Der Industrieller Tunnelofen ist ein effizientes mechanisches Gerät, das durch Wärmeleitung ein gleichmäßiges Backen von Lebensmitteln erreicht, Konvektion und Strahlung. Es wird häufig in der Lebensmittelverarbeitung wie Brot verwendet, Gebäck, Kuchen, und Mondkuchen. Die Länge der Ausrüstung kann reichen 6-80 Meter, und es ist mit einem kontinuierlich arbeitenden Fördersystem ausgestattet, um eine stabile Backqualität zu gewährleisten. Darüber hinaus, Das wissenschaftliche Feuerrohrdesign und die verdickten Isoliermaterialien sparen erheblich Energie, und der einfach zu bedienende Mensch-Maschine-Touchscreen und importierte elektrische Komponenten sorgen für eine stabile Leistung. Es eignet sich für Lebensmittelunternehmen, die große Mengen an Lebensmitteln produzieren. Es kann die Leistung um erhöhen 2 Zeitaufwand und Reduzierung der Arbeitskosten. Mit seiner präzisen Temperaturregelung, gleichmäßiges Backen, und Haltbarkeit, Der Tunnelofen trägt dazu bei, die Lebensmittelproduktion effizient zu verbessern!

| Modell | Stromspannung | Länge jedes Ofens | Breite | Heizmethode | Mindestbestellmenge | Fließband |

| GD-10 | 380V | 2m/Abschnitt | 1m/1,4 m | Gas/Elektro | 10M | Einzelkette/Doppelkette |

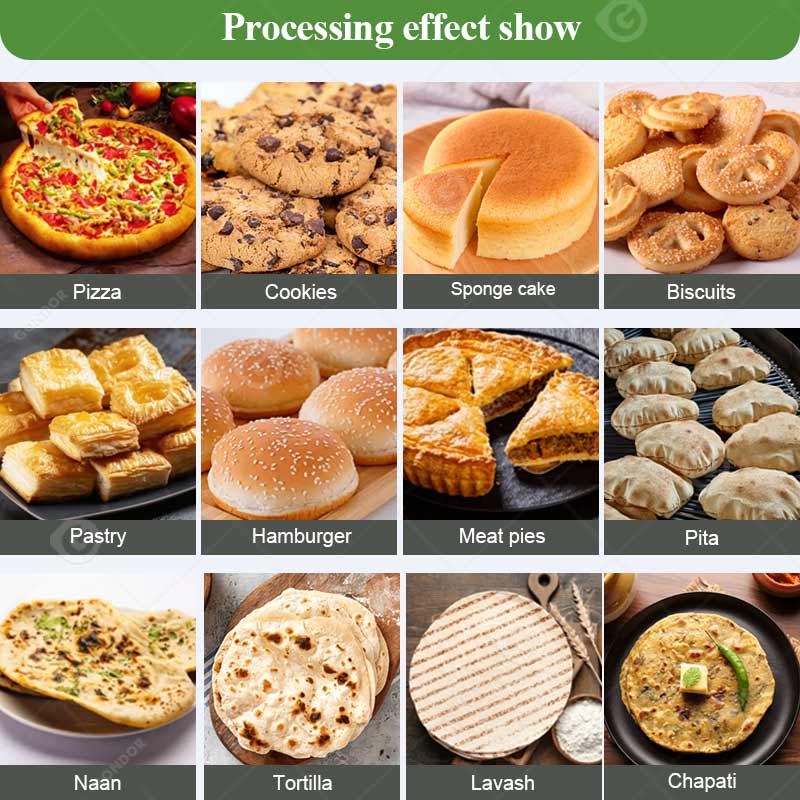

Der Gondor-Tunnelofen für Bäckereien ist weit verbreitet

Aufgrund seiner effizienten kontinuierlichen Produktionskapazität ist der Tunnelofen zu einem unverzichtbaren Gerät im Bereich der Lebensmittelverarbeitung geworden, gleichmäßiger Backeffekt, energiesparendes und umweltfreundliches Design und komfortable Bedienung.

Gilt für Grundbrot, zubereitetes Brot, Großbäckerei und Bäckereikette.

Weit verbreitet in Keksverarbeitungsbetrieben und industriellen Keksproduktionslinien.

Geeignet für die Massenproduktion von Kuchen, Eigelbkuchen, Mondkuchen und andere Backwaren.

