Máquina de llenado de líquidos Gondor

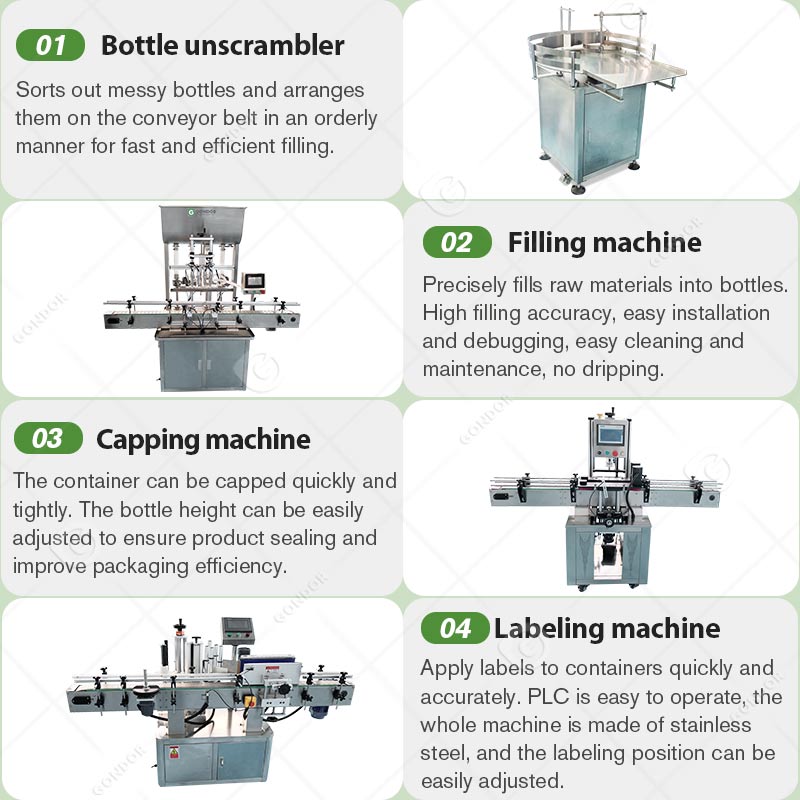

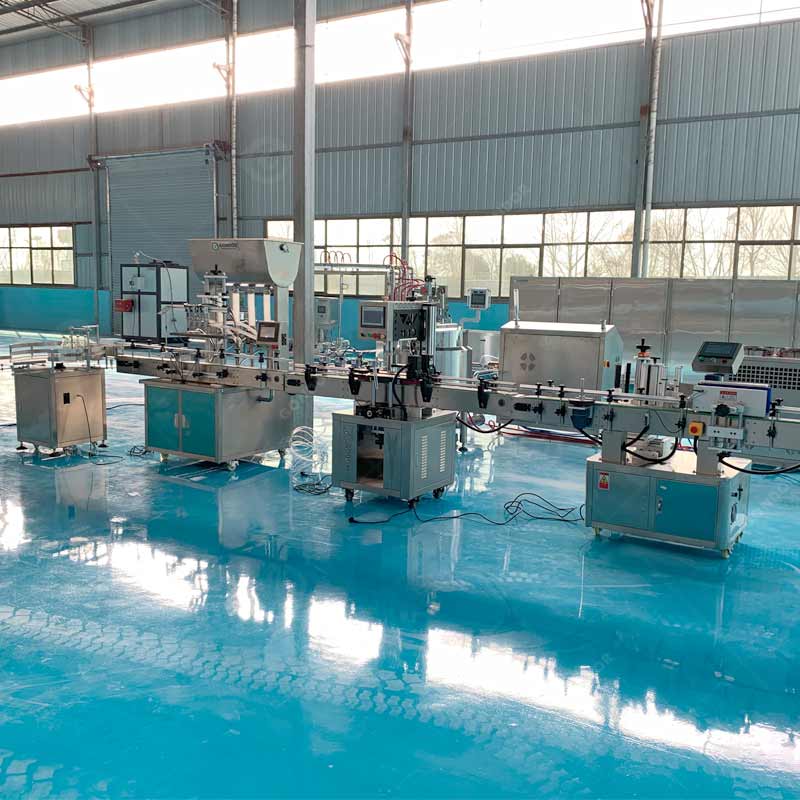

Este línea de llenado de líquidos integra clasificación automática de botellas, llenado preciso, sellado de alta velocidad, y etiquetado inteligente, formando un sistema de embalaje automático integral. Toda la línea adopta un sistema de control inteligente PLC., combinado con un módulo de llenado de alta precisión, que puede controlar el error de llenado de cada botella de líquido dentro 1%, satisfaciendo así las necesidades de alta velocidad, a gran escala, y producción de precisión. Al mismo tiempo, El equipo está hecho de calidad alimentaria. 304 acero inoxidable, que se ajusta a las normas sanitarias internacionales, y no sólo es estable en funcionamiento sino también conveniente en mantenimiento, haciéndolo muy adecuado para la industria moderna de envasado de líquidos.

