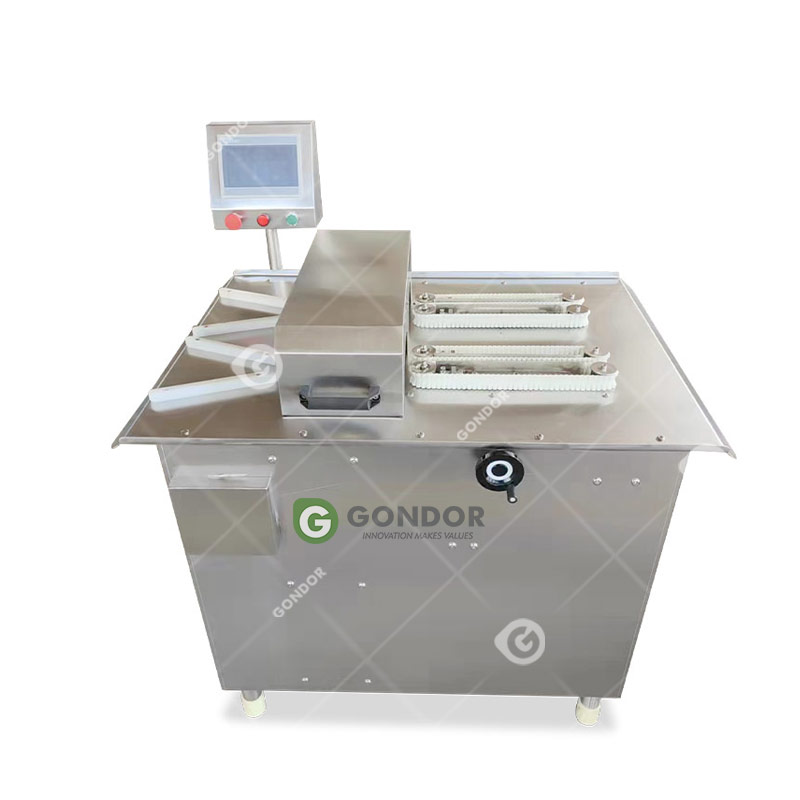

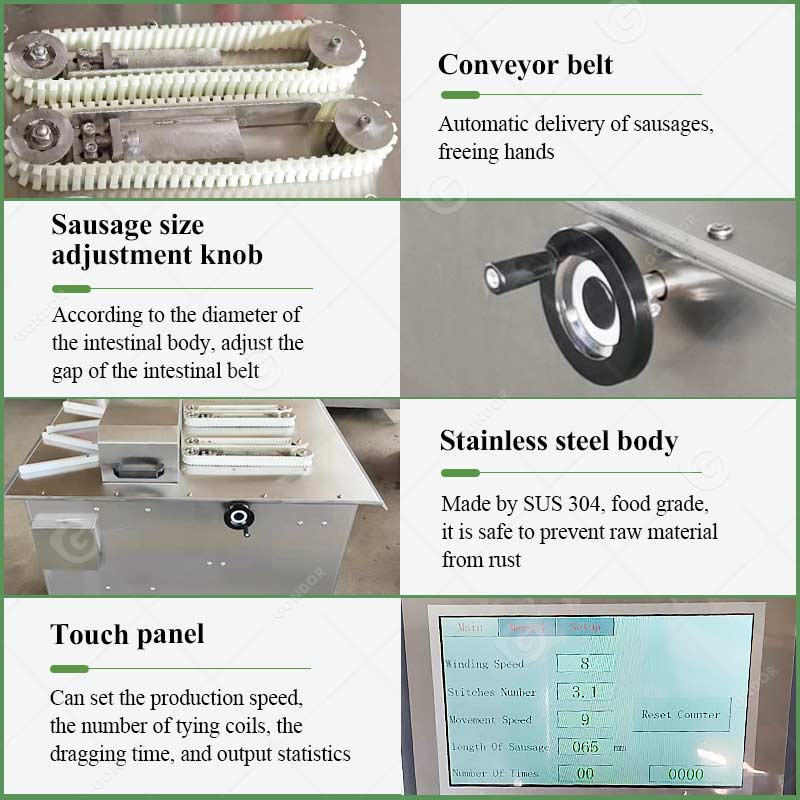

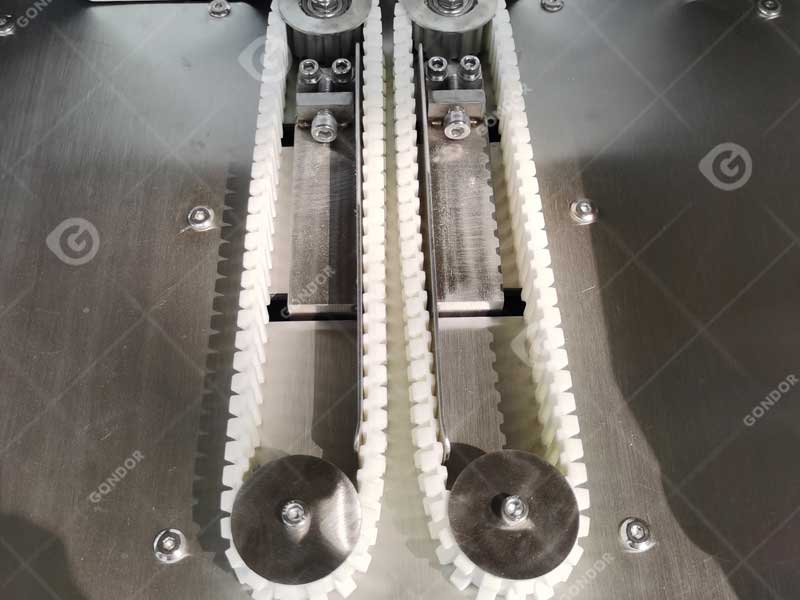

Mesin pengikat sosis elektrik otomatis adalah peralatan profesional yang berperan penting dalam proses pembuatan sosis. Sistem kendalinya terdiri dari layar sentuh dan sistem kendali servo. Lebih-lebih lagi, peralatan memiliki dua mode produksi: manual dan otomatis terus menerus. Efisiensi produksi lebih tinggi dalam mode kontinu otomatis. Di samping itu, mesin pengikat sosis listrik memiliki keunggulan pengoperasian yang mudah, efisiensi tinggi, dan efek pengikatan kawat yang bagus. Sistem kontrol layar sentuh yang intuitif dapat mengatur banyak parameter dan juga dapat melakukan statistik produksi. Lebih-lebih lagi, struktur mekanik mengadopsi pemrosesan CNC, dengan presisi tinggi, fungsi tahan air yang baik, dan hampir tidak ada pemeliharaan, yang merupakan pilihan terbaik untuk perusahaan makanan kecil dan menengah.

