Hersteller von Wurst-Vakuumfüllern

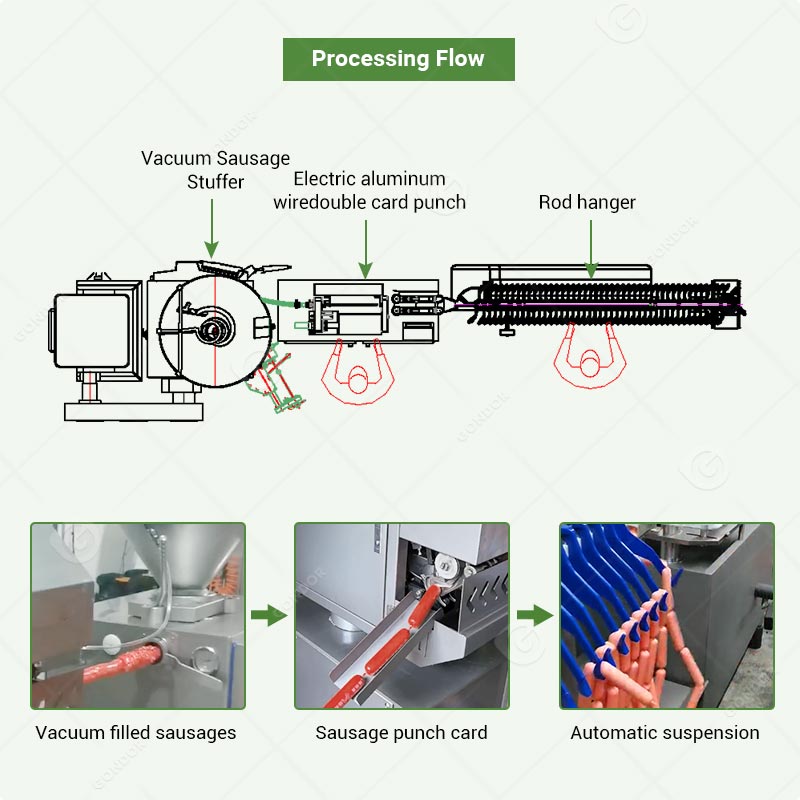

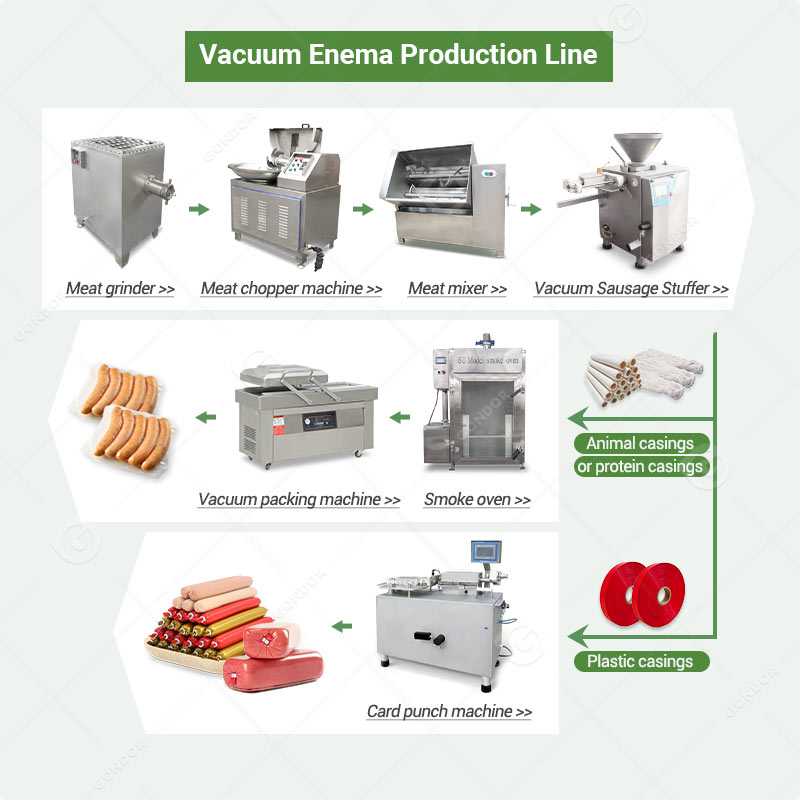

Gondor stellt einen Profi zur Verfügung Vakuum-Wurstfüller, welches sich ideal für die Wurstherstellung eignet, Schinken, Mittagsfleisch, und andere Fleischprodukte. Zur Kernausstattung gehört eine Vakuumwurstfüllmaschine, eine elektrische Doppelkartenstanzmaschine aus Aluminiumdraht, und eine Stangenaufhängemaschine, Gewährleistung eines effizienten und präzisen Produktionsprozesses. Die Vakuumfüllmaschine unterstützt Natur- und Proteindärme, Bietet genaue Quantifizierung und automatisches Verdrehen.

