Dengan berkembangnya tren makan sehat, bihun, bihun, dan bihun populer karena rendah lemak, pencernaan mudah, dan rasanya enak. Kita mesin bihun cocok untuk semua jenis perusahaan pengolahan makanan, dari bengkel kecil hingga pabrik besar, dan dapat mendukung jagung, sorgum, jawawut, kacang hijau, dan bahan baku biji-bijian lainnya untuk memenuhi kebutuhan tradisional Asia, sekaligus memperluas pasar makanan bebas gluten di Eropa dan Amerika Serikat, dan membantu produksi yang efisien dan terdiversifikasi.

| Model |

GD-VRNM-1 |

GD-VRNM-2 |

GD-VRNM-3 |

| Kapasitas |

100kg/jam |

50-60kg/jam |

200kg/jam |

| Kekuatan |

11kw |

9kw |

18.5kw |

| Ukuran |

800*720*1650mm |

1030*460*1460mm |

1120*790*1900mm |

| Berat |

350kg |

100kg |

600kg |

| Ukuran Pengepakan |

900*820*1750mm |

1270*600*1750mm |

1320*990*2100mm |

| Berat Pengepakan |

410kg |

160kg |

710kg |

Skenario Aplikasi Mesin Bihun

Memenuhi kebutuhan Tiongkok, Vietnam, Thailand dan negara-negara lain untuk bihun tradisional, bihun, dan bihun, dan memberikan solusi produksi yang stabil dan efisien.

Menanggapi tren pola makan sehat dan memproduksi mie bebas gluten untuk memenuhi pasar vegetarian dan makanan sehat.

Pasar Afrika dan Amerika Selatan

Mendukung penggunaan tanaman khas lokal sebagai bahan baku, seperti jagung, sorgum, dll., untuk membuat mie gandum yang bergizi.

