Mesin Permen Roller Batch Gondor

Itu batch roller candy machine dirancang khusus untuk produksi permen strip. Terbuat dari baja tahan karat yang menebal, itu aman dan tahan lama, Menawarkan kebisingan rendah dan efisiensi tinggi, which significantly reduces labor intensity. Untuk beroperasi, cukup tempatkan massa gula pada suhu yang sesuai ke dalam roller bed yang diisolasi panas. Peralatan kemudian menyesuaikan jarak dan kecepatan rol strip, memungkinkan massa gula ditarik dengan mulus ke dalam kolom gula berbentuk kerucut dan kemudian diregangkan menjadi potongan tipis untuk dicetak. Lebih-lebih lagi, ini kompatibel dengan berbagai mesin cetak. Dengan pengoperasian yang mudah, fungsi serbaguna, dan dukungan untuk pekerjaan yang berkelanjutan, mesin ini sangat meningkatkan efisiensi produksi. Keseluruhan, peralatan ini adalah asisten yang efisien dalam produksi permen strip, membantu perusahaan mengoptimalkan proses mereka.

|

Nama

|

Kekuatan(kw)

|

Berat(kg)

|

Dimensi Eksternal(mm)

|

Kapasitas

|

|

Rol batch

|

4.75

|

450

|

2100*600*1150

|

150-300 potongan/menit

|

|

Pengukur tali

|

3.3

|

430

|

1400*800*1300

|

Area Permintaan Permen Roller Batch Gondor

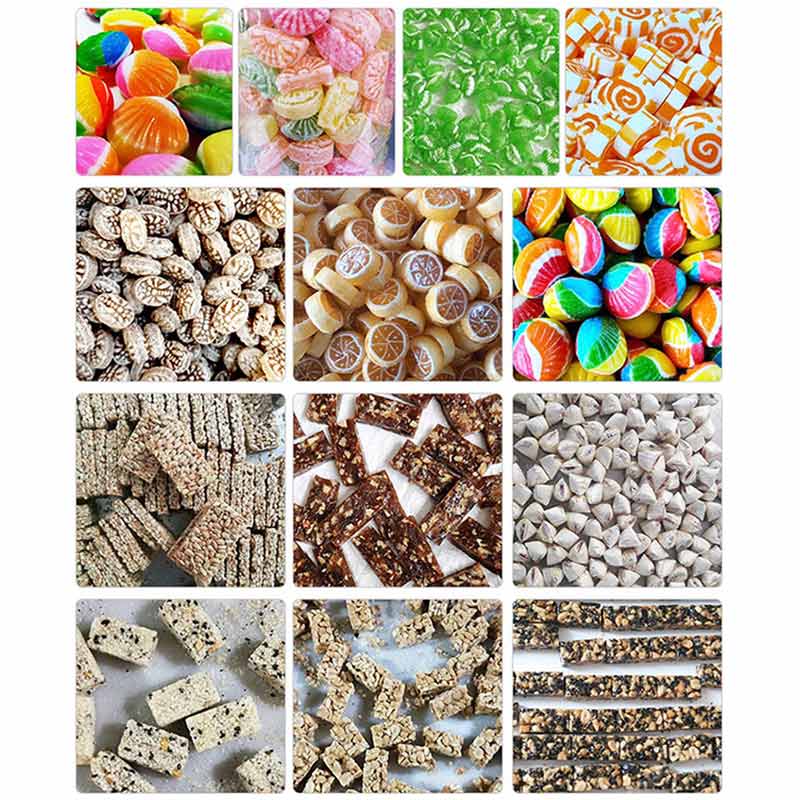

Roller batch yang efisien ini banyak digunakan di berbagai bidang untuk memenuhi kebutuhan produksi yang berbeda karena pengoperasiannya yang mudah, penerapan dan kemampuan beradaptasi yang kuat pada berbagai mesin cetak. Berikut ini adalah area permintaan utama untuk peralatan ini:

Keunggulan Kinerja Luar Biasa dari Mesin Batch Roller Gondor

Roller batch Gondor banyak digunakan dalam bidang produksi permen dengan keunggulan efisiensinya yang tinggi, daya tahan, pengoperasian yang mudah dan multifungsi, membantu perusahaan untuk secara signifikan meningkatkan efisiensi produksi dan konsistensi kualitas produk. Sangat cocok untuk berbagai peralatan pencetakan dan mendukung pengoperasian berkelanjutan, menjadikannya pilihan ideal bagi perusahaan produksi permen untuk mengoptimalkan aliran proses, mengurangi biaya dan meningkatkan daya saing pasar.

