Máquinas trilladoras de maíz dulce fresco Gondor

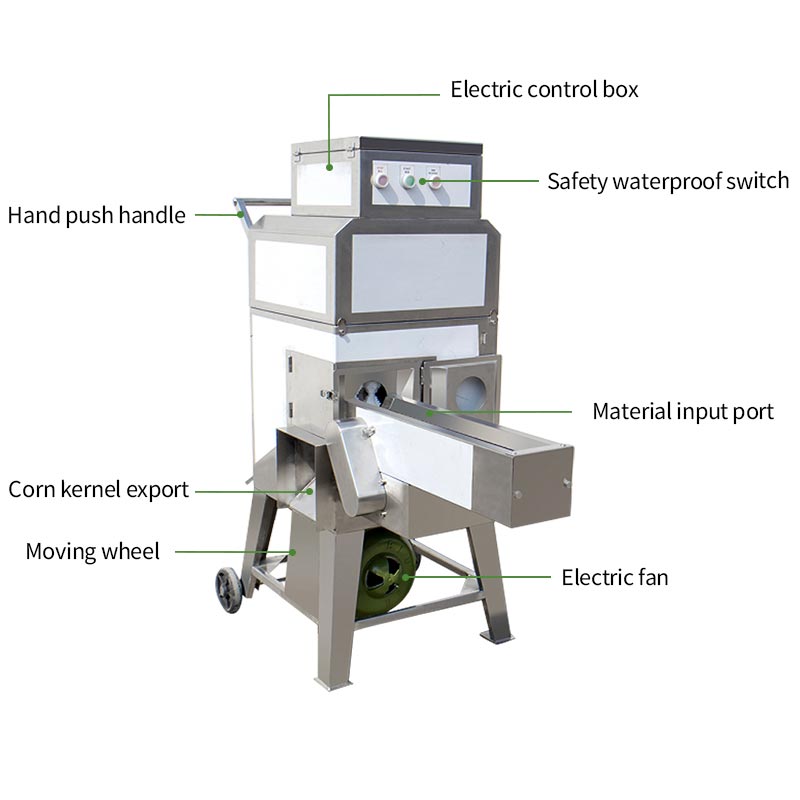

Máquina desgranadora y trilladora de maíz dulce y fresco es un dispositivo altamente eficiente diseñado específicamente para procesar todo tipo de maíz. Además, es muy utilizado en restaurantes, escuelas, comedores, plantas procesadoras de alimentos, y otros lugares. Además, Puede ajustar la profundidad de trilla según el tamaño de la mazorca de maíz., asegurando que los granos de maíz permanezcan intactos. El equipo no solo es fácil de operar sino también de rendimiento estable., con una tasa de purificación de trilla de hasta 99%, garantizando así un entorno de producción limpio e higiénico.

La máquina desgranadora de maíz fresco está equipada con cuchillos duraderos., además, ocupa un área pequeña, haciéndolo adecuado para su uso en una variedad de escenarios. Además, es fácil de desmontar, seguro, y confiable, mejorando así en gran medida la eficiencia de la trilla de maíz, lo que lo convierte en una opción ideal para el procesamiento de maíz..

Especificación de la máquina trilladora de maíz fresco

| Modelo | GD-168 | GD-168L |

| Capacidad | 400-500kg/hora | 500-600kg/hora |

| Tamaño | 65*60*125centímetro | 125*60*125centímetro |

| Peso | 90kilos | 100kilos |

| Voltaje | 110v/220v/380v | 110v/220v/380v |

Principales campos aplicables de la máquina trilladora de maíz dulce Gondor

Como restaurantes, hoteles, etc., utilizado para procesar maíz fresco.

Proporcionar soluciones eficientes para el procesamiento de maíz a gran escala..

Mejorar la eficiencia del procesamiento de maíz en los comedores..

Se utiliza para la trilla de maíz a gran escala para satisfacer las necesidades de producción..

Utilizado para la trilla de maíz a gran escala durante la temporada de cosecha..

Ayudar a desarrollar nuevos productos de maíz o tecnologías de procesamiento..

Proporcionar trilla de maíz en sitio a proveedores o clientes..

