Gondor-Flüssigkeitsfüllmaschine

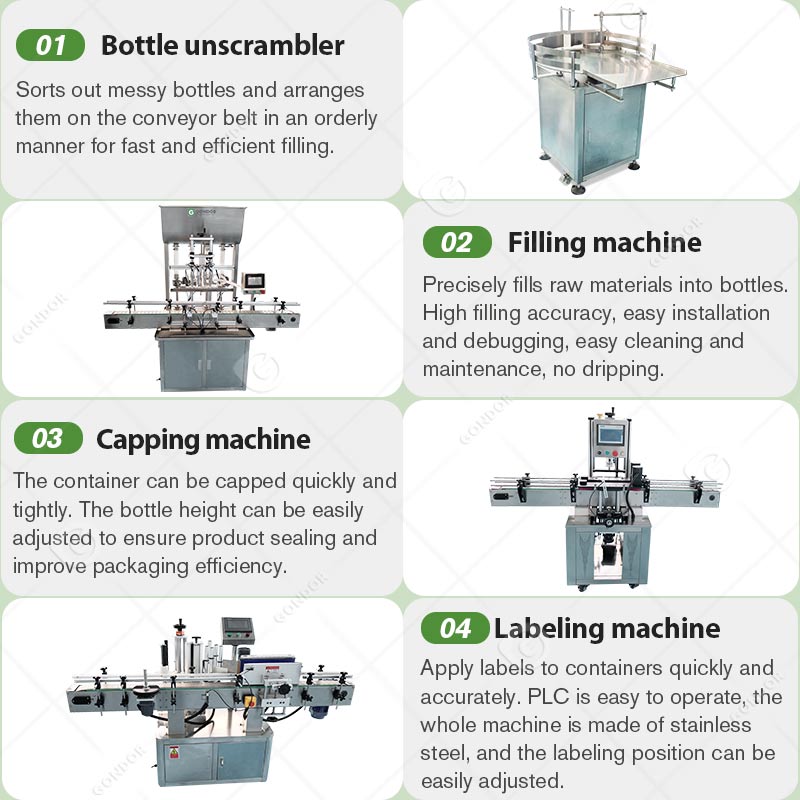

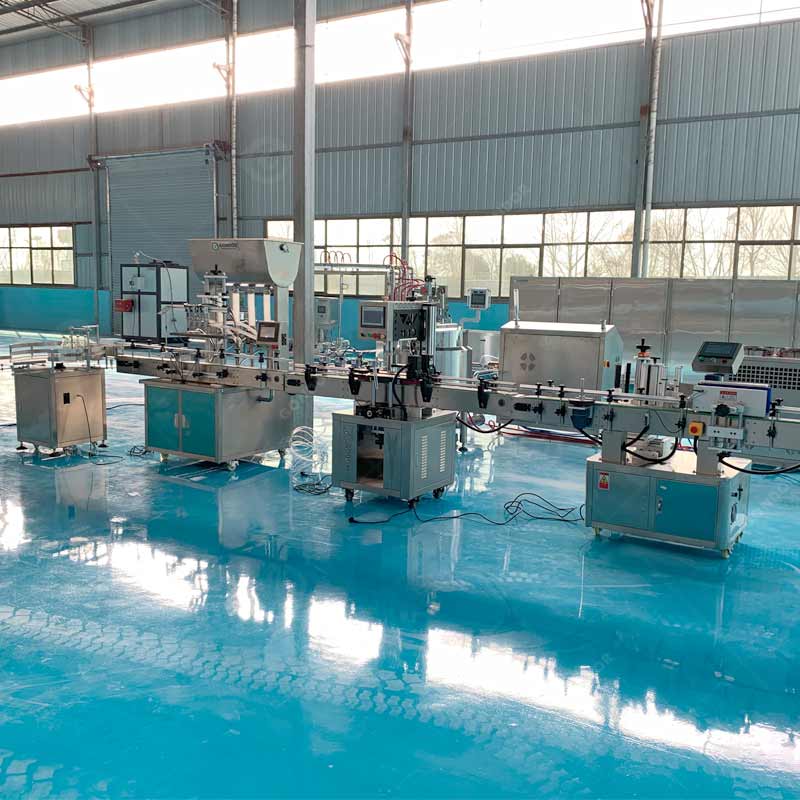

Das Flüssigkeitsabfülllinie integriert automatische Flaschensortierung, präzise Füllung, Hochgeschwindigkeitsversiegelung, und intelligente Beschriftung, Bildung eines umfassenden automatischen Verpackungssystems. Die gesamte Linie verfügt über ein intelligentes SPS-Steuerungssystem, kombiniert mit einem hochpräzisen Füllmodul, Dadurch kann der Füllfehler jeder darin enthaltenen Flüssigkeitsflasche kontrolliert werden 1%, Damit werden die Anforderungen von Hochgeschwindigkeitsgeräten erfüllt, großräumig, und Präzisionsfertigung. Gleichzeitig, Die Ausrüstung ist aus lebensmittelechtem Material gefertigt 304 Edelstahl, das den internationalen Gesundheitsstandards entspricht, und ist nicht nur stabil im Betrieb, sondern auch bequem in der Wartung, Dadurch eignet es sich sehr gut für die moderne Flüssigkeitsverpackungsindustrie.

