Gondor-Dreschmaschinen für frischen Zuckermais

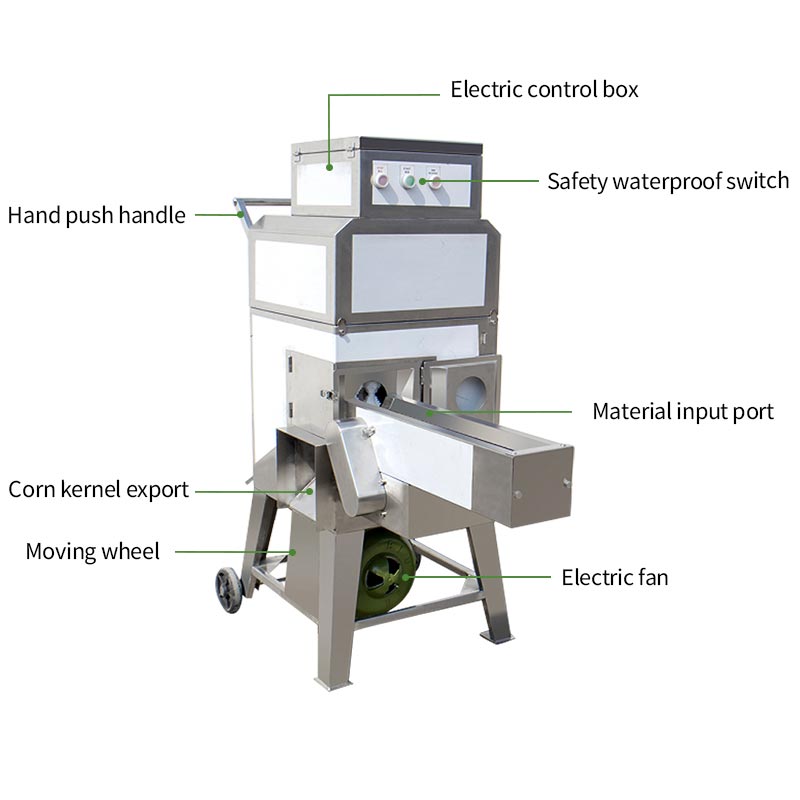

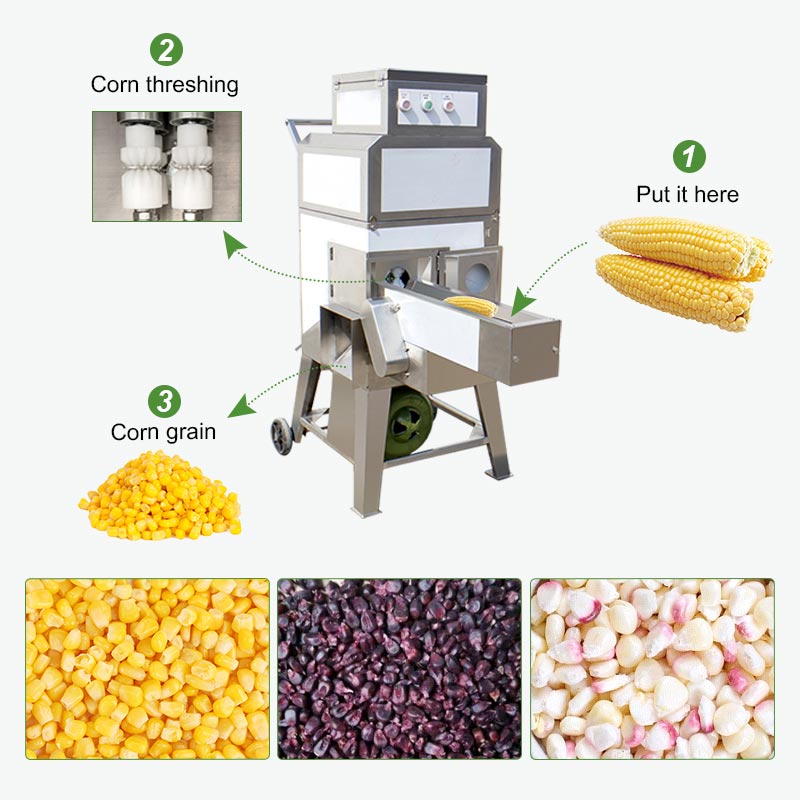

Dreschmaschine für süßen Frischmais ist ein hocheffizientes Gerät, das speziell für die Verarbeitung aller Maissorten entwickelt wurde. Darüber hinaus, Es wird häufig in Restaurants verwendet, Schulen, Kantinen, Lebensmittelverarbeitungsbetriebe, und andere orte. Zusätzlich, Es kann die Dreschtiefe entsprechend der Größe des Maiskolbens anpassen, sorgt dafür, dass die Maiskörner intakt bleiben. Das Gerät ist nicht nur einfach zu bedienen, sondern auch leistungsstabil, mit einer Dreschreinigungsrate von bis zu 99%, Dadurch wird eine saubere und hygienische Produktionsumgebung gewährleistet.

Die Frischmaisschälmaschine ist mit langlebigen Messern ausgestattet, Außerdem, es nimmt eine kleine Fläche ein, Dadurch eignet es sich für den Einsatz in einer Vielzahl von Szenarien. Außerdem, es ist leicht zu zerlegen, sicher, und zuverlässig, Dadurch wird die Effizienz des Maisdreschens erheblich verbessert, Dies macht es zur idealen Wahl für die Maisverarbeitung.

Spezifikation der Dreschmaschine für frischen Mais

| Modell | GD-168 | GD-168L |

| Kapazität | 400-500kg/h | 500-600kg/h |

| Größe | 65*60*125cm | 125*60*125cm |

| Gewicht | 90kg | 100kg |

| Stromspannung | 110v/220v/380v | 110v/220v/380v |

Hauptanwendungsgebiete der Gondor-Zuckermais-Dreschmaschine

Wie zum Beispiel Restaurants, Hotels, usw., Wird zur Verarbeitung von frischem Mais verwendet.

