Introducción a la máquina freidora al vacío Gondor

freidora al vacio es un sistema avanzado de procesamiento de alimentos que utiliza tecnología de vacío a baja temperatura para producir bocadillos fritos de alta calidad.. Operado a través de una interfaz de pantalla táctil intuitiva con control PLC automatizado, mantiene la temperatura precisa (80-120°C) y condiciones de presión durante todo el proceso de fritura.

Este innovador equipo reduce significativamente la absorción de aceite por 30-50% preservando los colores naturales, sabores, y nutrientes que a menudo se pierden en la fritura convencional. Ideal para producir frutas fritas premium, verduras, y refrigerios especiales con valor nutricional mejorado y características sensoriales superiores.

Freidora al vacío de alto rendimiento Gondor

Como fábrica especializada en el campo de la maquinaria alimentaria., Entendemos profundamente las demandas principales de las empresas al seleccionar equipos, no solo para asegurar la mejor máquina freidora al vacío sino también para equilibrar la racionalidad del precio de la máquina freidora al vacío., y lo más importante, para garantizar que el equipo cumpla con los requisitos de uso de alta intensidad de escenarios comerciales.

Nuestras series de máquinas freidoras al vacío comerciales cuidadosamente seleccionadas están hechas de 304 Acero inoxidable con un sistema de vacío estable., permitiendo un control preciso del entorno de procesamiento a baja temperatura entre 80 y 120 ℃. Adecuado para procesar diversos ingredientes como frutas., verduras, y carnes, Estas máquinas tienen un precio razonable y pueden satisfacer las diferentes necesidades de capacidad de producción de empresas que van desde tiendas nuevas hasta fábricas de alimentos a gran escala..

Modelos de freidora al vacío Gondor

Nuestra fábrica ofrece varios modelos de freidoras al vacío., junto con una garantía de un año y un completo servicio posventa, garantizando que no sólo pueda elegir equipos de alta calidad con un rendimiento superior, sino también disfrutar de una experiencia de compra asequible.

| Modelo | Modelo experimental | GD-VFFM-50 | GD-VFFM-1100 | GD-VFFM-1200 | GD-VFFM-1300 |

| Cantidad de material del marco | 2 | 2 | 2 | 2 | 2 |

| Tasa de vacantes laborales | -0.092~-0.098MPA | -0.092~-0.098MPA | -0.092~-0.098MPA | -0.092~-0.098MPA | -0.092~-0.098MPA |

| Temperatura de trabajo | 80~ 120 ℃ | 80~ 120 ℃ | 80~ 120 ℃ | 80~ 120 ℃ | 80~ 120 ℃ |

| Potencia de la bomba de vacío | 5.5kilovatios | 11kilovatios/7.5kw | 11kilovatios | 11+3kilovatios/11kw | 15+4kilovatios/15kw |

| Modo de calefacción | Electricidad/Vapor | Vapor | |||

| Volumen | 14l | 86l | 255l | 430l | 630l |

| Cargando material (Papas fritas) | 5-6kg/tiempo | 30-50kg/tiempo | 80-100kg/tiempo | 180-200kg/tiempo | 260-300kg/tiempo |

| Potencia Total Instalada / Potencia real | 31kilovatios/18.25kw | 21P/P14 | 21P/P14 | 25P/P18 | 28P/P22 |

| Dimensión | 1600*2000*2000milímetros | 2300*2100*2600milímetros | 3000*3000*3090milímetros | 3400*3400*3230milímetros | 3930*3670*3720milímetros |