Fitur Peralatan Luar Biasa Mesin Pembuat Bihun Otomatis

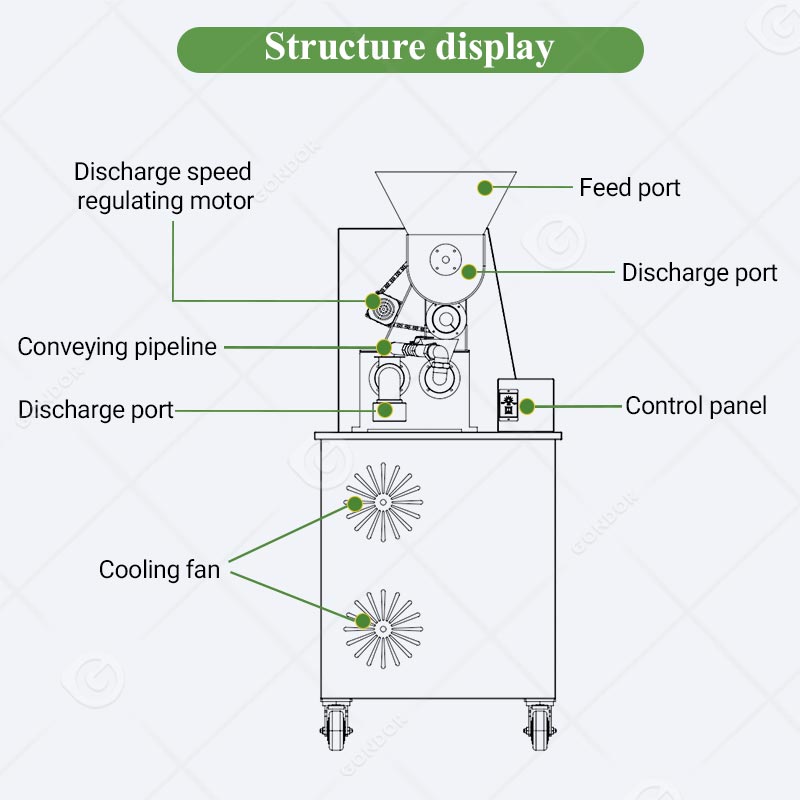

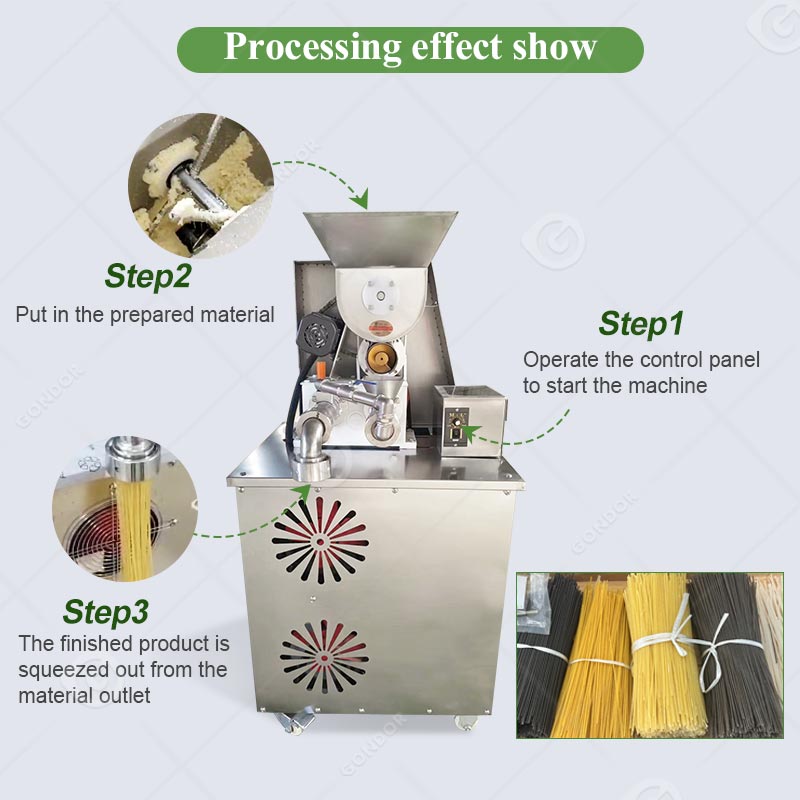

Memasak sendiri & cetakan

Produksi bihun tradisional seringkali memerlukan beberapa langkah seperti mengukus, menguleni, dan pencetakan manual. Mesin Mie Beras kami menggunakan Teknologi Ekstrusi canggih yang memungkinkan bihun secara otomatis matang dan dicetak di dalam mesin, sangat meningkatkan efisiensi produksi dan mengurangi biaya tenaga kerja.

Ketebalan yang Dapat Disesuaikan

Pasar yang berbeda memiliki kebutuhan bihun yang berbeda. Ada yang lebih suka Bihun Tipis dan ada pula yang lebih suka Mie Beras Kental. Mesin ini dilengkapi dengan Cetakan yang Dapat Disesuaikan untuk mendukung produksi berbagai spesifikasi untuk memenuhi kebutuhan pasar yang berbeda.

Sistem Pendingin Udara yang Kuat

Sistem Pendingin Kipas Ganda digunakan untuk mendinginkan bihun dengan cepat setelah cetakan ekstrusi untuk mencegah bihun lengket atau pecah karena suhu yang berlebihan, memastikan bahwa produk jadi memiliki rasa yang lebih baik dan bentuk yang lebih stabil.

Panel Kontrol Cerdas

Panel Operasi Sekali Sentuh yang jelas dan intuitif memungkinkan operator memulai dengan cepat tanpa pelatihan yang rumit. Peralatan tersebut memiliki otomatisasi tingkat tinggi, mengurangi kesalahan manusia dan meningkatkan efisiensi produksi.

Motor Frekuensi Variabel

Peralatan ini dilengkapi dengan Motor Kecepatan Konversi Frekuensi, yang secara akurat dapat mengontrol kecepatan pengumpanan untuk memastikan keluarnya bihun secara merata dan menghindari masalah produksi yang disebabkan oleh pemberian pakan yang tidak merata.

Serbaguna dan Multi-Fungsional

Selain memproduksi bihun dan bihun, mesin ini juga dapat mengolah mie dingin, kue beras manis, mie jagung dan makanan lainnya, mewujudkan integrasi multi-fungsi, membantu perusahaan mengoptimalkan produksi dan memperluas kategori produk.

Mengapa Memilih Mesin Bihun Beras dari Gondor?

Efisiensi Tinggi Ramah PenggunaTahan lama & Stabil Dapat disesuaikanHemat Energi

Pengoperasian otomatis sangat meningkatkan kapasitas produksi dan mengurangi biaya tenaga kerja.

Sistem kontrol cerdas, mulai cepat, tidak perlu teknisi profesional.

Terbuat dari bahan berkualitas tinggi, operasi yang stabil dan umur panjang.

Berbagai cetakan tersedia untuk memenuhi kebutuhan pasar yang berbeda.

Motor efisiensi tinggi, konsumsi energi yang rendah, dan mengurangi biaya produksi.

Rekomendasi yang Diperluas – Dengan Peralatan Pengolahan Makanan Lainnya

Jika Anda tertarik dengan mesin bihun, atau ingin lebih memperluas lini produksi, kami juga menyediakan berbagai peralatan pengolahan makanan terkait, seperti:

- Mesin Pengaduk Adonan: Cocok untuk produksi mie, roti kukus, bungkus pangsit dan produk mie lainnya.

- Lini Produksi Makaroni: Menghasilkan berbagai jenis pasta seperti spageti, makaroni, dan mie lebar.

- Pemotong Sayur: Cocok untuk memotong dan mengolah sayuran untuk meningkatkan efisiensi pengolahan makanan.

Selamat datang untuk menghubungi kami untuk informasi produk lebih lanjut dan solusi khusus! Jadikan pengolahan makanan Anda lebih efisien dan beragam, dan membantu perusahaan bergerak menuju pasar global!