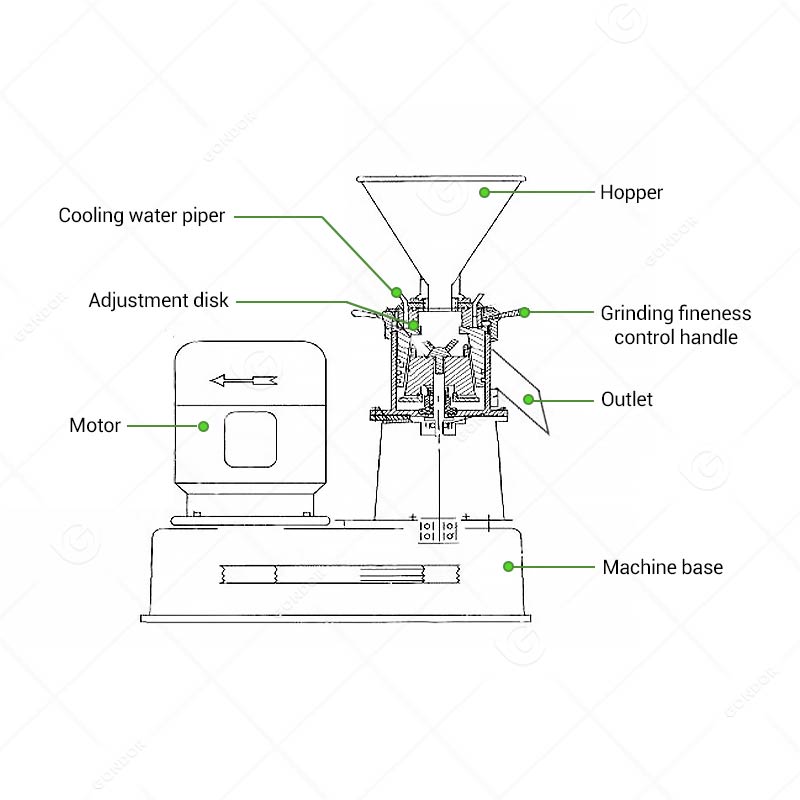

Gondor Commercial Peanut Butter Colloid Mill Introduction

El commercial peanut butter colloid mill is an efficient wet grinding and emulsifying solution designed for industrial peanut butter making. This colloid mill for nut butter machine integrates ultra-fine grinding, homogeneizar, and mixing to produce smooth, uniform peanut butter with stable texture and consistent quality.

Gondor Peanut Butter Making Colloid Mill Machine Models

Below are the model parameters of our commercial peanut butter making machines. If you would like to know more details or customize the product, por favor contáctenos. We will offer you free consultation and detailed quotations.

| Modelo | Voltaje | Tamaño(milímetros) | Peso | Capacidad |

| GD-70 | 3kilovatios(Monofásico, 220v) | 650x320x650 | 70kilos | 60-80kg/hora |

| GD-80 | 5.5kilovatios(Three-phase, 380v) | 800x350x800 | 170kilos | 100-150kg/hora |

| GD-130 | 11kilovatios(Three-phase, 380v) | 1000x350x1000 | 270kilos | 200-300kg/hora |

| GD-180 | 30kilovatios(Three-phase, 380v) | 1200x450x1200 | 470kilos | 500-800kg/hora |

| GD-200 | 37kilovatios(Three-phase, 380v) | 1250x500X1200 | 500kilos | 800-1000kg/hora |

Applications of Commercial Peanut Butter Colloid Mill

Miseria, manteca de cacahuete, leche de maní, semillas de sésamo, tahini, maíz, soja, soy sauce, pastas de nueces, dairy-based semi-liquid products.

Pasta dentífrica, detergents, champús, shoe polish, and other paste or emulsion-type products.

Paints, pigmentos, tintes, revestimientos, lubricants, and similar viscous or emulsified materials.

Materials requiring ultra-fine wet grinding and homogenization in plastic, textile, papel, and biochemical industries.

Should I Choose a Square Outlet or a Circulating Pipe Outlet?

The choice depends on the material viscosity and processing requirements. The square outlet is suitable for medium- and high-viscosity materials that do not require reflux or secondary grinding, como mantequilla de maní, chili sauce, and sesame paste, allowing direct discharge. The circulating pipe outlet is designed for low-viscosity materials that require reflux or further grinding, such as fruit juice and soy milk, to achieve finer and more uniform results.

Peanut butter with a grainy texture or insufficient smoothness is usually caused by the following factors:

Insufficient Raw Material Pre-treatment

Inadequate roasting, incomplete skin removal, or oversized peanut particles can negatively affect the grinding process and leave a gritty texture in the final product.

Mismatched Grinding Parameters

Improper settings such as rotor speed, grinding gap, or feeding rate may result in insufficient shear force, preventing the peanuts from being finely ground.

Insufficient Grinding or Lack of Circulation Grinding

For peanut butter that requires higher fineness, a single pass may not be enough. Circulation or reflux grinding is often necessary to further improve smoothness and uniformity.

Variations in Oil Content or Formulation

Different peanut varieties, oil content levels, and formulation ratios can influence grinding performance and require parameter adjustments.

You can significantly enhance the smoothness and consistency of peanut butter by improving raw material preparation, optimizing machine settings, and applying circulation grinding when needed.

Features of Gondor Commercial Peanut Butter Colloid Mill

- Conveniente & Operación eficiente: Compact structure enables quick start-up and smooth processing.

- Fácil de operar: Simple operation design reduces training time and labor requirements.

- Wide Application Range: Suitable for various paste, semi-liquid, and emulsified materials.

- Construcción de acero inoxidable de calidad alimentaria.: Higiénico, resistente a la corrosión, and compliant with food processing standards.

- Alta eficiencia de producción: Continuous working capability ensures stable output and consistent quality.

See the Peanut Butter Colloid Mill in Action

To help you better understand the working performance and grinding results, we have prepared a real production demonstration of the peanut butter colloid mill. From raw peanut feeding to ultra-fine grinding and smooth butter discharge, you can clearly observe the machine’s stable operation, procesamiento eficiente, and consistent output quality. See how easily it transforms peanuts into rich, creamy peanut butter.

Equipo de soporte recomendado

To build an efficient línea de producción de mantequilla de maní, the peanut butter colloid mill can be combined with the following supporting equipment to form a complete processing solution:

- Peanut Sheller

- Peanut Roasting Machine

- Peanut Skin Remover

- Máquina de llenado