Cocción de precisión para resultados superiores

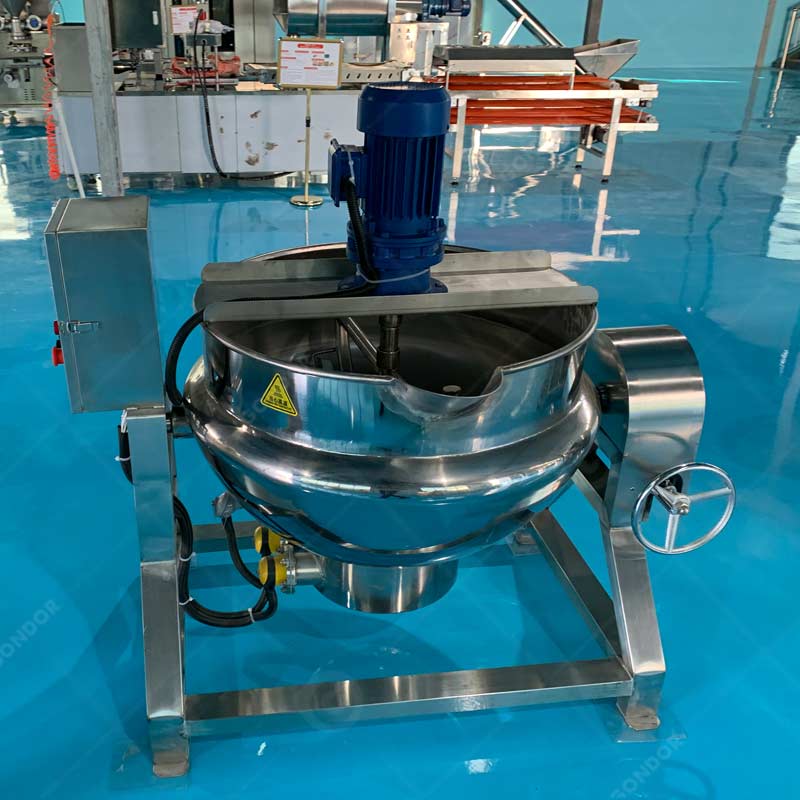

Gondor hervidor de vapor de doble camisa Se presenta como una herramienta esencial para la producción moderna de alimentos., Diseñado específicamente para hervir dulces con una consistencia excepcional.. Elaborado con materiales de alta calidad aptos para alimentos., Ofrece una resistencia superior a la corrosión y una distribución óptima del calor., Garantizar tanto la pureza del producto como la eficiencia operativa.. Esta base duradera la hace ideal para procesos de confitería exigentes..

Más allá de su robusta construcción, el hervidor integra un mecanismo de agitación avanzado, sistema de calefacción preciso, y controles intuitivos para crear un entorno de cocción perfectamente gestionado. Esta sinergia permite a los fabricantes producir de forma fiable desde delicados jarabes de azúcar hasta bases espesas y saladas., garantizando un sabor y una textura uniformes lote tras lote. Adecuado para fábricas de dulces., plantas alimenticias, y cocinas de gran tamaño, ofrece el control necesario para una producción superior.

|

Modelo |

Capacidad | Tamaño | Diámetro de la boca de la olla | Potencia de calefacción eléctrica | Potencia de calefacción de gas |

| GD-BYJKM-50 | 50l | 1300*750*900milímetros | 600milímetros | 12kilovatios |

0.75kilovatios |

|

GD-BYJKM-100 |

100l | 1400*850*900milímetros | 700milímetros | 18kilovatios | 1.1kilovatios |

| GD-BYJKM-200 | 200l | 1500*950*900milímetros | 800milímetros | 24kilovatios |

1.5kilovatios |

|

GD-BYJKM-300 |

300l | 1600*1050*900milímetros | 900milímetros | 24kilovatios | 1.5kilovatios |

| GD-BYJKM-400 | 400l | 1700*1150*900milímetros | 1000milímetros | 36kilovatios |

1.5kilovatios |

|

GD-BYJKM-500 |

500l | 1750*1250*950milímetros | 1100milímetros | 36kilovatios | 2.2kilovatios |

| GD-BYJKM-600 | 600l | 1850*1350*950milímetros | 1200milímetros | 48kilovatios | 2.2kilovatios |

Principales campos de la industria de servicios de la caldera de vapor con doble camisa

Se utiliza para cocinar varios platos., como guisar, sopa hirviendo, salsas hirviendo, etc.. También puede hacer delicias especiales., como base de olla caliente, salmuera, etc., para brindar sabores únicos a los restaurantes.

Procesamiento de diversos alimentos enlatados., condimentos, apretura, etc.. Adecuado para producción a gran escala., mejorar la eficiencia de la producción y reducir los costos de producción.

hervir jarabes, chocolates, etc.. para hacer varios dulces y pasteles especiales, agregar sabores únicos, mejorar la calidad y el grado del producto, y satisfacer las diferentes necesidades de los consumidores.

En el proceso farmacéutico, Se puede utilizar para hervir ungüentos de medicina china., decocciones, etc., que puede mejorar la eficacia de los medicamentos y garantizar la calidad y seguridad de los medicamentos.

El equipo se puede utilizar para hervir las materias primas de la pasta en productos químicos diarios, como la pasta de dientes, para alcanzar la temperatura y concentración adecuadas para garantizar la calidad y estabilidad de los productos..

Como pasta de miel, pasta de gelatina de piel de burro, etc., La temperatura y el tiempo de calentamiento se pueden ajustar según las diferentes necesidades de productos para el cuidado de la salud para satisfacer las diversas necesidades del mercado..

Características únicas de la tetera con chaqueta de vapor Gondor

Solución completa de integración de línea de producción de dulces

Para establecer un sistema integral línea de producción de gomitas, Este equipo se integra perfectamente con los siguientes componentes.:

- Crisol de azúcar: Predisuelve materias primas como el azúcar granulada.. Se conecta directamente a la olla de ebullición a través de tuberías para la transferencia automatizada de material..

- Sistema de dosificación de ingredientes: Agrega colorantes con precisión, aromas, y otros aditivos para garantizar recetas consistentes.

- Máquina depositadora de dulces: Recibe directamente jarabe de azúcar fundido para obtener precisión., moldura medida.

- Túnel de enfriamiento: Conectado aguas abajo para enfriar y fraguar rápidamente los caramelos moldeados..

- Máquina de embalaje: Interfaces con el túnel de enfriamiento para completar el envasado automatizado de dulces..

- Sistema de control inteligente: El panel de control centralizado permite el ajuste unificado de todos los parámetros de la línea, lograr una producción totalmente automatizada a partir de la fusión del azúcar, hirviendo, moldura, al embalaje.

Hervidor de vapor de doble chaqueta de alta calidad de Gondor – La primera opción para la fabricación de dulces

Nuestro hervidor de vapor de doble chaqueta es de excelente calidad.. El control preciso de la temperatura y el calentamiento uniforme garantizan una perfecta ebullición del azúcar.. Material de calidad alimentaria, seguro, higiénico y fácil de limpiar. Apto para dulces, pastelería y otras industrias. La ebullición eficiente te aporta riqueza. Elige Gondor ,Hervidor de vapor con doble camisa para comenzar tu dulce viaje profesional.