Ausrüstung zur Extraktion ätherischer Öle von Gondor

Eine Maschine zur Extraktion ätherischer Öle ist ein effizientes und intelligentes Gerät zur Extraktion von Pflanzenessenzen, das darauf ausgelegt ist, das natürliche Aroma und die Wirkstoffe der Pflanzen weitestgehend zu erhalten. Dieses Gerät nutzt fortschrittliche Wasserdampfdestillationstechnologie, die die Temperatur genau steuern kann, so dass die aromatischen Bestandteile in den Pflanzenmaterialien schnell verdampft und zu Flüssigkeit kondensiert werden können, und die ätherischen Öle und Hydrolate können effizient abgetrennt werden.

Ob es sich um Laborforschung handelt, Kosmetikproduktion, der Lebensmittel- und Aromenindustrie, oder Verarbeitung von landwirtschaftlichen und pflanzlichen Essenzen, Dieses Gerät kann damit perfekt umgehen.

Spezifikation der industriellen Extraktionsmaschine für ätherische Öle

|

Kapazität

|

Leistung |

Größe |

Gewicht |

| 100L |

12kw |

1800*1000*2500mm |

500kg

|

|

200L

|

18kw |

2300*1000*2500mm |

700kg |

| 300L |

24kw |

2500*1000*3000mm |

1000kg

|

|

500L

|

36kw |

3000*2500*4500mm |

3000kg |

Anwendungsbranchen der Extraktionsmaschine für ätherische Öle

Kosmetika & HautpflegeindustrieEssen & GetränkeindustrieDuft & AromatherapieTraditionelle Medizin & Kräuterextraktion

Ätherische Öle sind wichtige Rohstoffe für hochwertige Hautpflegeprodukte, wie Lavendelöl und Rosenöl, die bei der Herstellung von Cremes verwendet werden, Essenzen, und Parfüme.

Viele ätherische Öle mit natürlichem Duft, wie ätherisches Zitronenöl und ätherisches Orangenöl, kann zum Würzen von Lebensmitteln und als Getränkezusatzstoffe verwendet werden.

Der Aromatherapie-Markt hat eine starke Nachfrage nach natürlichen ätherischen Ölen, wie Eukalyptus, Teebaum, Minze, usw., die im SPA weit verbreitet sind, Massage, Weihrauch und andere bereiche.

Ätherische Öle chinesischer Kräutermedizin wie Wermut, Engelwurz, und Adlerholz kann zur Verwendung in der Pharma- oder Gesundheitsproduktindustrie gewonnen werden.

Einzigartige Vorteile des industriellen Destilliergeräts für ätherische Öle

Präzise Temperaturregelung & Gleichmäßige Erwärmung

Durch den Einsatz von Thermoöl zur indirekten Erwärmung wird die Erwärmung gleichmäßiger und die Temperaturregelung präziser, Stellen Sie sicher, dass die ätherischen Ölbestandteile bei einer geeigneten Temperatur extrahiert werden, um zu verhindern, dass hohe Temperaturen ihre Wirkung zerstören.

Hervorragende Dichtungsleistung

Die ganze Maschine besteht aus 304 Edelstahl mit hochglanzpoliertem Design, um sicherzustellen, dass er schadstofffrei und leicht zu reinigen ist. Das Dichtungssystem ist optimiert, um Dampflecks zu vermeiden und die Extraktionseffizienz zu verbessern.

Effiziente Öl-Wasser-Trennung

Das Design des Plexiglas-Ölextraktionsbechers trennt ätherische Öle und Hydrolate präzise, um sicherzustellen, dass die Reinheit der ätherischen Öle die höchsten Standards erreicht, und der Trenneffekt übertrifft den herkömmlicher Geräte bei weitem.

Schnelle Kondensation & Effiziente Sammlung

Das Gerät ist mit einem optimierten Kondensationssystem ausgestattet, das Dampf schnell abkühlen kann, Verbessern Sie die Sammeleffizienz ätherischer Öle, den Produktionszyklus verkürzen, und die Gesamtproduktionskapazität erhöhen.

Vollautomatische intelligente Steuerung

Automatisches SPS-Steuerungssystem, Ein-Knopf-Bedienung, Echtzeitüberwachung der Temperatur, Druck und Flüssigkeitsstand, Vermeidung manueller Fehler und Verbesserung der Produktionsstabilität.

