Gondor Chocolate Conching Machine Introduction

Our advanced máquina de conchado de chocolate is a specialized solution engineered for the meticulous demands of modern chocolate production. Equipped with a state-of-the-art servo-controlled grinding system and an intuitive touchscreen interface, this chocolate conche machine allows for precision particle size reduction down to ≤20µm . With adjustable refining cycles ranging from 7 a 9 horas, the equipment features a temperature-regulated chamber and optimized blade geometry to ensure a perfectly smooth and uniform texture.

Gondor Chocolate Conching Machine Models

Available in various specifications from 12L to 1000L, this series offers the flexibility to support everything from laboratory R&D to large-scale industrial production. Utilizing an optimized steel ball grinding system, each model consistently achieves a professional fineness of 18-25 microns within a high-efficiency processing timeframe.

| Modelo | GD-CBMM12 | GD-CBMM50 | GD-CBMM500 | GD-CBMM1000 |

| Voltaje | 2201P | 3803P | ||

| Capacidad | 12l | 50l | 500l | 1000l |

| Fuerza | 750w | 3kilovatios | 30kilovatios | |

| Tiempo de molienda | 3-4h | 5-6h | 6-7h | |

| Weight of Grinding Ball | 20kilos | 160kilos | 1125kilogramos-1500kg | 2250kilogramos-3000kg |

| Output Fineness | 22-25 micrón | 18-25 micrón | ||

| Diameter of Steel Ball | 10milímetros | |||

| Tamaño de embalaje | 70*76*74centímetro | 100*65*185centímetro | 125*155*165centímetro | 250*160*265centímetro |

| Peso del embalaje | 90kilos | 400kilos | 1850kilos | 2550kilos |

Gondor Chocolate Conching Machine Application & Materias primas

Transforms high-content cocoa liquor and butter into premium dark chocolate with a silky texture and intense aroma through 7-9 hours of refining.

Blends milk powder and sweeteners with cocoa butter to eliminate grittiness and achieve a velvety mouthfeel with rich, creamy notes.

Supports precision processing of different bean origins, utilizing temperature control to release the unique aromatic profiles of single-origin cocoa.

Regulates the mixture of vegetable fats and additives to ensure perfect fluidity and a glossy finish for various confectionery glazing tasks.

Grinds hazelnuts or almonds to sub-20 micron fineness to create ultra-smooth, particle-free pastes for high-end dessert and pastry centers.

Adapts perfectly to alternative sweeteners and plant-based ingredients to deliver superior quality for sugar-free and vegan chocolate products.

Gondor Chocolate Conching Machine Target Markets & Aplicaciones

Utilize high-capacity models to achieve mass production while ensuring consistent quality across every batch of chocolate mass.

Produce essential ingredients for filled candies and coated snacks to enhance the sensory characteristics of the final products.

Manufacture high-standard cocoa butter, revestimientos, and nut pastes to supply premium base ingredients for the baking market.

Empower makers to develop artistic chocolates with unique textures and flavors through precise control of grinding parameters.

Meet the demand for fresh chocolate decorations and fillings in high-end catering to elevate the overall quality of desserts.

Provide accurate experimental data to support new formula R&D, ingredient testing, and technical process optimization.

Target the health-conscious market by efficiently producing differentiated products like sugar-free, vegano, or functional chocolates.

