Maschine zur Herstellung von rotem Chilipulver

Industrielle Mahlmaschine für rotes Chilipulver ist eine effiziente und praktische Pulverisierungsausrüstung, das in der Pharmaindustrie weit verbreitet ist, Essen, chemische und andere Industrien. Dieses Gerät kann verschiedene Materialien fein pulverisieren, Besonders geeignet für trockene und spröde Materialien. Darüber hinaus, Die Feinheit der Materialpulverisierung kann durch die Öffnung des Siebs eingestellt werden. Zusätzlich, Die gesamte Maschine ist nach GMP-Standards ausgelegt, aus Edelstahl, mit einfacher Struktur, geringer Energieverbrauch und einfache Reinigung, welches derzeit die ideale Pulverisierungsausrüstung ist.

Spezifikation der industriellen Mahlmaschine für rotes Chilipulver

| Modell | Kapazität

(kg/h) |

Partikelgröße des Futters(mm) | Brechende Feinheit(Netz) | Motorleistung (kw) |

Spindelgeschwindigkeit (U/min) |

Dimension (mm) |

Gewicht (kg) |

| 15B | 20-150 | <10 | 20-120 | 2.2 | 6000 | 550*400*850 | 150 |

| 20B | 40-200 | <10 | 20-120 | 4 | 4500 | 600*550*1250 | 280 |

| 30B | 80-400 | < 12 | 20-120 | 7.5 | 3800 | 700*600*1450 | 340 |

| 40B | 100-800 | < 15 | 20-120 | 11 | 3400 | 900*800*1550 | 450 |

| 50B | 150-1000 | <18 | 20-120 | 15 | 3000 | 1050*850*1750 | 600 |

| 60B | 250-1500 | < 20 | 20-120 | 22 | 2800 | 1100*900*1880 | 900 |

| 80B | 350-2000 | < 25 | 20-120 | 30 | 2400 | 1200*950*2000 | 1250 |

| 100B | 500-3000 | < 28 | 20-120 | 37 | 2000 | 1350*1000*2100 | 1580 |

Nachfragebereiche für die industrielle Pulvermahlmaschine von Gondor

- Gewürze verarbeiten, Körner, usw. zu Pulver verarbeiten, Herstellung verschiedener Lebensmittel und Gewürze.Lebensmittelindustrie

- Zerkleinerung chemischer Rohstoffe für die anschließende Verarbeitung sowie Produktforschungs- und -entwicklungsexperimente.Chemische Industrie

- Futterverarbeitung und Zerkleinerung landwirtschaftlicher Nebenprodukte für die Tierzucht und Ressourcennutzung.Landwirtschaftliches Feld

- Wird zum Zerkleinern von Rohstoffen der chinesischen und westlichen Medizin verwendet, Unterstützung bei der Vorbereitungsverarbeitung, und Verbesserung der Arzneimittelwirksamkeit.Pharmazeutische Industrie

- Vorzerkleinerung von Erzen und Mahlen nichtmetallischer Mineralien für die Mineralverarbeitung, Schmelzen und Baustoffproduktion.Bergbaufeld

- Wird häufig in Labors von Universitäten und wissenschaftlichen Forschungseinrichtungen zur Unterstützung bei Materialforschung und Experimenten verwendet.Wissenschaftlicher Forschungsbereich

Erhebliche Wettbewerbsvorteile der Gondor-Chilipulver-Mahlmaschine

Mineralische Metalle, medizinische Körner, chemische Rohstoffe, usw. können alle verarbeitet werden, und die Produktformen sind vielfältig, Erfüllung der Anforderungen mehrerer Branchen.

Es hat einzigartige Vorteile, und seine Materialzerkleinerungsfeinheit kann je nach Sieböffnung flexibel angepasst werden, um unterschiedlichen Anforderungen gerecht zu werden.

Fortschrittliche Design- und Fertigungstechnologie sorgen für eine gleichmäßige Zerkleinerung, stabile Produktqualität, Hochwertige Materialien und eine gute Abdichtung sorgen dafür, dass die Verschmutzung durch Verunreinigungen sehr gering ist.

