Mesin pengisian paket tas kantong premade otomatis adalah solusi pengemasan otomatis yang efisien dan tepat yang melayani berbagai industri makanan dan non-makanan. Tidak hanya mudah dioperasikan, namun juga dilengkapi dengan layar sentuh multi-bahasa Siemens berukuran 7 inci, memungkinkan sebagian besar parameter diatur dengan mudah. Selain itu, mesin ini menggunakan skala multi-kepala dengan presisi tinggi, yang menjamin akurasi dan stabilitas pengemasan yang sangat baik. Lebih-lebih lagi, peralatan ini mendukung pemberian makan yang sepenuhnya otomatis, dosis, pembuatan tas, dan penyegelan, memungkinkan proses yang efisien. Kantong kemasan dapat dikonfigurasi untuk berdiri tegak atau dilengkapi lubang euro, kait, dan tanggal produksi, meningkatkan fleksibilitas. Sedangkan untuk film kemasan, ini kompatibel dengan tas laminasi, tas PE, tas aluminium, dan kantong kertas dan dapat dibuat menjadi berbagai jenis tas, seperti tas stand-up, tas ritsleting, atau tas datar. Sangat cocok untuk produk berpresisi tinggi dan rapuh—seperti makanan kembung, keripik kentang, jeli, gila, makanan beku, dan biji kopi—mesin pengemas kantong ini menonjol sebagai solusi pengemasan ideal di berbagai industri.