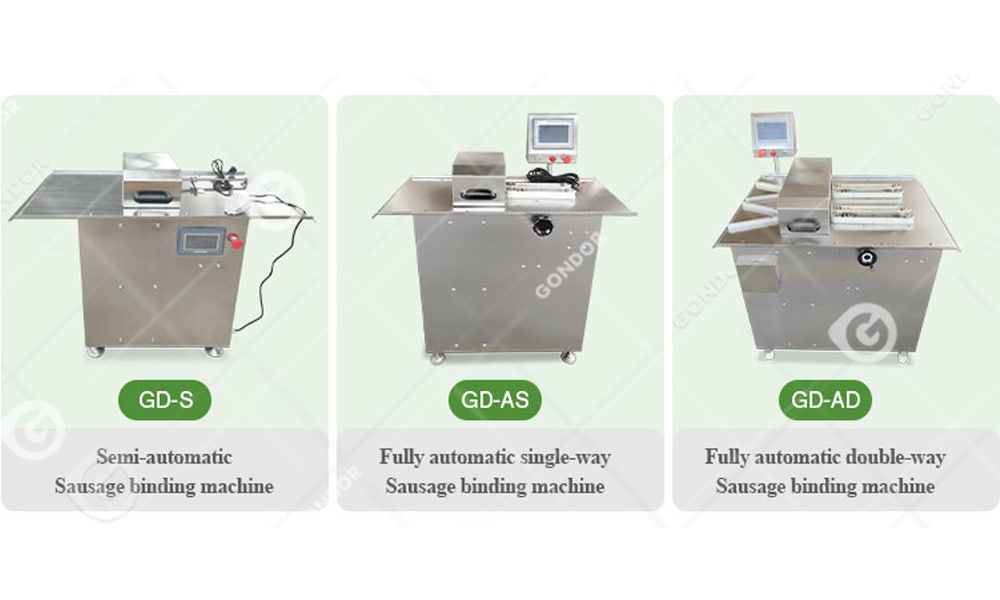

| Model | GD-S | GD-AS | GD-AD |

| Kekuatan | 1.5kw | 2kw | 3.5kw |

| Produktivitas (bagian/menit) | 10-100 dapat disesuaikan | 10-100 dapat disesuaikan | 10-450 dapat disesuaikan |

| Ukuran casing tunggal (mm) | 30-300 | 30-300 | 10-300 |

| Sesuaikan diameter casing(mm) | f9-35 | f9-35 | f9-28 |

| Ukuran | 1100*500*900mm | 1100*500*900mm | 1100*850*1250mm |

| Berat | 88kg | 100kg | 280kg |

Industri yang Berlaku Mesin Pengikat Sosis Otomatis Gondor

Perusahaan Pengolahan Daging

Berbagai perusahaan produksi sosis, digunakan untuk bundling sosis yang efisien, memastikan sosis memiliki bentuk yang teratur dan panjang yang konsisten, dan memfasilitasi pengemasan dan penjualan selanjutnya.