Mesin Permen Roller Batch Gondor – Pilihan Terbaik untuk Produksi yang Efisien

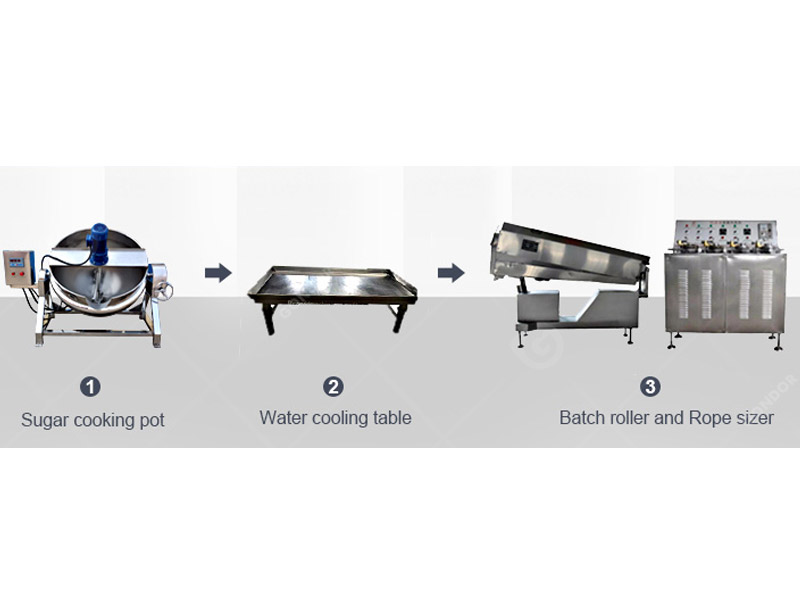

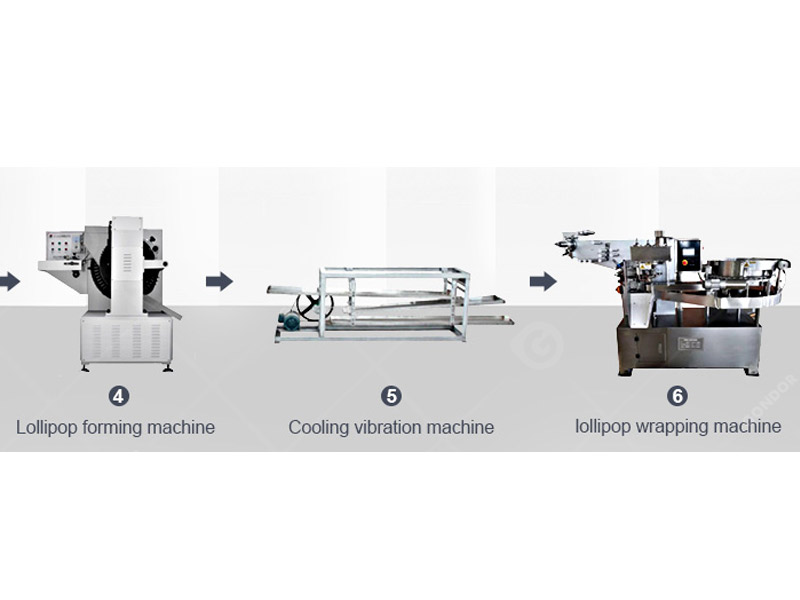

If you are looking for professional equipment to improve the production efficiency of candy, Gondor batch roller candy machine is your ideal production partner. The equipment is made of food-grade thickened stainless steel, dan pengoperasiannya sederhana dan intuitif. The extension and shaping of candy bars can be easily completed by accurately adjusting the distance and speed of rollers, and it can be smoothly docked with various molding machines, flexibly adapting to the production requirements of different scales and processes.

If you want to build a complete candy production line, you can use this equipment with the ketel jaket uap to realize the seamless connection from syrup boiling to candy bar forming. Bisa juga dihubungkan dengan a mesin pembentuk lolipop to efficiently produce lollipop products with the same shape. Choosing the Gondor rolling and drawing machine is not only to introduce a device, but also to create a stable, flexible and efficient candy production process. Contact us now to get customized solutions and exclusive quotations!