mm | 28mm |

Gondor-Röhren-Eismaschine – Die notwendige Ausrüstung zur Eisherstellung für Gewerbeflächen

Röhreneismaschinen werden aufgrund ihrer effizienten und stabilen Eisproduktionsleistung häufig in verschiedenen gewerblichen Bereichen eingesetzt, um den Anforderungen verschiedener Branchen gerecht zu werden:

Hervorragende Leistungsvorteile der Röhren-Eismaschine

Röhren-Eismaschinen sind aufgrund ihrer effizienten und stabilen Eisherstellungsfähigkeiten ideal für alle Arten von gewerblichen Umgebungen. Im Folgenden sind die wichtigsten Leistungsvorteile aufgeführt:

Kühllösung für Eisröhrenmaschinen

Gondor-Maschinen Eisröhrenmaschinen sind effizient, schnell, und umweltfreundlich, Damit sind sie ideale Eisbereitungsgeräte für kleine Geschäfte und Ladenketten. Sie können hochwertige essbare Eiswürfel liefern, Effizienz verbessern, und Kosten sparen. Die Wahl einer Röhreneismaschine kann Ihr Unternehmen effizienter machen, sicher, umweltfreundlich,y und wettbewerbsfähig. Kontaktieren Sie uns jetzt, um mehr zu erfahren!

Häufig gestellte Fragen zur Röhreneismaschine

Q: Welche Vorteile hat Röhreneis gegenüber Scherbeneis und Blockeis??

A: Hohlzylinderrohre haben eine kleinere Kontaktfläche, ergebend 20% stärkere Schmelzbeständigkeit; einheitliche Größe, Dadurch entfällt die Notwendigkeit, Eis zu zerkleinern; transparent und ästhetisch ansprechend.

Q: Wie groß ist der Platzbedarf und der Energieverbrauch einer Röhreneismaschine mit einer Kapazität von 1 Tonne pro Tag??

A: Die integrierte Maschine ist ca 1.2 × 1.1 × 2.8 M (inklusive Eisspeicher), weniger belegen als 3 m²; Der Stromverbrauch pro Tonne Eis beträgt ca 45 kWh, sparen 25% im Vergleich zu einem Soletank.

Q: Kann es kontinuierlich betrieben werden? 24 Std.?

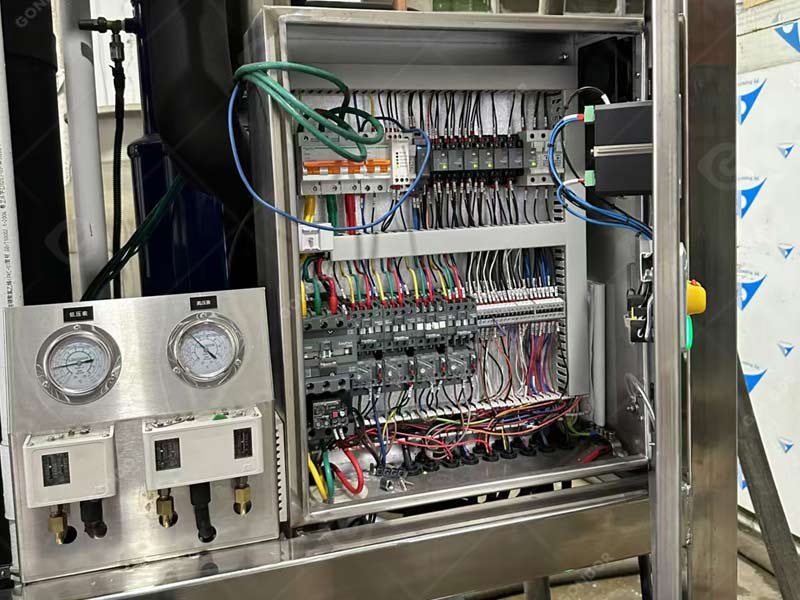

A: Ja, Die SPS überwacht automatisch die Eisdicke, Wasserstand, und Hochdruck, stoppt, wenn das Eis voll ist, und startet automatisch neu, wenn das Eis niedrig ist; Lediglich der Wasserpumpenfilter muss jedes Mal überprüft werden 8 Std..

Q: Was sind die Anforderungen an die Installationsumgebung für die Röhreneismaschine??

A: Umgebungstemperatur 5–35 ℃, gute Belüftung; ≥1,5 m Freiraum oben für Hebe- und Wartungsarbeiten; Stromversorgung 380 V/50 Hz, erfordern einen unabhängigen Leckageschutz und eine Erdung.

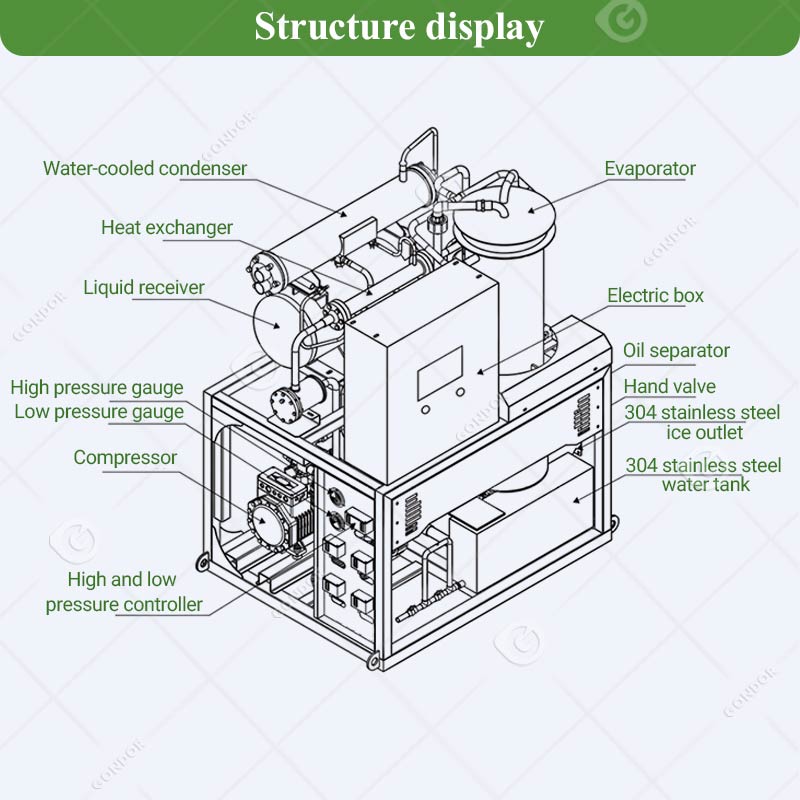

Mit seinem einzigartigen Design von “vertikales Mantelrohr + Wasserfilmspirale + Heißluftenteisung”, Der Röhreneisbereiter erreicht eine kontinuierliche Leistung, effiziente und energiesparende Herstellung von transparentem Röhreneis, Dies macht es zu einer idealen Lösung für die Eisherstellung im großen Maßstab für Branchen wie essbare Eisfabriken, Konservierung von Meeresfrüchten, und Betonkühlung.