Usos comunes de la trilladora de maíz dulce

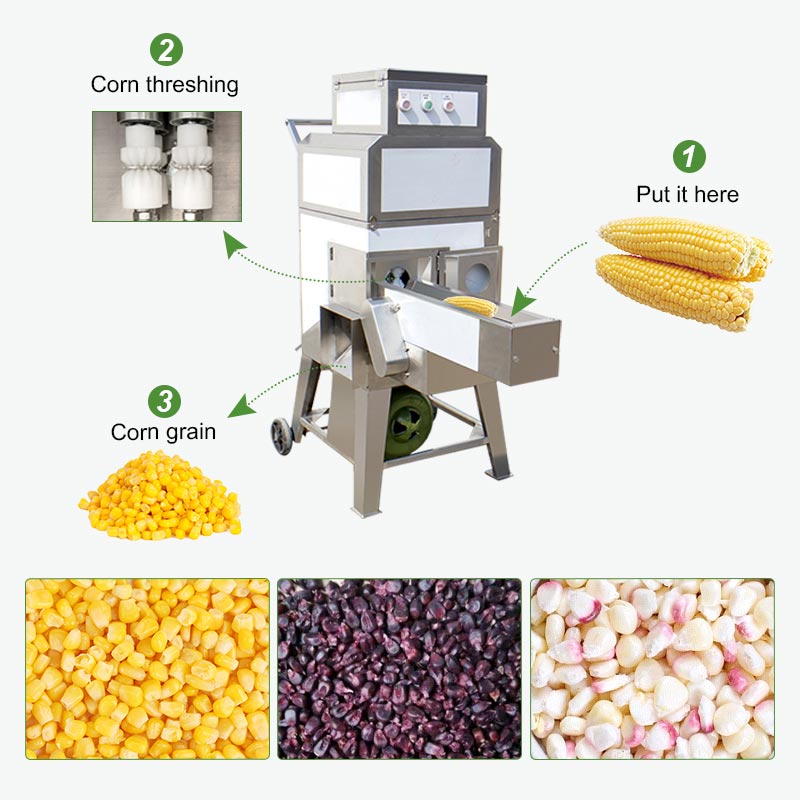

La máquina trilladora de maíz fresco utiliza una combinación de rodillos de cuchillas giratorias de acero inoxidable., limitadores elásticos, y alimentación direccional a “cortar” en vez de “lágrima” mazorcas de maíz frescas con un contenido de humedad superior a 60%, asegurando un corte limpio, sin granos rotos, y sin pérdida de savia. Por lo tanto, tiene muchas aplicaciones.

- Granos de maíz dulce congelados: Inmediatamente blanqueados y congelados rápidamente IQF después de la trilla., abasteciendo a restaurantes y supermercados durante todo el año.

- Maíz enlatado/tazas listas para comer: Conectado al llenado, caza de focas, y líneas de esterilización para producir granos enteros, pasta, o crema de maíz.

- Jugo y bebidas de maíz.: Los granos enteros sin roturas facilitan el posterior exprimido., hidrólisis enzimática, y fermentación.

- Empresas de preparación de comidas.: Utilizado en ensaladas, ingredientes para pizza, e ingredientes de comida para bebés.

- Propagación de semillas: El daño mínimo durante el corte del grano garantiza la viabilidad del germen, facilitando el posterior secado y recubrimiento.

Importantes ventajas de trabajo de la máquina trilladora de maíz dulce Gondor

Trilladora de maíz dulce Gondor – Ayuda al procesamiento eficiente del maíz

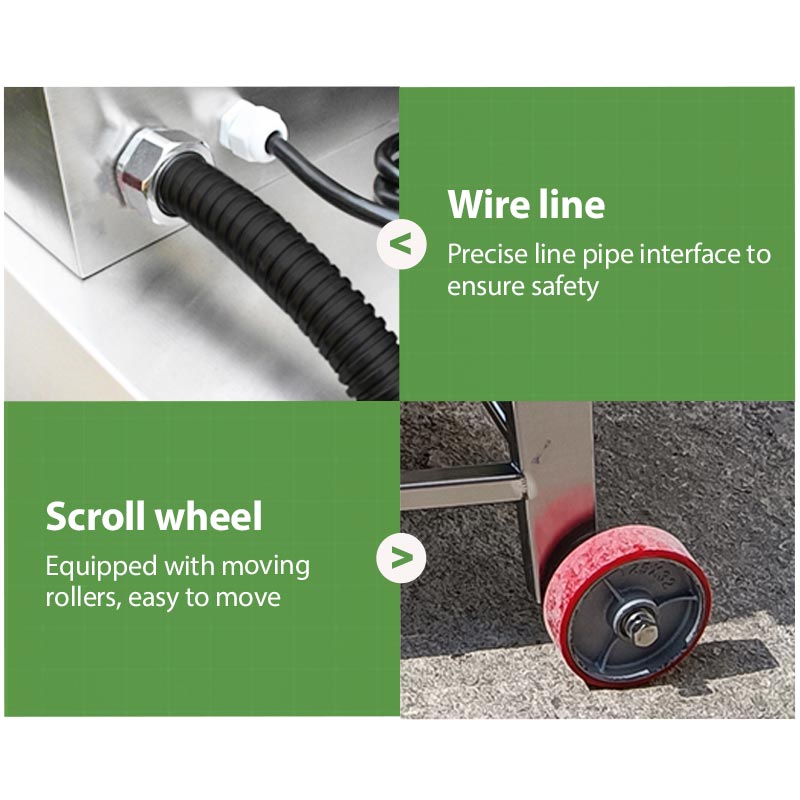

La máquina desgranadora y trilladora de maíz fresco dulce Gondor es una eficiente, durable, y equipos de procesamiento de maíz flexibles que están diseñados específicamente para satisfacer diversas necesidades de trilla de maíz.. Utiliza cortadores de acero inoxidable., que no sólo tienen una resistencia al desgaste extremadamente alta sino también una excelente adaptabilidad, haciéndolos adecuados para su uso en ambientes húmedos. Además, su innovador diseño del puerto de descarga mejora significativamente la velocidad y el rendimiento de trilla, haciéndolo ideal para escenarios de procesamiento a gran escala. Además, está equipado con rodillos móviles para un movimiento cómodo y flexible, asegurando así la comodidad, seguro, y operación confiable. Además, la tasa de rotura del grano de maíz es baja, mantener la integridad del producto. Por lo tanto, envíe una consulta ahora para conocer más detalles del producto, Ordene este equipo de procesamiento de maíz ideal, y, en última instancia, mejorar la eficiencia de la producción.!