Detalles de la freidora al vacío Gondor

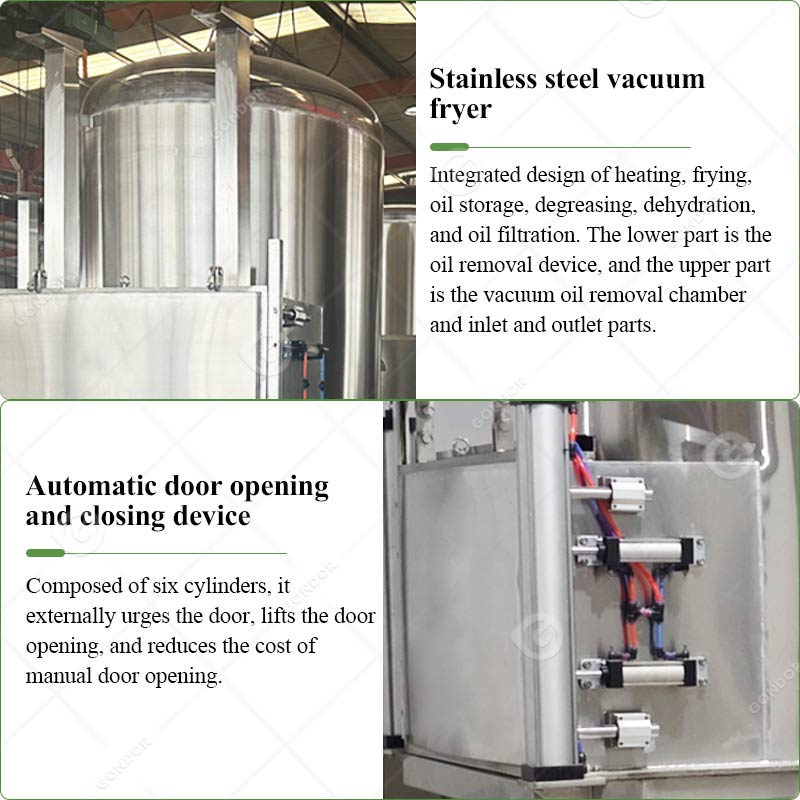

Esta freidora al vacío de acero inoxidable presenta un diseño integrado que abarca procesos de calentamiento y fritura.. Incluye un dispositivo de eliminación de aceite en la parte inferior y una cámara de desengrase al vacío y componentes de alimentación/descarga en la parte superior.. Su dispositivo de apertura y cierre automático de puertas de seis cilindros reduce los costes laborales.

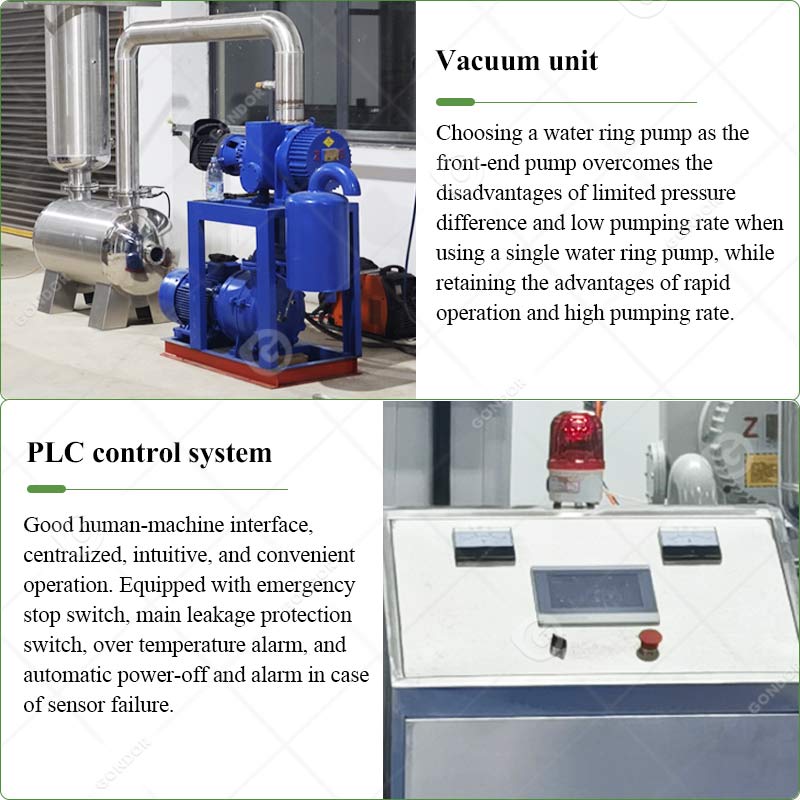

El sistema de vacío utiliza una bomba de anillo de agua como bomba forestal., Equilibrando una alta velocidad de bombeo con un rendimiento estable.. El sistema de control PLC no solo cuenta con una interfaz intuitiva y fácil de usar, sino que también cuenta con múltiples dispositivos de seguridad, como parada de emergencia y protección contra fugas.. Las alarmas de sobretemperatura y el apagado automático en caso de mal funcionamiento del sensor garantizan un funcionamiento seguro.

