Máquina de dulces con rodillos por lotes Gondor

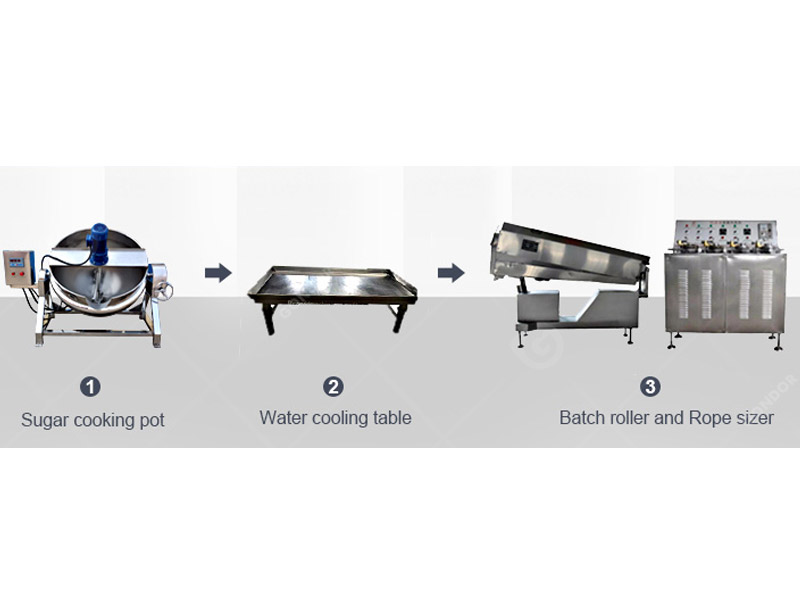

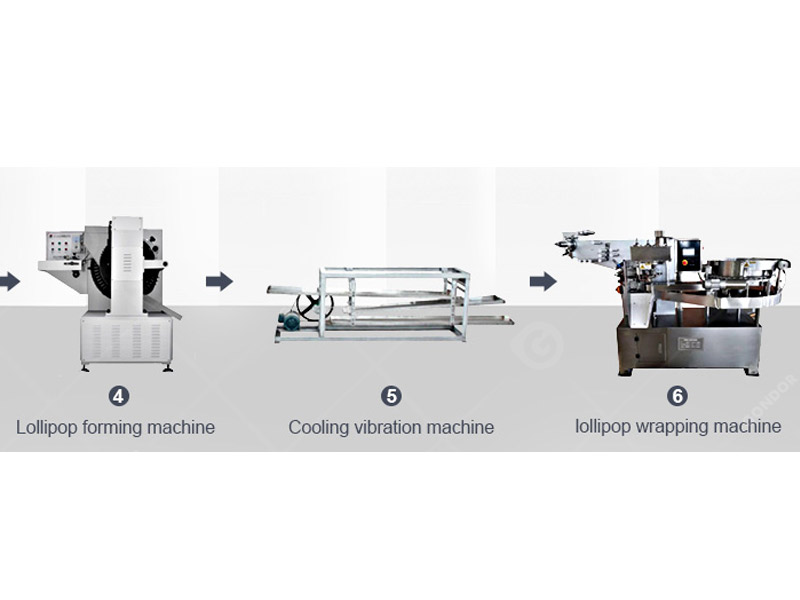

El batch roller candy machine está diseñado específicamente para la producción de tiras de caramelo. Hecho de acero inoxidable espesado, es seguro y duradero, ofreciendo bajo nivel de ruido y alta eficiencia, which significantly reduces labor intensity. para operar, simplemente coloque la masa de azúcar a la temperatura adecuada en el lecho de rodillos con aislamiento térmico. Luego, el equipo ajusta el espaciado y la velocidad de los rodillos de tira., permitir que la masa de azúcar se introduzca suavemente en una columna de azúcar cónica y posteriormente se estire en tiras finas para moldear. Además, es compatible con varias máquinas de moldeo. Con fácil operación, funciones versátiles, y apoyo al trabajo continuo, Esta máquina mejora enormemente la eficiencia de producción.. En general, Este equipo es un asistente eficiente en la producción de tiras de caramelo., ayudando a las empresas a optimizar sus procesos.