Chocolate Conching Machine Operation Process

Gondor Chocolate Conching Machine Details

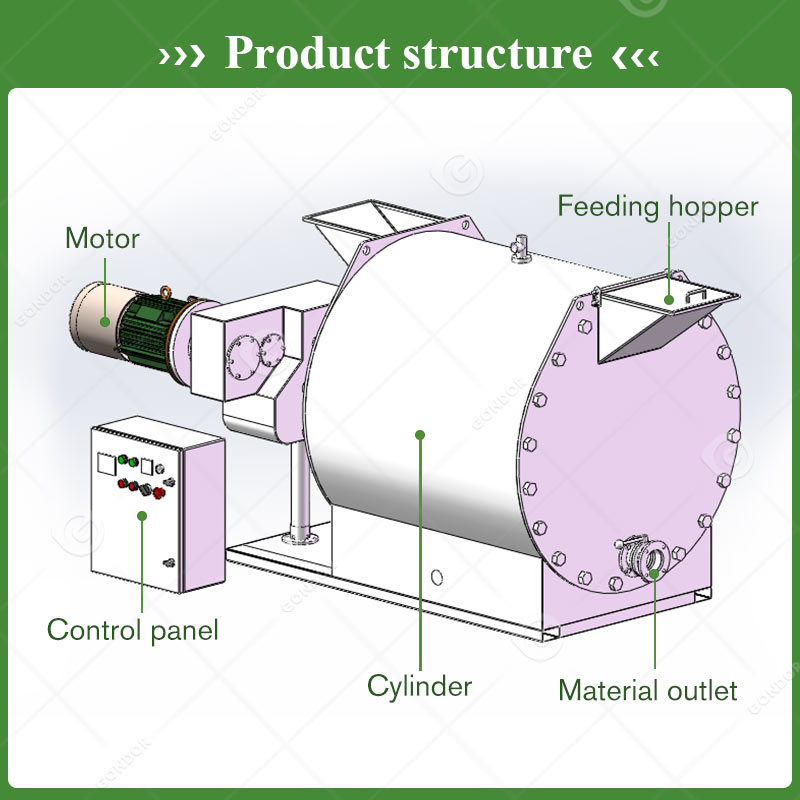

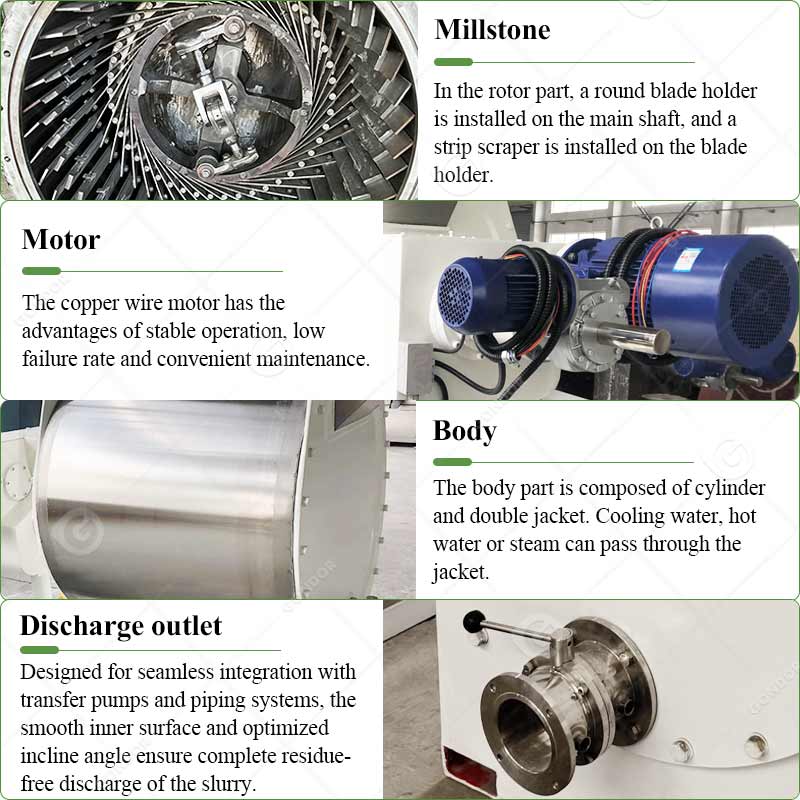

- Grinding System (Rotor Assembly): The main shaft features a circular blade holder equipped with precision scrapers to ensure continuous and uniform material processing.

- High-Performance Motor: The premium copper-wire motor delivers stable operation and low failure rates while ensuring easy maintenance and long-term reliability.

- Chamber Assembly: The body part is composed of cylinder and double jacket. Cooling water, hot water or steam can pass through the jacket.

- Optimized Discharge Outlet: Engineered for seamless connection to pumps and pipes, the polished interior and calculated tilt facilitate a complete, residue-free flow of chocolate mass.

Gondor Chocolate Conching Machine Features

- Control inteligente: Touchscreen HMI and PLC systems enable precise regulation of temperature and processing time.

- Dual-Function Blades: Innovative grinding blades achieve highly efficient refining and conching in a single process.

- Precision Consistency: Automatic viscosity monitoring ensures every batch reaches a uniform fineness of 20 micrones.

- Eficiencia Energética: Advanced motors reduce power consumption by 15% compared to conventional grinding models.

- Quality Optimization: Integrated dehydration and deodorization functions effectively enhance the final chocolate flavor profile.

- Superior Fineness: High-performance grinding system consistently delivers an ultra-smooth and delicate mouthfeel.

- Diseño fácil de usar: The transparent operation interface allows for effortless adjustment and real-time process observation.

- Versatile Processing: Engineered for wide applications ranging from pure cocoa liquor to various specialty nut pastes.