Especificación de la línea de producción de llenado de líquidos

| Productos | posicionador de botellas | Máquina de llenado | Máquina taponadora | Máquina etiquetadora |

| Voltaje | 220v | |||

| Fuerza | 120w | 500w | 0.8kilovatios | 1.5kilovatios |

| Producir | / | 5-60 botellas/min | 30-60 piezas/min | 20-200 piezas/min |

| Peso | 120kilos | 800kilos | 550kilos | 270kilos |

| Tamaño(milímetros) | 1250*1250*1350 | 2000*1250*1600 | 2000*850*1800 | 1220*1250*1470 |

| Diámetro de la botella | / | / | ∅35-∅140mm | ∅30-∅180mm |

| Altura de la etiqueta | / | / | / | 15-150milímetros |

| Longitud de la etiqueta | / | / | / | 25-300milímetros |

| Diámetro de la tapa de la botella | / | / | 20-100milímetros | / |

Aplicaciones industriales de la línea de producción de llenado de líquidos

Esta línea de producción de llenado es especialmente adecuada para el envasado de diversos productos líquidos., cubriendo una amplia gama de industrias, incluyendo pero no limitado a:

Excelente rendimiento de la línea de producción de líquidos

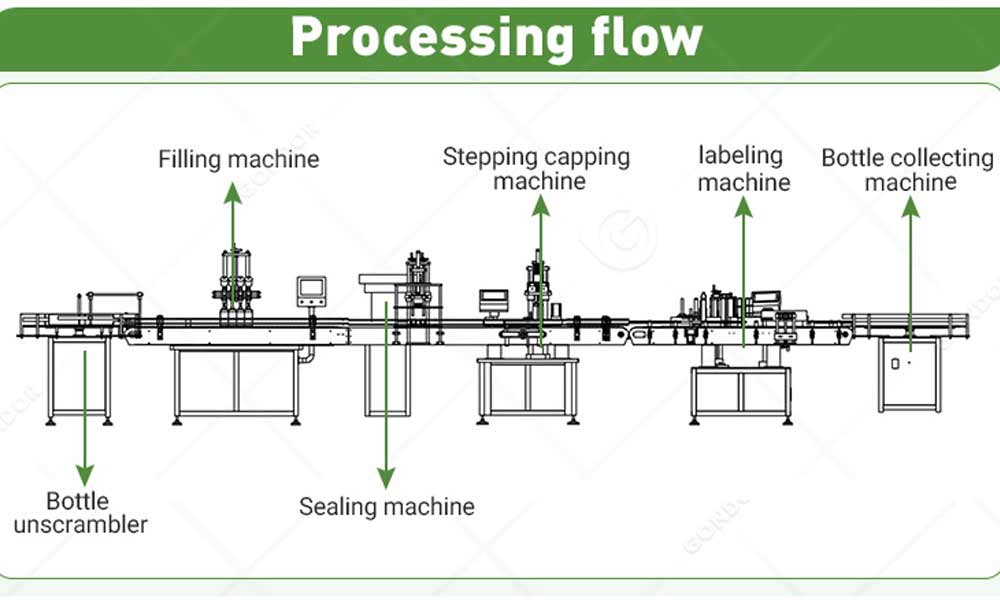

Flujo de trabajo de la línea de llenado de líquidos

Las máquinas llenadoras de líquidos se basan en control zonificado y seguimiento sincrónico.. La línea de producción está programada centralmente mediante un PLC.. Sensores en cada estación (fotoeléctrico, interruptores de proximidad, etc.) Detecta la posición del contenedor y envía las señales al sistema de control., que luego dirige los mecanismos correspondientes (como cabezales de llenado y cabezales taponadores) para completar acciones precisas en el momento de movimiento o quietud.

Un flujo de trabajo típico es el siguiente (tomando como ejemplo las botellas de bebidas):

Suministro de botellas vacías: botellas vacias, después de ser despaletizado o salir de la máquina de soplado anterior, se introducen en la línea de producción en un solo, columna espaciada uniformemente por una cinta transportadora.

Limpieza de botellas vacías (si es necesario): Los biberones se enjuagan con aire purificado o agua esterilizada en una estación de enjuague invertida con el cuello de la botella hacia abajo..

Alineación y Relleno: La cinta transportadora entrega las botellas a la mesa giratoria o a la estación de llenado lineal de la máquina llenadora., donde el cuello de la botella está colocado exactamente debajo de la válvula de llenado.

Sellado Inmediato: Las botellas llenas se envían inmediatamente a la unidad de sellado., donde el cabezal taponador agarra la tapa y la aprieta, o una máquina taponadora presiona la tapa de corona.

Sellado y etiquetado secundario: Esto puede implicar sellar con papel de aluminio., sellado de película termorretráctil, etc.. Luego, el producto ingresa a la máquina etiquetadora para una colocación precisa de la etiqueta principal..

Inspección y marcado en línea: Una controladora de peso retira productos con un volumen de llenado insuficiente; un sistema de inspección por visión comprueba el nivel del líquido, caza de focas, y calidad del etiquetado; una impresora de inyección de tinta imprime la fecha de producción y el número de lote en la botella o etiqueta.

Salida del producto terminado: Los productos calificados se recogen mediante una cinta transportadora y una empacadora de cajas los empaca automáticamente en cajas de cartón o jaulas.. Finalmente, pueden ser apilados en pilas paletizadas mediante un robot paletizador, en espera de almacenamiento.

Recomendación de equipo a juego

Para construir una más eficiente, taller de embalaje totalmente automático, También puedes considerar usar el siguiente equipo.:

- Sellador de cartón

- Impresora de inyección de tinta

- Máquina de túnel termorretráctil

- Sistema transportador