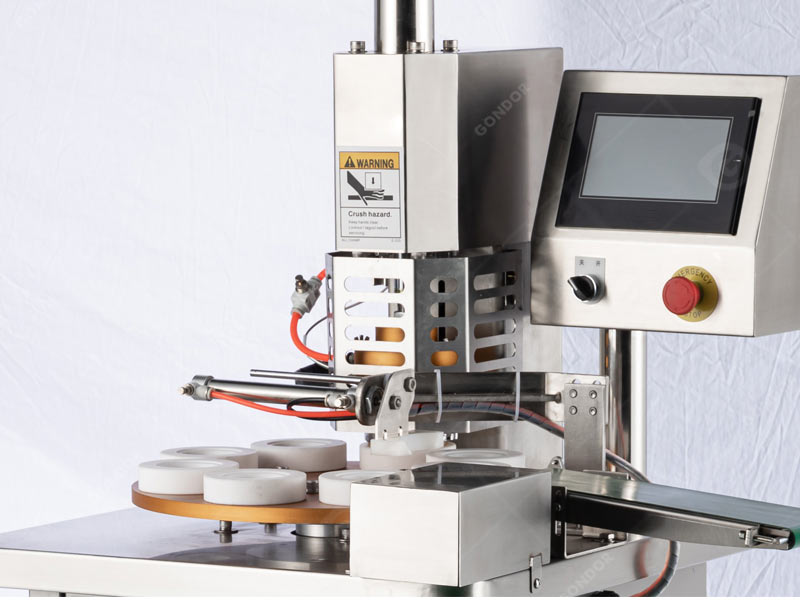

Máquina formadora de tarta de huevo Gondor

Máquina para fabricar tartas de huevo Es un equipo profesional de procesamiento de alimentos.. Puede hacer deliciosas cortezas de tarta de huevo de manera eficiente.. Además, El diseño neumático profesional garantiza el estándar de moldeo de la corteza de la tarta de huevo., con alta eficiencia. Se pueden utilizar diferentes moldes para hacer cortezas de tarta de huevo de diversas especificaciones y formas.. Además, Las cortezas de tarta de huevo elaboradas con este equipo tienen un grosor uniforme y un sabor crujiente..

La máquina para hacer tartas de huevo no solo ahorra mano de obra y costos de tiempo, pero también garantiza la calidad estable de la corteza de la tarta de huevo.. Ya sea una pequeña panadería o una gran planta procesadora de alimentos, La máquina para hacer tartas de huevo es un poderoso asistente para hacer tartas de huevo., brindando a la gente el delicioso disfrute de la tarta de huevo.

Máquina semiautomática de tarta de huevo Gondor

Máquina automática de tarta de huevo Gondor

Especificación de la máquina formadora de tarta de huevo

|

Nombre |

Máquina formadora de corteza de tarta de huevo | Rango de diámetro | 30-100milímetros |

| Modelo | GD-ETCF-E030 | Voltaje |

220V / 380V |

|

Fuerza |

2.5kilovatios | Tamaño | 1700milímetro*850m m*1300m m |

| Capacidad | Alrededor de 1500 piezas/h | Peso |

300kilos |

Alcance del mercado de aplicaciones de la máquina formadora de tartas de huevo Gondor

- La producción automatizada puede mejorar la eficiencia de la producción y la estabilidad de la calidad del producto., reducir los costos laborales, y satisfacer la gran demanda del mercado.

- Produce varias cortezas especiales de tarta de huevo., como agregar rellenos de diferentes sabores, utilizando fórmulas de masa especiales, etc., para conocer a los consumidores’ demanda de gustos diversificados.

- Se puede producir rápidamente una gran cantidad de masas de tarta de huevo para satisfacer las necesidades del cliente.. Además, las cortezas de tarta de huevo hechas por la máquina tienen una forma regular y un grosor uniforme.

- Algunas panaderías de alta gama o panaderías especializadas pueden lanzar sus propios productos exclusivos de tarta de huevo., como tartas de huevo creativas, tartas de huevo personalizadas, etc..

- El hotel utiliza este equipo para elaborar tartas de huevo de diferentes especificaciones y sabores., ahorro de mano de obra y costes de tiempo.

- Los departamentos de catering, como los restaurantes occidentales y los restaurantes chinos, pueden ofrecer tartas de huevo a los huéspedes como postre después de las comidas..

- Producir varios bocadillos., como galletas con masa de tarta de huevo, rollitos de masa de tarta de huevo, etc., y venderlos como bocadillos independientes.

- Combínelo con otros ingredientes para producir productos alimenticios innovadores., como pizza de tarta de huevo, pastel de tarta de huevo, etc., para conocer a los consumidores’ demanda de alimentos diversificados.

Ventajas excepcionales de la máquina para hacer tartas de huevo Gondor

Después del moldeado, la piel de la tarta de huevo es uniformemente gruesa y de tamaño uniforme, asegurando un sabor consistente y una apariencia exquisita, mejorar la calidad y el atractivo del producto.

Adopción de pantalla de control inteligente PLC, la interfaz es clara, la operación es conveniente, el uso es más sencillo, y se logra fácilmente un control preciso y una producción eficiente.

El cuerpo de acero inoxidable es resistente, durable, suave y fácil de limpiar, fácil de limpiar, mantener el equipo higiénico, y cumplir con los estándares de higiene del procesamiento de alimentos..

El reemplazo del molde es fácil, adecuado para varios estilos de producción, versátil, satisface diferentes necesidades del cliente, y amplía el espacio de mercado.

Producción totalmente automática, reducción de la operación manual, ahorro de costes laborales, mejorar la eficiencia de la producción, y lograr una producción estable a gran escala.

Máquina formadora de tarta de huevo Gondor – Un buen ayudante para hornear

Si quieres preparar fácilmente una deliciosa masa de tarta de huevo, La máquina para hacer tartas de huevo Gondor es su opción ideal! Es fácil de operar, eficiente y rapido, y puede hacer rápidamente una corteza de tarta de huevo uniforme y crujiente. Ya sea para que la panadería aumente la producción o para que la familia disfrute de la diversión., puede hacer el trabajo perfectamente. Elige la máquina de tartas de huevo Gondor para hacer deliciosas tartas de huevo al alcance de la mano. Únase a nosotros y creemos juntos un dulce momento de horneado.!