Máquina para fabricar azúcar cristalina Gondor

En la industria mundial de procesamiento de alimentos, Azúcar cristal de alta pureza., cristal regular, y la alta transparencia es siempre representativa de los productos de azúcar de alta gama.. Nuestro maquina para hacer azucar de roca Utiliza tecnología de cristalización avanzada y un sistema de control automático preciso., permitiendo la producción estable de azúcar de roca monocristalino y policristalino para cumplir con diversos requisitos de mercado y aplicaciones..

Ya sea un caramelo de alta gama que persigue una apariencia exquisita., o una bebida o producto farmacéutico que prioriza el sabor y la pureza, este equipo puede proporcionarle una solución perfecta.

Máquina para fabricar azúcar Crystal Rock

| Modelo | Fuerza | Velocidad de centrifugación | Dimensiones exteriores | Peso |

| Máquina de azúcar de roca monocristalina | 0.75kilovatios | 800- 1000rpm | 2300*1500*1600milímetros | 1200kilos |

| Máquina de semillas de cristal | 1.1kilovatios | / | 1200*600*1350milímetros | 180kilos |

| Azucarero helado grande | 15.75kilovatios | / | ø1200X1500mm | 220kilos |

| Balde de cristalización policristalina | / | / | 400*400*1500milímetros | / |

Rango de mercado de aplicaciones de la máquina para fabricar azúcar de roca

La línea de producción de azúcar cristal se utiliza ampliamente en muchas industrias.:

Usado para té, bebidas saludables, agua azucarada tradicional china, etc..

La fabricación de dulces de alta gama como las golosinas., galletas, y chocolate.

Gránulos de fórmula de medicina tradicional china, jarabe medicinal, y otros alimentos saludables.

Para satisfacer las necesidades de lotes pequeños y productos de azúcar de alto valor agregado..

Fuertes ventajas de uso de la línea de producción de azúcar cristal

Descripción general del principio del proceso

El almíbar se calienta a una temperatura específica. (como 120 ℃) en un ambiente de vacío para formar una solución sobresaturada. Después de agregar cristales semilla, la temperatura se baja lentamente en un tanque de cristalización, y las moléculas de azúcar se agregan gradualmente para formar un solo cristal regular.

El almíbar se vierte en un barril de acero inoxidable o en una caja de control de temperatura., y el azúcar se cristaliza naturalmente mediante enfriamiento natural y agitación moderada., formando un gran azúcar de roca compuesto de múltiples cristales pequeños. El proceso se acerca más a la forma tradicional..

Usos principales de una máquina para fabricar azúcar de roca:

Capaz de producir a gran escala varios productos de azúcar de roca., incluido:

- Azúcar de roca monocristalino (azúcar de semilla de roca)

- Azúcar de roca policristalino (azúcar de roca vieja, azúcar de roca cruda, azúcar de roca amarilla)

- Azúcares de roca funcionales (como jugo de pera y azúcar de roca, azúcar de roca de crisantemo, y otros productos aromatizados).

Cree una solución completa para la producción de azúcar

Además de la máquina para fabricar azúcar de roca., También le proporcionamos una serie de equipos estrechamente relacionados con el procesamiento del azúcar para ayudarle a construir una línea de producción de todo el proceso, desde el procesamiento de la materia prima hasta el envasado del producto terminado..

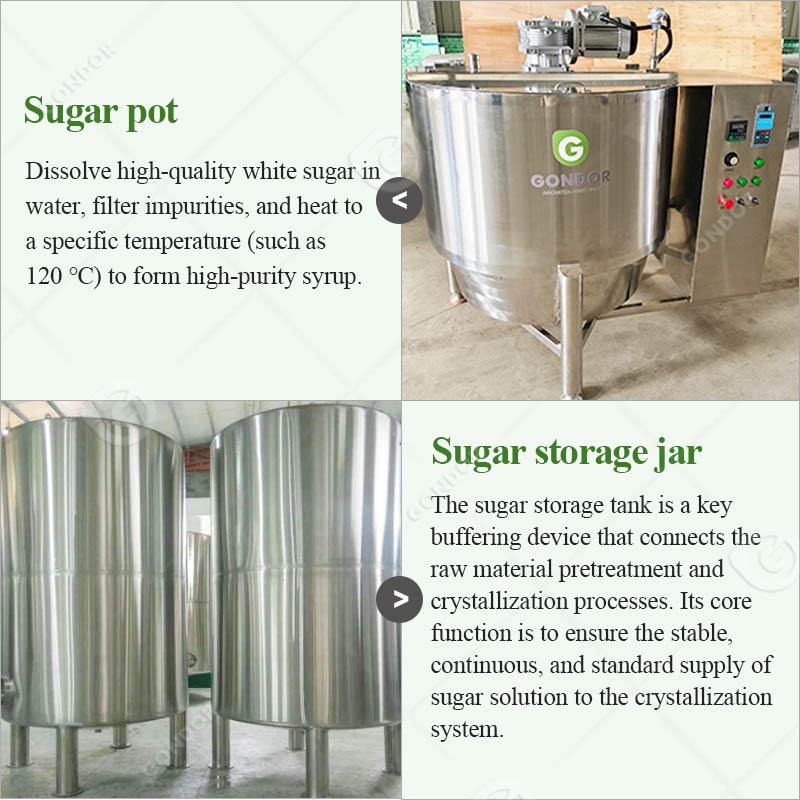

- Sistema de fusión de azúcar: Disuelva el azúcar blanco de alta calidad de manera eficiente para garantizar que la solución de azúcar sea pura y libre de impurezas..

- Unidad de evaporación al vacío: Jarabe concentrado a baja temperatura, manteniendo el sabor y el color.

- Automático Máquina de embalaje: Embolsado de especificaciones múltiples, envase, y la caja de regalo se puede completar automáticamente, ahorro de costes laborales.

No sólo te proporcionamos equipos, sino que también le brindamos soluciones integrales para ayudarlo a lanzar productos de alta calidad., Productos de azúcar de alto valor agregado en el mercado global y ganar la doble cosecha de clientes y boca a boca..