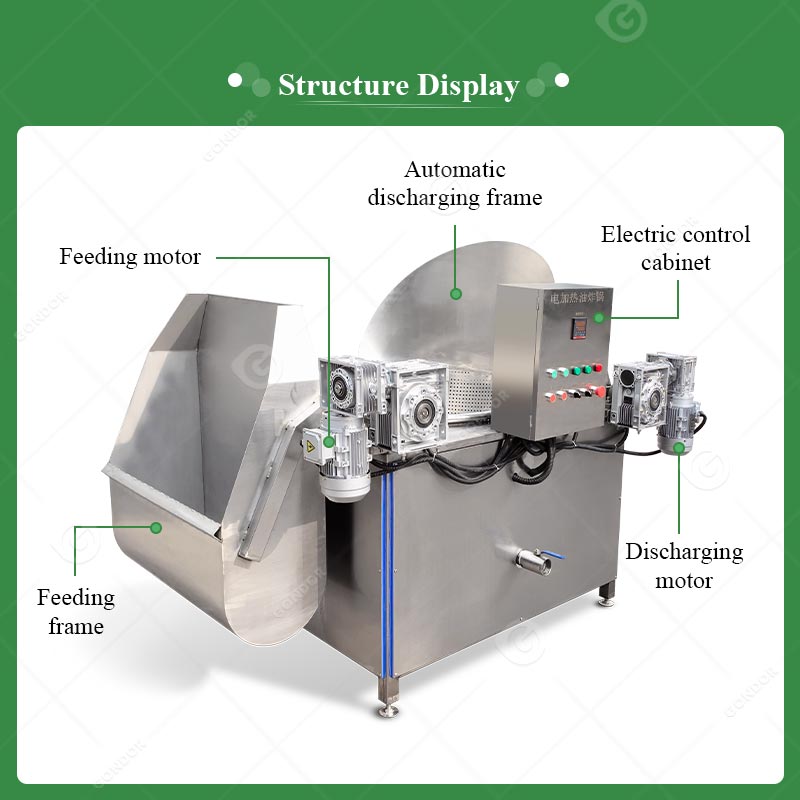

Un freidora redonda industrial Es un equipo de fritura eficiente especialmente diseñado para empresas procesadoras de alimentos.. El equipo principal está hecho de acero inoxidable SUS304 de calidad alimentaria., que tiene una excelente resistencia a la corrosión, seguridad, y estabilidad. Su innovadora estructura de agitación sincrónica de revolución y rotación garantiza que los ingredientes se calienten uniformemente y no se peguen., mejorando así eficazmente la calidad del producto y la eficiencia de producción.

Este equipo está equipado con un sistema inteligente de control de temperatura., que puede realizar un control preciso de la temperatura y una producción automática, evitar quemar ingredientes, y prolongar la vida útil de la grasa. La freidora industrial tiene una estructura compacta y puede equiparse con un sistema automático de carga y descarga., lo que puede ahorrar significativamente mano de obra y costos. Es una opción ideal para que las empresas procesadoras de alimentos mejoren su nivel de automatización..

| Modelo | Fuerza | Voltaje | Diámetro de la cesta para freír | Tamaño de la máquina |

| GD-800 | 36kilovatios | 380V 50 Hz | 800 | 1050*1000*1700 |

| GD-1000 | 48kilovatios | 380V 50 Hz | 1000 | 1250*1200*1700 |

| GD-1200 | 60kilovatios | 380V 50 Hz | 1200 | 1450*1400*1700 |

| GD-1500 | 78kilovatios | 380V 50 Hz | 1500 | 1750*1700*1700 |

Rango de mercado de aplicaciones de la freidora industrial

La freidora industrial es adecuada para una variedad de industrias de procesamiento de alimentos y puede cumplir con los requisitos de la producción continua de fritura.:

- Papas fritas/Papas fritas

- Frutos secos como el maní

- Productos Cárnicos Productos Cárnicos

- Productos acuáticos

- Rollitos de primavera/bocadillos

- Procesamiento de refrigerios de varios refrigerios

Excelentes ventajas de rendimiento de la freidora industrial

¿Por qué elegir nuestra freidora redonda??

- Diseño razonable, estructura compacta, y ahorro de tierra.

- Alto grado de automatización, reduciendo los costos laborales.

- Sin humo de aceite, sin olor a comida.

- La calidad de la fritura es estable., y se mejora la calidad del producto.

- Es adecuado para una variedad de alimentos y tiene una gran expansibilidad..

- Seguro y confiable, fácil de mantener.

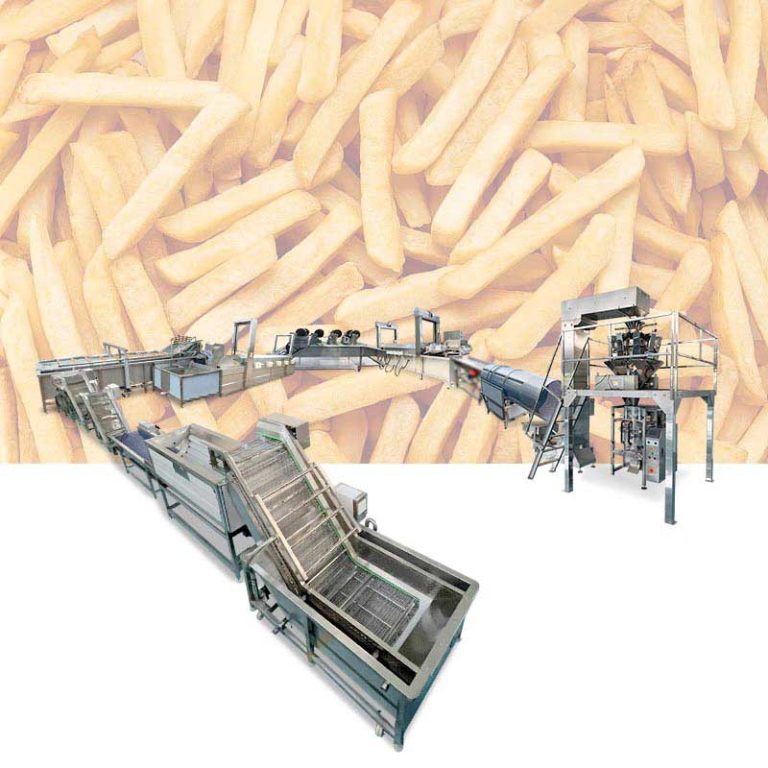

Equipo de soporte recomendado

Para satisfacer las necesidades del procesamiento automático y a gran escala de alimentos., También proporcionamos una variedad de equipos de soporte., que puede formar una línea de producción completa con la freidora:

-

- Lavadora de burbujas

- Máquina desengrasante

- Máquina para sazonar patatas fritas

- Máquina de embalaje