Ausgestattet mit intelligentem System, einfach und leicht zu bedienen, vernünftige Struktur, einfache Demontage und Montage verschiedener Komponenten, bequeme Wartung, Reduzierung von Ausfallzeiten und Verbesserung der Auslastung.

Hohe Zerkleinerungseffizienz, Verwendung von Hochgeschwindigkeitskomponenten zur schnellen Zerkleinerung von Materialien, und mehrere Modelle mit großer Verarbeitungskapazität, um eine hohe Effizienz bei der Produktion verschiedener Maßstäbe zu gewährleisten.

Einführung von Technologien und Materialien zur Geräuschreduzierung, Der Lärm ist gering, und es gibt ein effizientes Staubsammelsystem, um Umweltverschmutzung zu vermeiden und Umweltschutzanforderungen zu erfüllen.

Arbeitsablauf der Verarbeitungsmaschine für rotes Chilipulver

Rohstoffvorbehandlung

Magnetische Trennung → Entsteinen → Abbeeren und Säen → Grobzerkleinerung 3-5 mm Pfefferflocken.

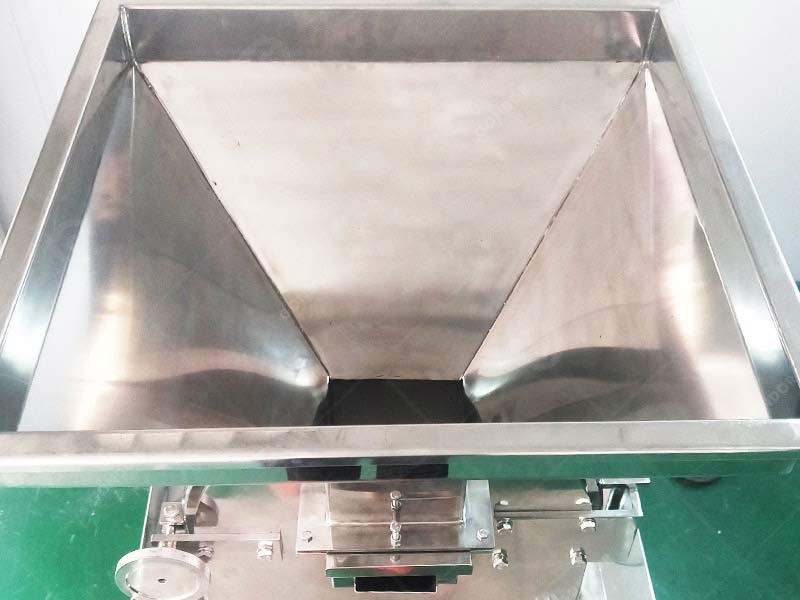

Quantitative Fütterung

Ein Schneckenförderer mit variabler Frequenz führt die Pfefferflocken gleichmäßig und mit einer festgelegten Geschwindigkeit in die Mühle ein (kg/h).