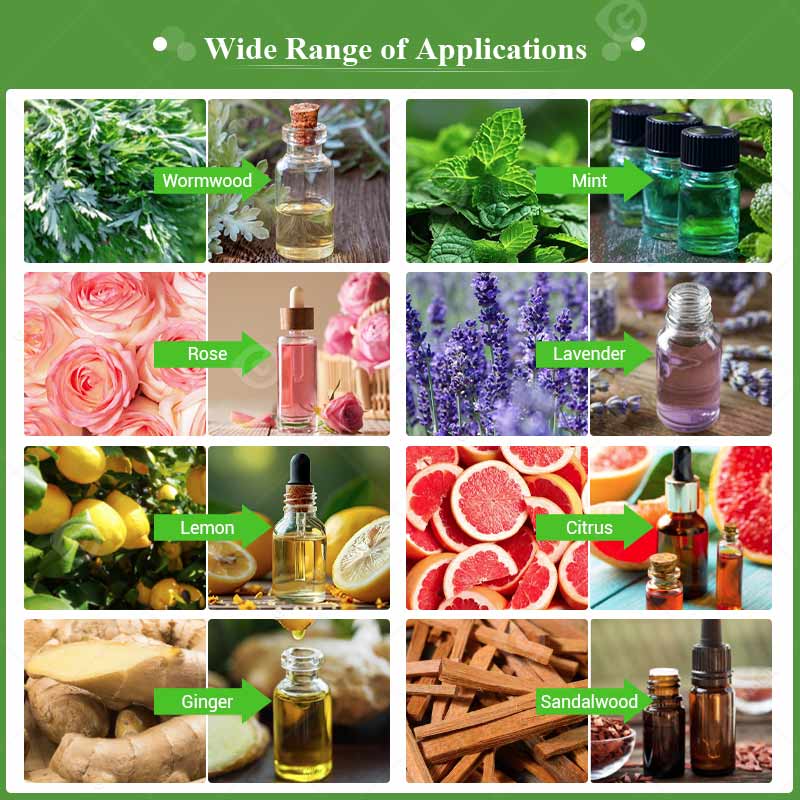

Breites Anwendungsspektrum

Anwendbar für die Extraktion ätherischer Öle aus verschiedenen Pflanzen wie Blumen, Blätter, Früchte, Rhizome, Samen, usw., mit starker Kompatibilität.

Arbeitsablauf der Destillationseinheit für ätherische Öle

Eine industrielle Destillationsanlage für ätherische Öle verwendet einen kontinuierlichen Prozess “externe Dampferzeugung + Destillationstank + Kondensator + Öl-Wasser-Trenner” um die flüchtigen Bestandteile pflanzlicher Materialien zusammen mit Wasserdampf zu destillieren.

Der Kessel erzeugt 0,4–0,7 MPa trockenen Sattdampf, Anschließend wird es durch einen Dampfverteiler druckstabilisiert und auf den Boden des Destillationstanks geleitet.

Dampf steigt durch ein poröses Verteilerrohr auf, gleichmäßiges Eindringen in die Rohmaterialschicht. Die ätherischen Öle in den Zellen bilden mit Wasser ein Azeotrop, welches bei abdestilliert wird 100 ± 5 ℃.

Der Öl-Wasser-Mischdampf gelangt in den Kondensator, Dort tauscht es im Gegenstrom Wärme mit Kühlwasser aus, Reduzierung der Kondensattemperatur auf 25–35 ℃.

Das Kondensat fließt in einen halbkugelförmigen Abscheider, wo es sich absetzt und in Schichten aufteilt. Die obere Schicht aus leichtem Öl läuft über in die Auffangflasche für ätherische Öle, während die untere Schwerölschicht intermittierend durch ein Ventil abgelassen wird.

Die wässrige Phase (Hydrosol) Es enthält Spuren ätherischen Öls und wird zur sekundären Destillation zurück an den oberen Rand des Destillationstanks gepumpt, Steigerung der Gesamtrendite um 3–5 %.

Schlackenaustrag und -beschickung

Nach der Destillation, Der schnell zu öffnende Bodendeckel wird geöffnet oder der Korb herausgehoben, und die Rohschlacke wird über einen Schneckenförderer zur Zuführ- oder Kompostierungssektion gefördert.

Entdecken Sie die reinsten aromatischen Schätze der Natur

Zusätzlich zu Destillations- und Extraktionsgeräten für ätherische Öle, wir bieten auch Blasenwaschmaschinen, automatische Abfüllmaschinen für Flüssigkeiten, und andere Ausrüstung, um den Pflanzenextraktionsbedarf verschiedener Unternehmen zu decken. Für weitere Informationen können Sie uns gerne kontaktieren! Kontaktieren Sie uns für ein Angebot oder technischen Support, Unser Team steht Ihnen jederzeit zur Verfügung!

Kontaktieren Sie uns jetzt