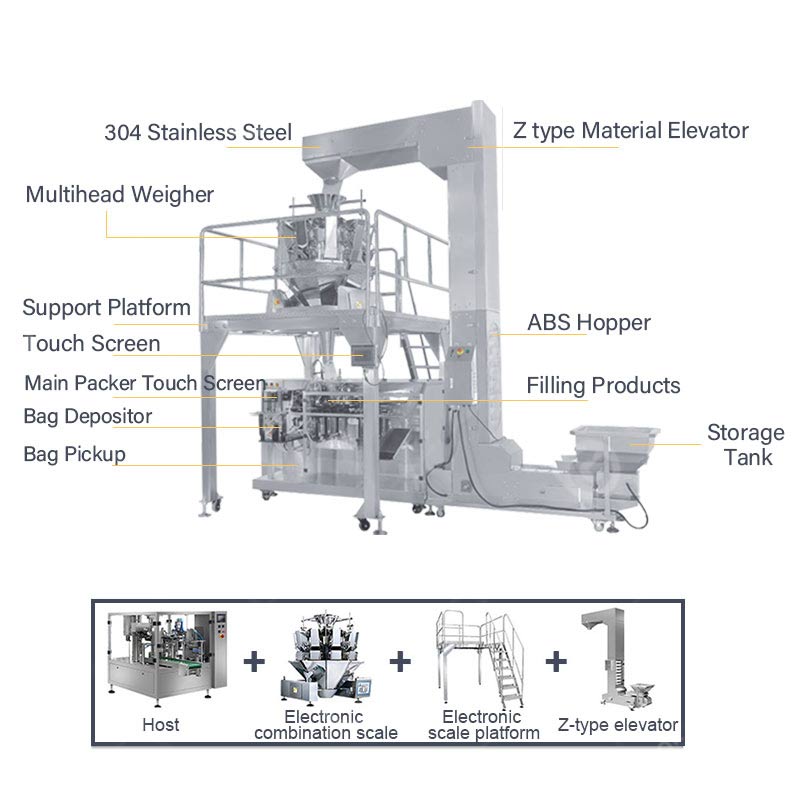

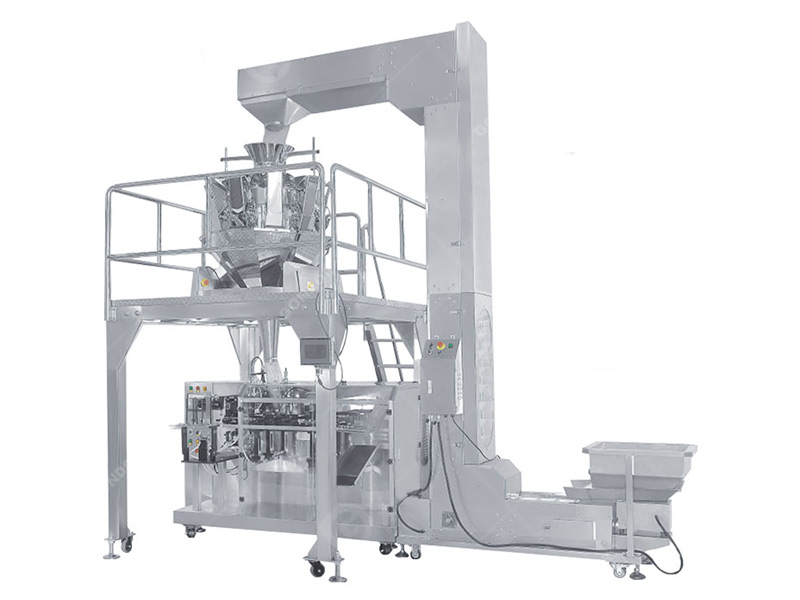

Gondor D-260 Host dengan Skala Elektronik

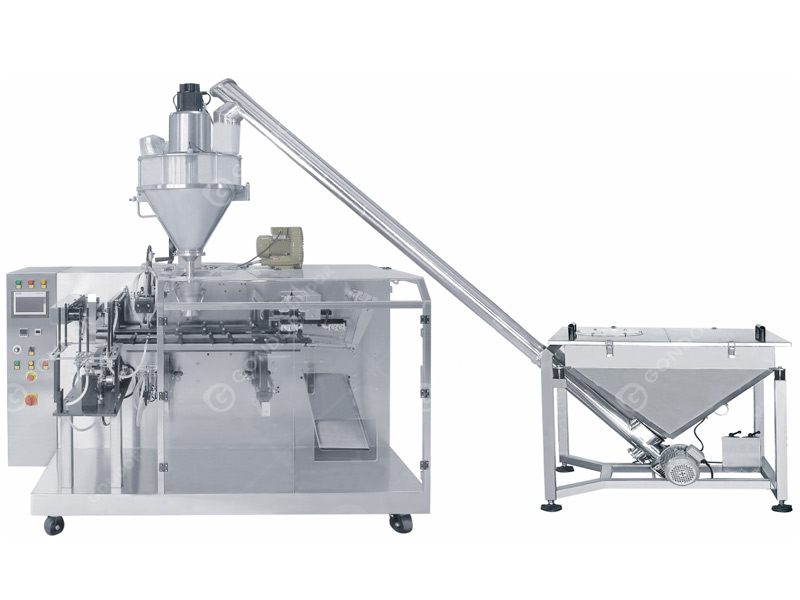

Host Gondor D-260 dengan Sekrup

|

Model

|

GD-DM160

|

GD-DM210

|

GD-DM260

|

|

Ukuran tas

|

L:100-250mm

W: 60-160mm |

L:100-320mm

W: 120-210mm |

L:110-350mm

W: 140-210mm |

|

Rentang Pengukuran

|

10-1000G

|

50-1250G

|

100-1500G

|

|

Kecepatan Pengepakan

|

25-45tas/menit

|

||

|

Kekuatan Memasok

|

380V 3P 50/60hz

|

||

|

Konsumsi Gas

|

≤0,3m³/menit

|

≤0,4m³/menit

|

≤0,5m³/menit

|

|

Jenis Tas

|

Tas berdiri, tas ritsleting, tas datar, misalnya. 3 segel samping, 4 segel samping, tas dengan pegangan lubang berlubang, tas bantal dll.

|

||

|

Ukuran Mesin

|

1700*1050*1100mm

|

21501200*1200mm

|

2450*1350*1300mm

|

Cakupan Pasar Aplikasi yang Luas dari Mesin Pengisian Kantong Premade

Industri berikut dapat menggunakan mesin pengemas pengumpan kantong untuk meningkatkan efisiensi pengemasan, memastikan keakuratan pengemasan, dan beradaptasi dengan berbagai jenis tas kemasan untuk memenuhi kebutuhan pengemasan produk yang berbeda.

Karakteristik Kinerja Unik Mesin Pengisian Kantong Otomatis Gondor

Mesin Pengemas Tas Gondor – Solusi Pengemasan yang Efisien dan Cerdas

Pilih mesin pengisian paket tas kantong premade otomatis Gondor untuk menghadirkan pengalaman pengemasan yang lebih efisien dan akurat untuk produksi Anda! Mesin ini mengadopsi sistem kontrol tiga servo canggih dan pelacakan warna mata elektrik untuk mencapai pengemasan yang efisien dan cepat. Lebih-lebih lagi, peralatan sepenuhnya otomatis, termasuk penempatan tas, penjepitan tas, pengkodean, pembukaan tas, proses pengumpanan material dan penyegelan tas, tanpa intervensi manual, sangat meningkatkan efisiensi produksi. Selain itu, mesin mengumpankan material secara akurat dengan kesalahan akurasi sekecil 0,5g, memastikan bahwa setiap produk tersegel dengan sempurna. Klik di bawah untuk mengirimkan pertanyaan guna mempelajari lebih lanjut tentang bagaimana mesin Gondor dapat membantu pengembangan bisnis Anda!