Aplicación de la máquina freidora al vacío Gondor

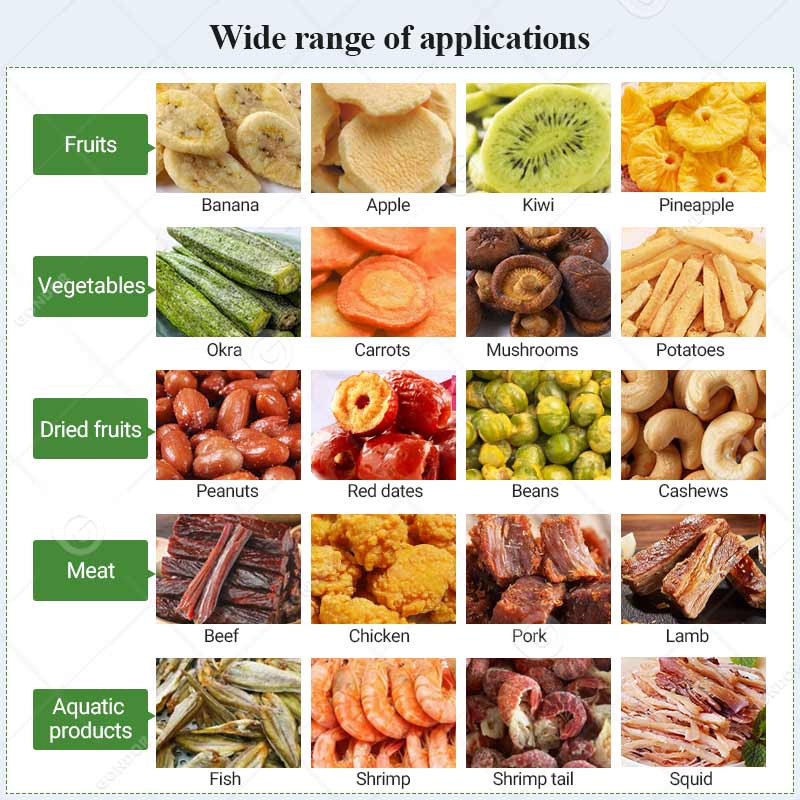

La freidora al vacío es adecuada para plantas procesadoras de alimentos., fabricantes de snacks, productores de alimentos saludables, cocinas centrales de restaurante, empresas procesadoras de productos agrícolas, y r&laboratorios D.

Una freidora al vacío puede procesar varios productos., incluyendo frutas (chips de manzana, chips de plátano, chips de mango), verduras (chips de zanahoria, chips de calabaza, papas fritas), carnes (chips de pollo, pieles de pescado), nueces (miseria, almendras), y bocadillos especiales (pasteles de arroz crujientes, rollitos de primavera de plátano). Admite perfiles de sabor tanto dulce como salado con un contenido de aceite reducido en 30-50% en comparación con la fritura tradicional.

Características de la freidora al vacío Gondor

Equipo de soporte recomendado

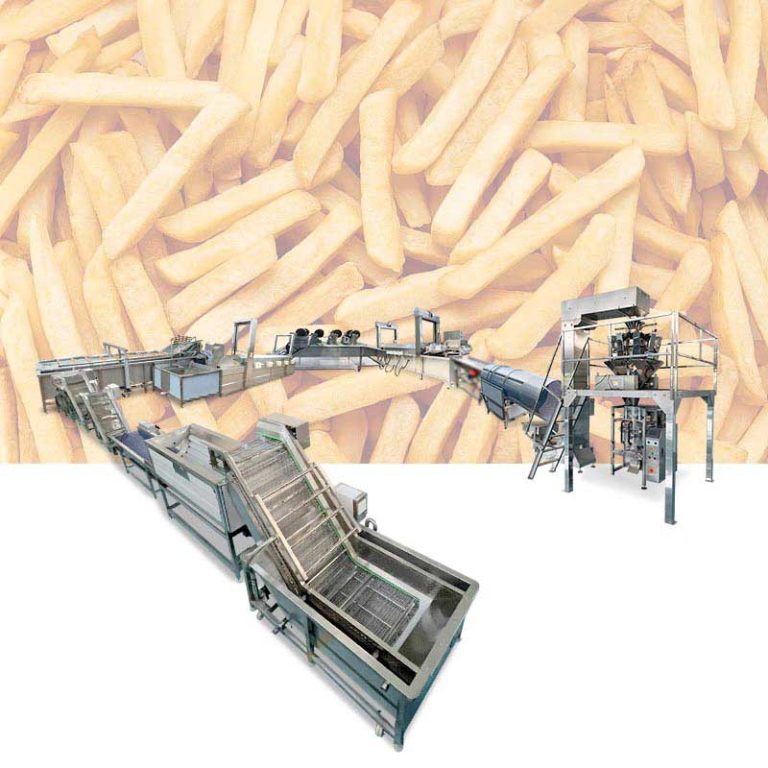

Para crear una solución integrada de fritura de alimentos más eficiente, el siguiente equipo se puede utilizar en conjunto:

- Máquina de limpieza de burbujas: Elimina a fondo las impurezas de la superficie de los alimentos., limpieza profunda mientras protege la integridad de los ingredientes, Sentar una base higiénica sólida para freír..

- Máquina marchitadora: La esterilización suave preserva los nutrientes y el sabor de los alimentos., Ampliar eficazmente la vida útil del producto y satisfacer las necesidades de manipulación segura de diversos alimentos..

- Máquina envasadora de almohadas: Automatiza la medición, caza de focas, y cortando, producir envases estéticamente agradables y seguros, Facilitar el envasado estandarizado y a gran escala de alimentos fritos..