|

Nombre

|

Fuerza(kilovatios)

|

Peso(kilos)

|

Dimensiones externas(milímetros)

|

Capacidad

|

|

El rodillo por lotes

|

4.75

|

450

|

2100*600*1150

|

150-300 piezas/min

|

|

El medidor de cuerda

|

3.3

|

430

|

1400*800*1300

|

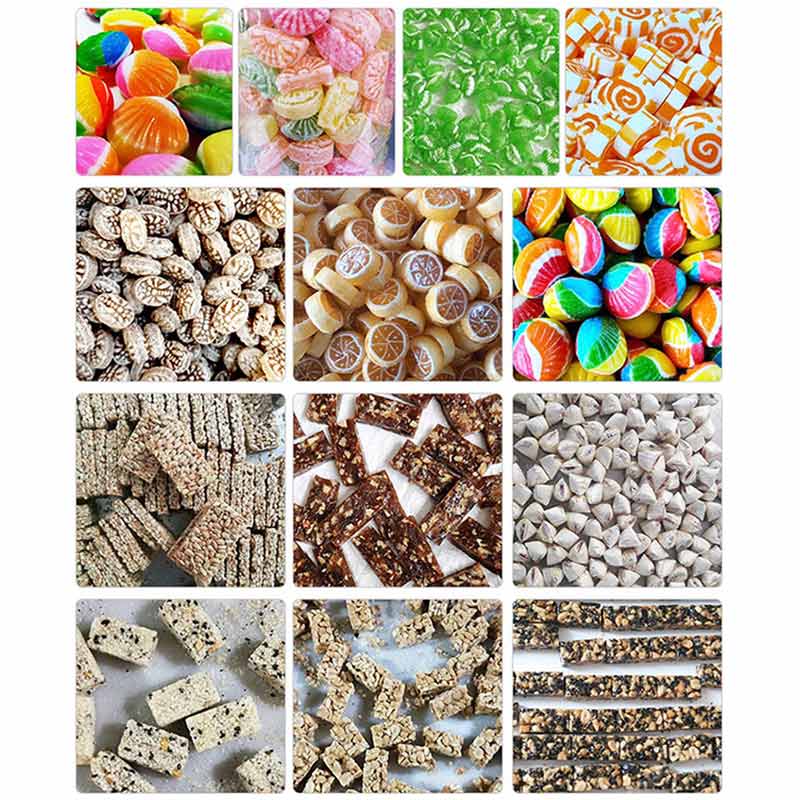

Áreas de demanda de caramelos rodillos por lotes Gondor

Este eficiente rodillo por lotes se usa ampliamente en múltiples campos para satisfacer diferentes necesidades de producción debido a su fácil operación., Gran aplicabilidad y adaptabilidad a una variedad de máquinas de moldeo.. Las siguientes son las principales áreas de demanda de este equipo.:

Excelentes ventajas de rendimiento de la máquina de rodillos por lotes Gondor

El rodillo por lotes Gondor se usa ampliamente en el campo de la producción de dulces con sus ventajas de alta eficiencia., durabilidad, fácil operación y multifunción, Ayudar a las empresas a mejorar significativamente la eficiencia de la producción y la consistencia de la calidad del producto.. Es adecuado para una variedad de equipos de moldeo y admite operación continua., lo que lo convierte en una opción ideal para que las empresas de producción de dulces optimicen el flujo del proceso., Reducir costos y mejorar la competitividad en el mercado..

Máquina de dulces con rodillos por lotes Gondor – La mejor opción para una producción eficiente

If you are looking for professional equipment to improve the production efficiency of candy, Gondor batch roller candy machine is your ideal production partner. The equipment is made of food-grade thickened stainless steel, y el funcionamiento es sencillo e intuitivo. The extension and shaping of candy bars can be easily completed by accurately adjusting the distance and speed of rollers, and it can be smoothly docked with various molding machines, flexibly adapting to the production requirements of different scales and processes.

If you want to build a complete candy production line, you can use this equipment with the hervidor de vapor con chaqueta to realize the seamless connection from syrup boiling to candy bar forming. También se puede conectar con un máquina formadora de piruletas to efficiently produce lollipop products with the same shape. Choosing the Gondor rolling and drawing machine is not only to introduce a device, but also to create a stable, flexible and efficient candy production process. Contact us now to get customized solutions and exclusive quotations!