Gondor Pasta Production Lines

En la era actual de la búsqueda de la calidad y el consumo personalizado, Los pequeños talleres de alimentos y los empresarios buscan constantemente equipos de producción que puedan equilibrar la tecnología., eficiencia, y gusto. Nuestro nuevo pequeña línea de producción de pasta nació para este propósito. Combina la tecnología tradicional italiana de fabricación de fideos con la moderna tecnología de automatización., facilitando que su taller reproduzca el auténtico sabor italiano y cree una marca de comida local competitiva.

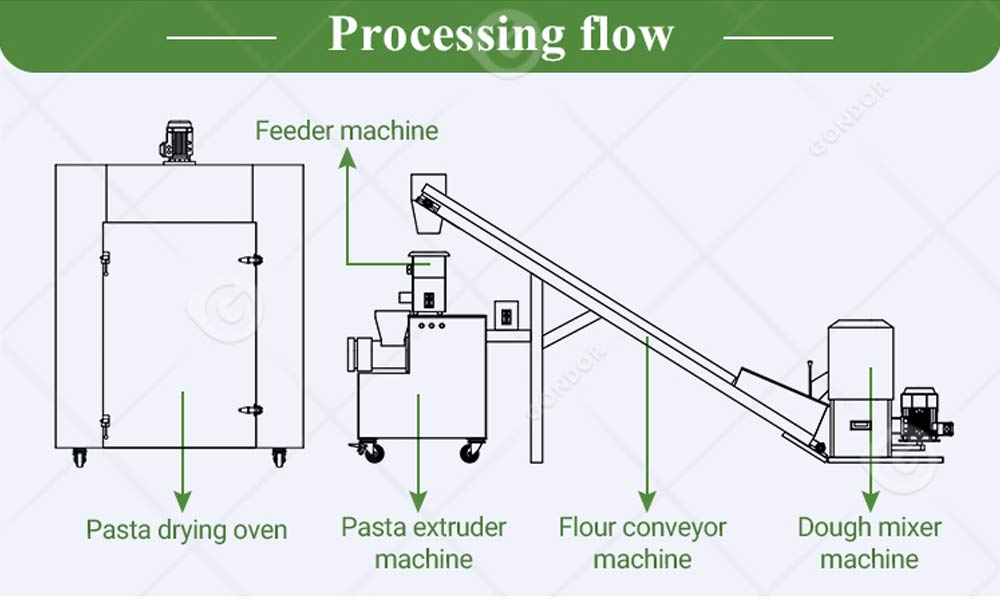

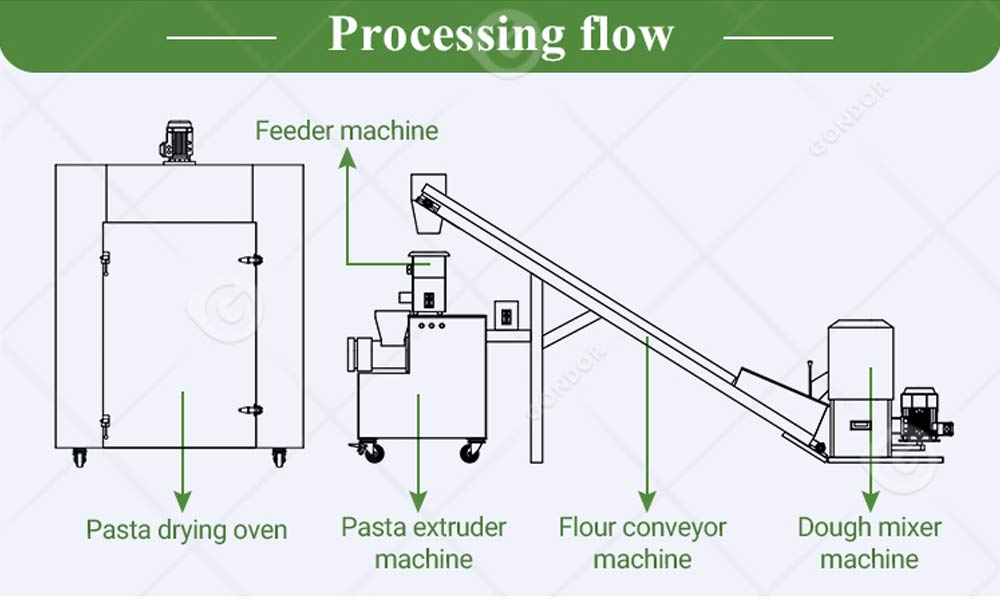

Esta línea de producción de macarrones semiautomática está especialmente diseñada para pequeñas y medianas empresas alimentarias., cocinas centrales, y talleres de startups. Toda la línea consta de una amasadora., transportador de harina, sistema de alimentación, extrusora de macarrones, y secadora. El equipo presenta una estructura compacta., pequeña huella, y fácil operación, Admite varios moldes y capacidades de producción personalizables para lograr una producción totalmente automatizada desde las materias primas hasta los productos terminados..