Unterstützt kontinuierliches Backen chinesischer und westlicher Desserts.

Wird bei der Herstellung und Verarbeitung verschiedener Arten von Snacks verwendet.

Kernausrüstung für großformatige Backwaren.

Erfüllen Sie anspruchsvolle und hocheffiziente Backanforderungen.

Anwendbar für die Verarbeitung einiger gefrorener Teige und Fast-Food-Produkte, die vorgebacken werden müssen.

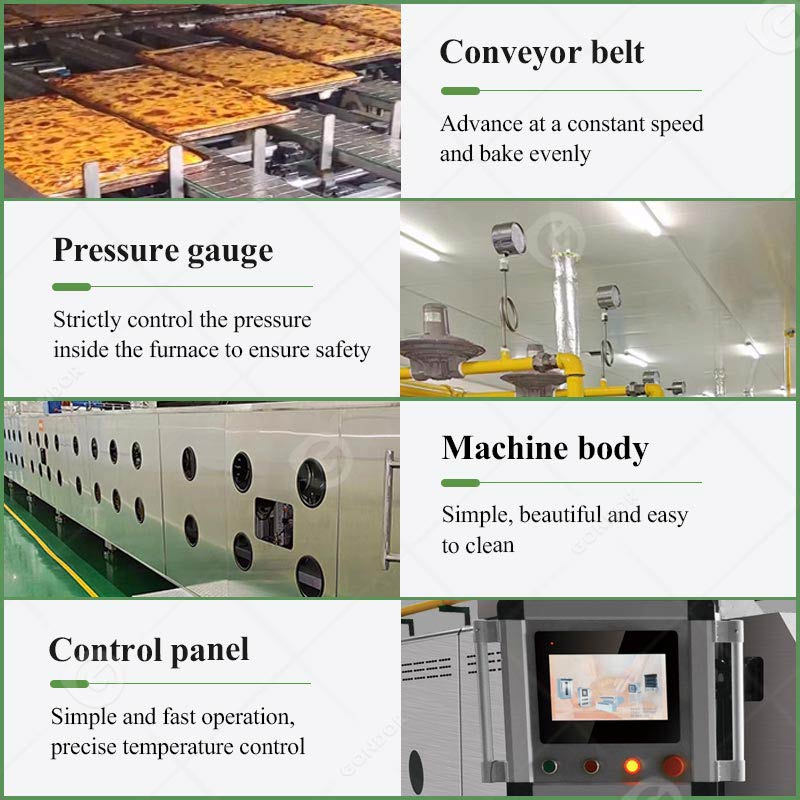

Herausragende Ausstattungsmerkmale des Gondor Tunnelofens

Der Tunnelofen integriert hohe Effizienz, Energieeinsparung und Intelligenz. Sein wissenschaftliches Design und die hochwertige Konfiguration machen die Lebensmittelverarbeitung effizienter und stabiler. Ob großtechnische Produktion oder kundenspezifische Verarbeitung spezifischer Produkte, Diese Ausrüstung kann unterschiedliche Anforderungen erfüllen und für Lebensmittelunternehmen zu einem leistungsstarken Helfer bei der Verbesserung ihrer Wettbewerbsfähigkeit werden.

Industrieller Tunnelofen: Effiziente und stabile Lösung für die Lebensmittelverarbeitung

Tunnelöfen sind mit ihrer wissenschaftlichen Feuerrohrkonfiguration zur Kernausrüstung für eine effiziente Produktion in der Lebensmittelindustrie geworden, fortschrittliche Isolationstechnologie und importierte elektrische Komponenten. Seine präzise Temperaturregelung und gleichmäßige Backfähigkeit sorgen für eine stabile Lebensmittelqualität, Das kontinuierliche Fördersystem und das energiesparende Design verbessern die Produktionseffizienz erheblich und senken die Betriebskosten. Es eignet sich für eine Vielzahl von Lebensmittelverarbeitungsszenarien, beispielsweise für Brot, Gebäck, Kuchen, Mondkuchen, usw., Unterstützung von Unternehmen bei der Erzielung von Produktionsverbesserungen. Kontaktieren Sie uns über das Anfragefeld unten oder die E-Mail oben auf der Website, um weitere Produktdetails zu erhalten und professionelle Unterstützung für Ihre Lebensmittelproduktion zu bieten!