Bieten Sie effiziente Lösungen für die Maisverarbeitung im großen Maßstab.

Verbessern Sie die Effizienz der Maisverarbeitung in Kantinen.

Wird zum Dreschen von Mais in großem Maßstab verwendet, um den Produktionsbedarf zu decken.

Wird zum Dreschen von Mais in großen Mengen während der Erntesaison verwendet.

Helfen Sie mit, neue Maisprodukte oder Verarbeitungstechnologien zu entwickeln.

Bieten Sie Verkäufern oder Kunden das Dreschen von Mais vor Ort an.

Häufige Verwendungszwecke der Zuckermais-Dreschmaschine

Die Frischmais-Dreschmaschine verwendet eine Kombination aus rotierenden Messerwalzen aus Edelstahl, elastische Begrenzer, und gerichtete Zuführung zu “schneiden” statt “Träne” frische Ähren mit einem Feuchtigkeitsgehalt von über 60%, sorgt für einen sauberen Schnitt, keine kaputten Kerne, und kein Saftverlust. daher, es hat viele Anwendungen.

- Gefrorene Maiskörner: Nach dem Dreschen sofort blanchiert und IQF schnell eingefroren, Ganzjährige Belieferung von Restaurants und Supermärkten.

- Maiskonserven/Verzehrfertige Becher: Verbunden mit der Befüllung, Versiegelung, und Sterilisationslinien zur Herstellung ganzer Kerne, Paste, oder Rahmmais.

- Maissaft und Getränke: Ganze Kerne ohne Bruch erleichtern das spätere Entsaften, enzymatische Hydrolyse, und Gärung.

- Unternehmen für die Zubereitung von Mahlzeiten: Wird in Salaten verwendet, Pizzabelag, und Babynahrungszutaten.

- Samenvermehrung: Minimale Schäden beim Kernschneiden gewährleisten die Lebensfähigkeit der Keime, erleichtert das anschließende Trocknen und Beschichten.

Wesentliche Arbeitsvorteile der Zuckermais-Dreschmaschine von Gondor

Gondor-Zuckermais-Dreschmaschine – Hilft bei der effizienten Maisverarbeitung

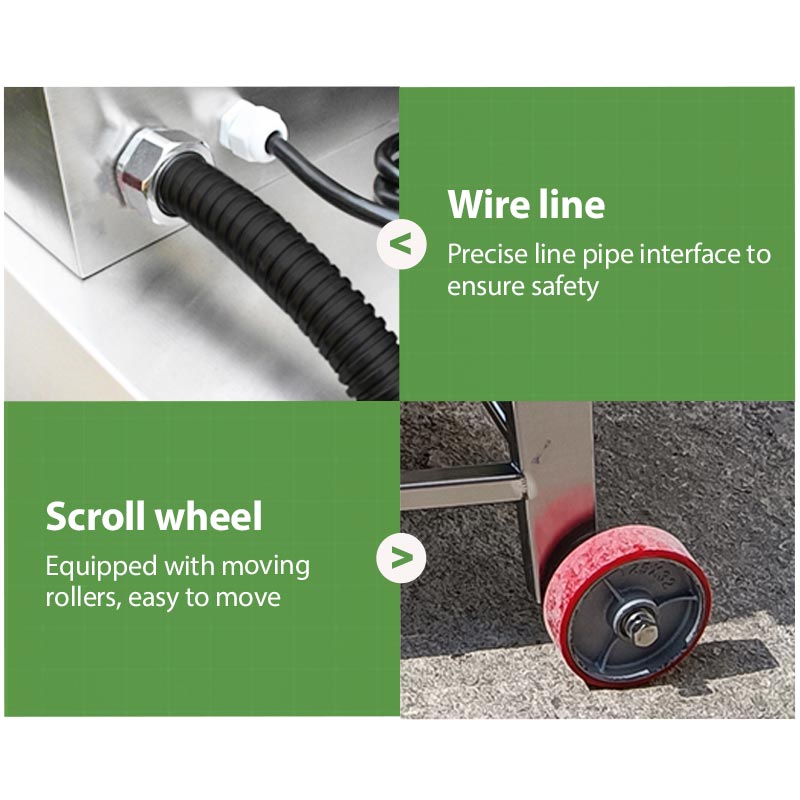

Die Gondor-Dreschmaschine für süßen Frischmais ist eine effiziente Maschine, dauerhaft, und flexible Maisverarbeitungsgeräte, die speziell für die verschiedenen Anforderungen beim Dreschen von Mais entwickelt wurden. Es werden Edelstahlschneider verwendet, die nicht nur eine extrem hohe Verschleißfestigkeit, sondern auch eine hervorragende Anpassungsfähigkeit aufweisen, Dadurch sind sie für den Einsatz in feuchten Umgebungen geeignet. Darüber hinaus, Sein innovatives Design der Auslassöffnung verbessert die Dreschgeschwindigkeit und -leistung erheblich, Damit eignet es sich ideal für groß angelegte Verarbeitungsszenarien. Zusätzlich, Es ist mit mobilen Rollen für eine bequeme und flexible Bewegung ausgestattet, und sorgt so für Komfort, sicher, und zuverlässigen Betrieb. Außerdem, Die Bruchrate des Maiskörners ist gering, Aufrechterhaltung der Produktintegrität. daher, Senden Sie jetzt eine Anfrage, um weitere Produktdetails zu erfahren, Bestellen Sie dieses ideale Maisverarbeitungsgerät, und letztendlich die Produktionseffizienz verbessern!