Small Pasta Production Line Specification

| Nombre de la máquina |

Voltaje |

Fuerza |

Material |

Tamaño |

| Máquina mezcladora de masa |

380V |

3kilovatios |

Acero inoxidable |

900*550*1000milímetros |

| Máquina transportadora de harina |

220V |

0.35kilovatios |

2800*750*650milímetros |

| Máquina extrusora de pasta |

380V |

5.5kilovatios |

1100*650*1200milímetros |

| Horno de secado de pasta |

380V |

12kilovatios |

1400*1250:2350milímetros |

| Máquina alimentadora |

220V |

0.3kilovatios |

650*420*450milímetros |

Mercado objetivo de la línea de producción de pasta de corte largo

La línea de producción de pasta de corte largo es una opción ideal para los pequeños y medianos fabricantes de alimentos de todo el mundo., especialmente para los siguientes grupos de clientes:

Ayudar a las marcas a diferenciar su sabor italiano en el mercado local..

Talleres de comida para startups

Un esquema de equipamiento ideal con baja inversión y alto retorno..

Productores de alimentos especializados

Se utiliza para desarrollar productos de pasta corta con formas y sabores innovadores..

Abastecimiento & Restaurantes

.

Bajo la creciente tendencia de los consumidores’ búsqueda de la salud, textura hecha a mano, y sabor fresco, Esta pequeña línea de producción ayudará a las empresas a aprovechar las oportunidades del mercado..

Características principales del equipo de la línea de producción de pasta corta

Mezclador de masa

Se adopta una estructura de acero inoxidable., Y el tiempo y la velocidad de agitación se pueden configurar libremente para garantizar que la masa sea uniforme y elástica.. Equipado con ventana visual y sistema automático de protección de seguridad., Se tienen en cuenta tanto la seguridad como la calidad..

Transportador de harina

El sistema de transporte completamente cerrado evita la contaminación secundaria, Y la longitud de transporte se puede personalizar., reduciendo eficazmente el trabajo de manipulación manual. Ahorro de energía, eficiente, continuo, y estable.

Alimentador de precisión

- Spiral feeding design realizes high-precision quantitative feeding and ensures a stable and smooth extrusion process.

- El control del motor independiente puede ajustar de manera flexible la velocidad de alimentación según las diferentes características de la masa..

Extrusora de macarrones

- El equipo principal de toda la línea puede ser una extrusora de uno o dos cabezales..

- Se puede producir fácilmente una variedad de pasta corta cambiando los moldes., incluyendo macarrones, Penne, Fusilli, mariposa, Conchas, etcétera.

- El cabezal de la máquina está equipado con un cortador giratorio., que puede ajustar automáticamente la longitud y la velocidad de corte para lograr un corte preciso, forma completa, y superficie lisa.

secadora

- A multi-layer circulating air system can control temperature, humedad, y el caudal de aire de forma independiente.

- Realice el proceso de secado lento a baja temperatura., Mantener la estructura interna y el sabor de la pasta al máximo., y evitar grietas y deformaciones.

- Los macarrones secos se pueden envasar directamente o pasar al proceso de enfriamiento posterior..

Ventajas únicas de una pequeña línea de producción de pasta

Diseño modularCapacidad personalizableOpciones de moldes múltiplesConformado rápido & Salida estableSoporte profesional:

Se puede ampliar de forma flexible según los requisitos de producción..

De 50 kg/h a 300 kg/h, adecuado para producción a diferentes escalas.

Apoyar el desarrollo de formas personalizadas para satisfacer las necesidades de productos creativos..

Alta eficiencia y alta consistencia.

Proporcionar instalación y depuración., formula training, y servicio postventa.

Ayuda a crear un auténtico sabor italiano

Si está planeando un proyecto completo de procesamiento de pasta, También proporcionamos una variedad de equipos de soporte.:

Bienvenido a contactarnos para una solución completa y cotización.. Deje que la pequeña línea de producción de macarrones sea el primer paso para crear el auténtico sabor italiano y expandir el mercado global.!