Zusätzlich, Für eine vollautomatische Produktion kann es mit der Doppelkartenmaschine gekoppelt werden. Darüber hinaus, Die Lochkartenmaschine liefert eine hohe Präzision, Korrosionsbeständigkeit, und stabile Leistung, während die Stangenaufhängemaschine die Bedienung durch automatisches Aufhängen der Würste vereinfacht, die Effizienz deutlich steigern. Ob für Kleinserien oder Großserienfertigung, Mit dieser Produktionslinie können Sie vielfältige Anforderungen erfüllen und gleichzeitig Zeit und Kosten sparen.

Spezifikation der Vakuum-Wurstfüllmaschine

|

Name |

Leistung(kW) | Stromspannung(v) | Gewicht(kg) | Größe(mm) | Kapazität(kg/h) |

| Vakuum-Wurstfüller | 6 | 380,50HZ | 560 | 1100*1100*1850 |

220 |

|

Elektrischer Doppelkartenstanzer aus Aluminiumdraht |

2.3 | 220V,50HZ | 380 | 760*800*1450 | 60-80Zeiten/Minute |

| Stangenaufhänger | / | 380,50HZ | 160 | 2600*450*1300 |

1200Zeiten/Minute |

Anwendbare Branchen des Gondor-Vakuumwurstfüllers

Der Vakuum-Wurstfüller wird aufgrund seiner hohen Effizienz häufig in der fleischverarbeitenden Industrie eingesetzt, Präzision und Vielseitigkeit, insbesondere in Betrieben mit hohen Anforderungen an Abfüllqualität und Produktionseffizienz. Es kann nicht nur den Bedarf der traditionellen Fleischproduktion decken, eignet sich aber auch für den vielfältigen Einsatz neuer Proteinprodukte und die Spezialdarmverarbeitung, und ist eine ideale Wahl im Bereich der Lebensmittelverarbeitung. Im Folgenden sind die wichtigsten anwendbaren Branchen aufgeführt:

Bemerkenswerte Funktionsmerkmale der Vakuumfüllwurstmaschine

Die Vakuumfüllwurstmaschine integriert hohe Effizienz, Präzision und Intelligenz, und ist eine unverzichtbare Produktionsausrüstung für moderne Fleischverarbeitungsbetriebe. Sein Design berücksichtigt die unterschiedlichen Bedürfnisse der Anwender und eignet sich für die Herstellung verschiedener Arten von Hüllen und Fleischprodukten. Im Folgenden sind die bemerkenswerten Funktionsmerkmale des Geräts aufgeführt:

Funktionsprinzipien der Wurst-Vakuumfüller-Hersteller

Online-Drahtbindung: Synchronisiert mit dem Kartenlesersignal, Aluminiumdraht wird sofort nach dem Verdrehen festgebunden, um ein Lösen zu verhindern, unbemannten Betrieb zu erreichen.

Vakuum-Wurstfüller – Ideal zur Verbesserung von Effizienz und Qualität

Der Vakuum-Wurstfüller ist eine effiziente Lösung für die moderne Fleischwarenverarbeitung. Es integriert eine quantitative Vakuumbefüllung, automatisches Verdrehen, Präzise Taktung und automatische Hängestangenfunktionen. Es eignet sich zur Herstellung von Wurstwaren, Schinken, Mittagsfleisch und andere Produkte. Mit Kompatibilität mit einer Vielzahl von Gehäusen, Hochgeschwindigkeitsautomatisierung und hervorragende Leistung, Diese Produktionslinie hilft Unternehmen, die Produktionseffizienz deutlich zu verbessern, Arbeitskosten senken, und sorgen für Produktkonsistenz und hohe Qualität. Ob Kleinserienfertigung oder Großserienfertigung, Unsere Ausrüstung kann die Anforderungen problemlos erfüllen.

Bestellen Sie Gondor Anlagen zur Wurstherstellung Jetzt, Oder füllen Sie das unten stehende Anfragefeld aus, um weitere Einzelheiten zu erfahren und professionelle Unterstützung zu erhalten!