Spezifikation der Produktionslinie für Flüssigkeitsabfüllung

| Produkte | Flaschenentschlüsseler | Füllmaschine | Verschließmaschine | Etikettiermaschine |

| Stromspannung | 220v | |||

| Leistung | 120w | 500w | 0.8kw | 1.5kw |

| Ertrag | / | 5-60 Flaschen/Min | 30-60 Stück/Min | 20-200 Stück/Min |

| Gewicht | 120kg | 800kg | 550kg | 270kg |

| Größe(mm) | 1250*1250*1350 | 2000*1250*1600 | 2000*850*1800 | 1220*1250*1470 |

| Flaschendurchmesser | / | / | ∅35-∅140mm | ∅30-∅180mm |

| Etikettenhöhe | / | / | / | 15-150mm |

| Etikettenlänge | / | / | / | 25-300mm |

| Durchmesser des Flaschenverschlusses | / | / | 20-100mm | / |

Industrieanwendungen der Produktionslinie für Flüssigkeitsabfüllung

Diese Abfüllproduktionslinie eignet sich besonders für die Verpackung verschiedener flüssiger Produkte, ein breites Branchenspektrum abdecken, einschließlich, aber nicht beschränkt auf:

Hervorragende Leistung der Flüssigkeitsproduktionslinie

Arbeitsablauf der Flüssigkeitsabfülllinie

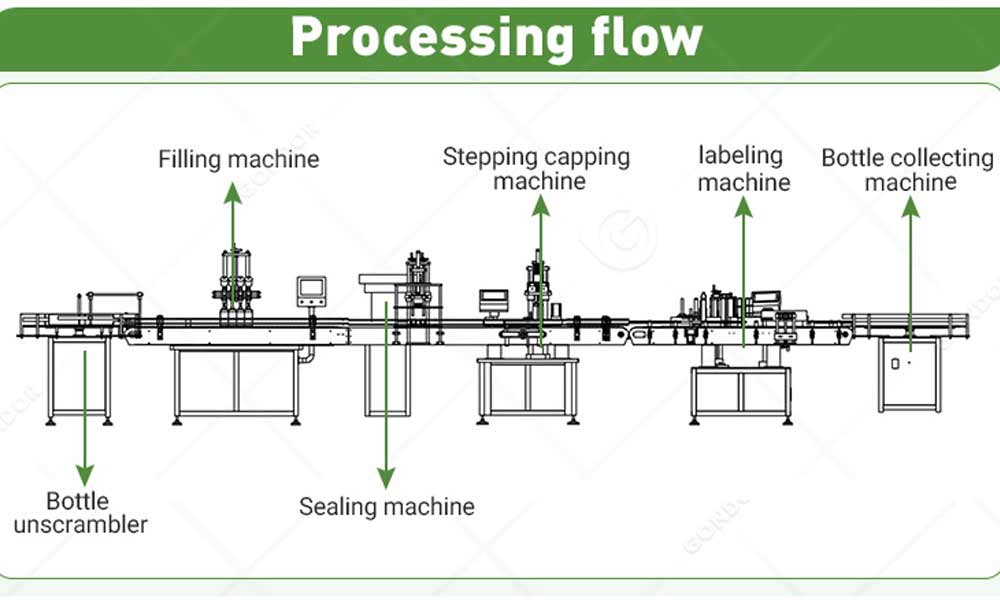

Flüssigkeitsabfüllmaschinen basieren auf Zonensteuerung und synchroner Verfolgung. Die Produktionslinie wird zentral durch eine SPS geplant. Sensoren an jeder Station (fotoelektrisch, Näherungsschalter, usw.) erfassen die Behälterposition und geben die Signale an die Steuerung zurück, welches dann die entsprechenden Mechanismen steuert (wie Füllköpfe und Verschließköpfe) präzise Aktionen im Moment der Bewegung oder Stille auszuführen.

Ein typischer Arbeitsablauf ist wie folgt (Am Beispiel von Getränkeflaschen):

Leere Flaschenversorgung: Leere Flaschen, nach der Depalettierung oder dem Austritt aus der vorgeschalteten Blasmaschine, werden in einem Stück der Produktionslinie zugeführt, gleichmäßig verteilte Säule durch ein Förderband.

Reinigung leerer Flaschen (falls erforderlich): Flaschen werden mit gereinigter Luft oder sterilem Wasser an einer umgekehrten Spülstation gespült, wobei der Flaschenhals nach unten zeigt.

Ausrichtung und Füllung: Über das Förderband werden die Flaschen zum Drehtisch oder zur Linearfüllstation der Abfüllmaschine transportiert, wobei der Flaschenhals genau unterhalb des Füllventils positioniert ist.

Sofortige Versiegelung: Gefüllte Flaschen werden sofort zur Verschließeinheit weitergeleitet, wo der Verschließkopf die Kappe ergreift und festzieht, oder eine Verschließmaschine drückt auf den Kronkorken.

Sekundärversiegelung und Etikettierung: Dabei kann es sich um eine Versiegelung mit Aluminiumfolie handeln, Schrumpffolienversiegelung, usw. Anschließend gelangt das Produkt in die Etikettiermaschine, wo das Hauptetikett präzise angebracht wird.

Online-Inspektion und -Kennzeichnung: Eine Kontrollwaage entnimmt Produkte mit zu geringem Füllvolumen; Ein optisches Inspektionssystem prüft den Flüssigkeitsstand, Versiegelung, und Etikettierqualität; Ein Tintenstrahldrucker druckt das Produktionsdatum und die Chargennummer auf die Flasche oder das Etikett.

Ausgabe des fertigen Produkts: Qualifizierte Produkte werden von einem Förderband gesammelt und von einem Sammelpacker automatisch in Kartons oder Kisten verpackt. Endlich, Sie können von einem Palettierroboter zu palettierten Stapeln gestapelt werden, warten auf die Lagerung.

Passende Ausrüstungsempfehlung

Um eine effizientere zu bauen, vollautomatische Verpackungswerkstatt, Sie können auch die Verwendung der folgenden Ausrüstung in Betracht ziehen:

- Kartonverschließer

- Tintenstrahldrucker

- Schrumpftunnelmaschine

- Fördersystem