Usaha Makanan Pra-siap

Jika ada produk makanan sosis yang sudah disiapkan sebelumnya, mesin pengikat kawat dapat memastikan stabilitas penampilan dan kualitas produk, dan cocok untuk produksi skala besar.

Pabrik Makanan Besar

Misalnya, pabrik yang memproduksi makanan sosis seperti sosis ham perlu segera mengikat produk dalam jumlah besar.

Perusahaan Rantai Katering

Bahan sosis diproduksi sendiri untuk pengiriman toko, mesin pengikat kawat dapat memenuhi kebutuhan produksi volume sedang dan memastikan standarisasi bahan.

Pasar Petani

Pedagang yang membuat dan menjual sosis di lokasi dapat menggunakan mesin pengikat kawat untuk meningkatkan citra produk dan efisiensi pemrosesan serta menarik lebih banyak pelanggan.

Bisnis Perorangan

Toko daging kecil dapat meluncurkan layanan pemrosesan sosis yang disesuaikan, dan mesin pengikat kawat dapat berperan.

Perusahaan Ekspor Pangan

Di pasar internasional, ada persyaratan tinggi untuk penampilan dan pengemasan sosis. Mesin pengikat kawat dapat membuat produk memenuhi standar ekspor dan persyaratan estetika dan kualitas pelanggan asing.

Pasar Penyewaan Mesin Makanan

Menyewakan kepada beberapa pelanggan yang memiliki kebutuhan pengolahan sosis jangka pendek (seperti saat festival, peristiwa berskala besar, dll.) tetapi tidak ingin berinvestasi pada peralatan jangka panjang.

Bidang Pengajaran dan Pelatihan Terkait Pangan

Digunakan untuk mengajarkan demonstrasi dan memungkinkan siswa untuk benar-benar mengoperasikan proses pengikatan kawat dalam produksi sosis untuk memahami proses produksi industri makanan.

Keunggulan Kinerja Luar Biasa Mesin Pengikat Sosis Gondor

- Pekerjaan otomatis dapat memproses sosis dalam jumlah besar dalam waktu singkat, seperti mengikat 10-450 sosis per menit.Otomatis dan Efisien

- Mengadopsi motor servo canggih dan sistem kontrol otomatis layar sentuh, otomatis, berkecepatan tinggi, dan stabil.Pengoperasian yang Berkelanjutan dan Stabil

- Dilengkapi dengan antarmuka operasi yang intuitif, akan lebih mudah bagi operator untuk mengatur parameter dan memantau status pengoperasian.Antarmuka Manusia-Mesin

- Badan mesin sepenuhnya dikerjakan dengan mesin CNC, dengan presisi perakitan yang lebih tinggi dan pengoperasian yang lebih stabil.Presisi Tinggi

- Perawatan mesin, layanan perbaikan dan pelacakan.Berlaku untuk Berbagai Jenis Sosis

- Semua bantalan berkecepatan tinggi digunakan, yang dapat diandalkan. Badan mesin sepenuhnya kedap air untuk secara efektif mencegah air masuk ke peralatan listrik.Kokoh dan Tahan Lama

- Mekanisme pengikatan tingkat lanjut, tidak ada kerusakan pada casingnya, dan menjaga keutuhan tampilan sosis.Perlindungan Casing

Pertanyaan yang Sering Diajukan

Membangun Lini Produksi Lengkap

Untuk memaksimalkan efisiensi produksi, Anda dapat mengintegrasikan mesin pengikat sosis Gondor dengan peralatan hulu dan hilir. Misalnya, menghubungkannya ke pengisi sosis pneumatik di ujung depan untuk pengisian dan pengikatan kawat yang terintegrasi. Hubungkan mereka ke oven perokok komersial atau jalur sterilisasi blansing di bagian belakang untuk pemrosesan dan pengawetan rasa. Akhirnya, itu penyegel vakum ruang ganda menyelesaikan penyegelan produk jadi. Hal ini menciptakan jalur produksi yang sepenuhnya otomatis, secara signifikan meningkatkan efisiensi keseluruhan mulai dari produksi hingga pengemasan. Memilih Gondor berarti memilih yang dapat diandalkan, solusi satu atap.