A secador por pulverización centrífugo Es un eficiente equipo de secado especialmente diseñado para transformar rápidamente líquidos., emulsión, o materiales en suspensión en polvo o productos granulares. El equipo atomiza el líquido de alimentación en finas gotas a través de un atomizador centrífugo giratorio de alta velocidad y luego entra en contacto total con el gas de secado a alta temperatura para realizar la evaporación instantánea del agua y completar el rápido proceso de secado.. El polvo terminado tiene buena fluidez y tamaño de partícula uniforme., que es una solución de secado ideal para alimentos, industria química, medicina y otras industrias.

| Modelo | GD-5 | GD-25 | GD-50 | GD-100 | GD-150 | GD-200-2000 |

| Temperatura de entrada'C | 140-350 controlado automáticamente | |||||

| Temperatura de salida'C | ~80-90 | |||||

| máx.. capacidad de evaporación de agua kg/h | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| Modo de transmisión de boquilla de pulverización centrífuga | Transmisión de aire comprimido | Transmisión mecánica | ||||

| Velocidad de rotación(rpm) | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| Diámetro del disco de pulverización(milímetros) | 50 | 100 | 120 | 140 | 150 | 180-340 |

| Suministro de calor | Electricidad | Electricidad

+vapor |

Electricidad+vapor,

fueloil y gas |

Resuelto por los propios usuarios. | ||

| Potencia máxima de calefacción eléctrica (kilovatios) | 9 | 36 | 63 | 81 | 99 | / |

| Dimensiones generales(metro) | 1.8×0.93 x2.2 | 3×2.7×4.26 | 3.7×3.2×5.1 | 4.6×4.2×6 | 5.5×4.5×7 | Depende de las condiciones concretas. |

| % de recolección de polvo seco | ≥95 | |||||

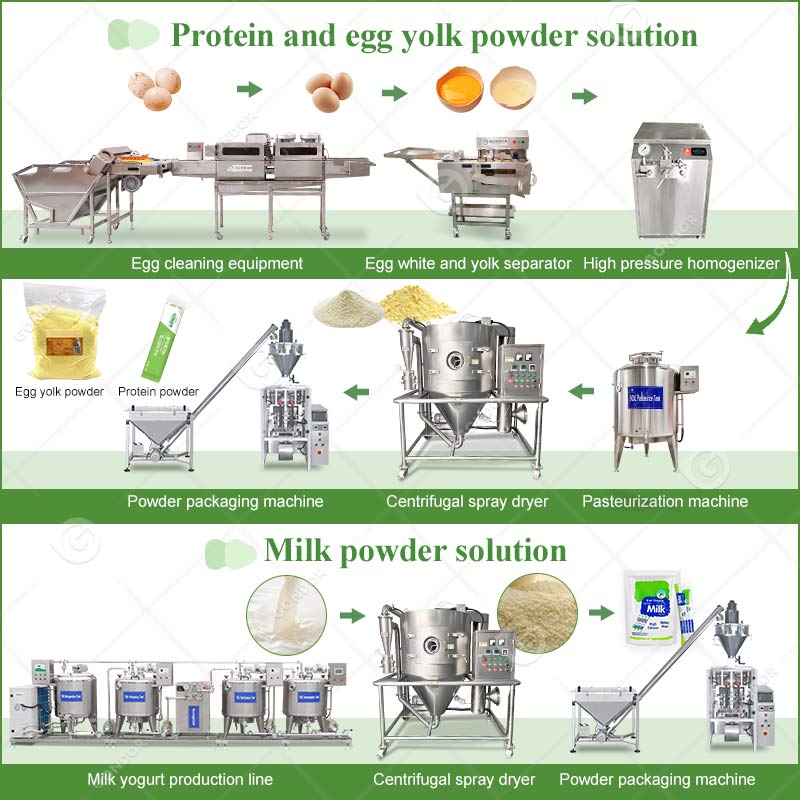

El mercado de uso de la máquina secadora por pulverización

Este equipo es ampliamente utilizado en las siguientes industrias:

Características clave & Ventajas del secador por pulverización

Herramienta de secado recomendada

El secador por pulverización centrífugo, con sus principales ventajas de alta eficiencia, precisión, y protección del medio ambiente, se está convirtiendo en el equipo clave de las soluciones globales de secado de polvo. No importa las fábricas de alimentos, empresas farmacéuticas, o líneas de producción química, pueden beneficiarse de ello y realizar el salto perfecto de “líquido a polvo”. Si está interesado en otros equipos relacionados, tal como un liofilizador al vacío o un pequeña máquina liofilizadora, Continúe navegando por nuestra página de productos o comuníquese con el equipo de ventas profesional para obtener más ayuda..