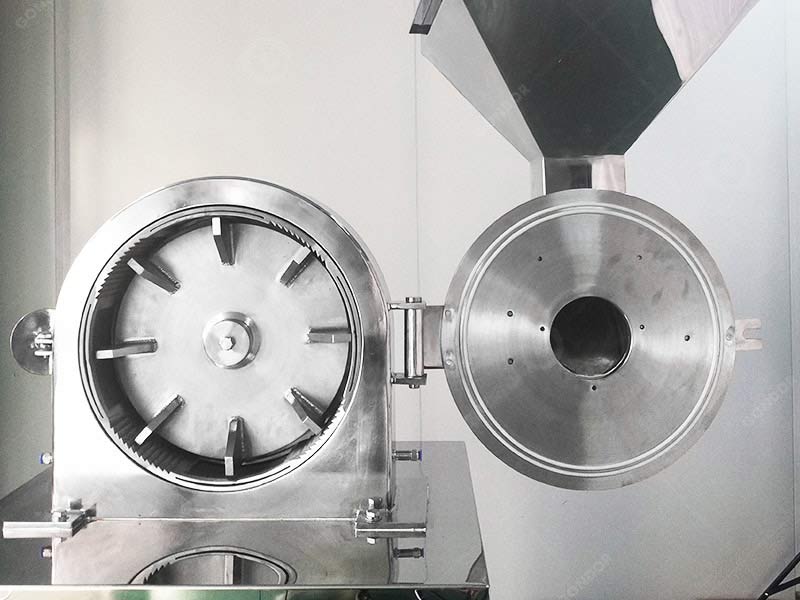

Schleifen bei niedriger Temperatur

Hochgeschwindigkeits-Hammermühlen schlagen und scheren das Pulver, während ein Axialventilator einführt 15-20 °C kalte Luft zur Ableitung der Reibungswärme.

Klassifizierung und Sammlung

Nach dem Schleifen, Das Pulver gelangt mit dem Luftstrom in einen Zyklonabscheider. 95% Ein Teil des Pulvers fällt in den versiegelten Trichter darunter; Der verbleibende staubbeladene Luftstrom wird ein zweites Mal durch einen Pulsbeutelfilter gefiltert, und das Abgas wird sauber abgeführt.

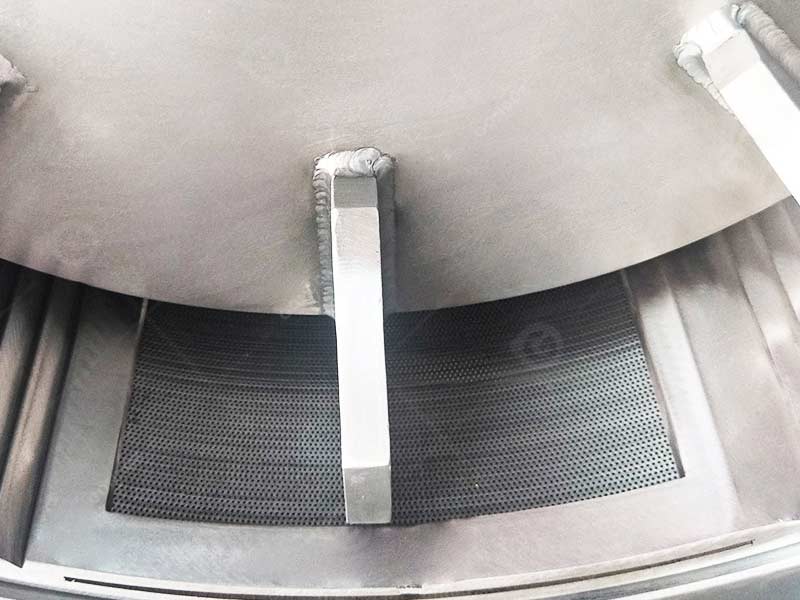

Sieben und erneut mahlen

Wenn eine feinere Partikelgröße erforderlich ist, Grobe Partikel werden nach dem Sieben über ein geschlossenes Rückführungssystem automatisch in die Mahlkammer zur Nachmahlung zurückgeführt.

Verpackung

Der untere Trichter ist mit einer Vakuumzuführung verbunden, um das fertige Pulver hineinzugeben 10-50 kg Alufolienbeutel bzw 200 L-Wendetrommeln, die dann mit Stickstoff gefüllt werden, versiegelt, und kühl gelagert, dunkler Ort.

Gondor Industrial Red Chili Pulvermahlmaschine – Experte für Mehrfeldschleifen

Wenn Sie auf der Suche nach einer hochwertigen Mühle sind, Dann ist unsere industrielle Pulvermühle die beste Wahl! Es hat eine breite Anwendbarkeit, hervorragende Leistung, zuverlässige Qualität, und einfache Bedienung! Unsere Maschine kann nicht nur Ihre vielfältigen Anforderungen erfüllen, sondern helfen Ihnen auch dabei, die Produktionseffizienz zu verbessern. Zögern Sie nicht, Bestellen Sie es jetzt, Und lassen Sie die industrielle Pulvermahlmaschine von Gondor Ihrem Unternehmen kraftvolle Impulse verleihen!