Pengering Belt Konveyor Mesh Berkelanjutan yang Efisien dan Hemat Energi

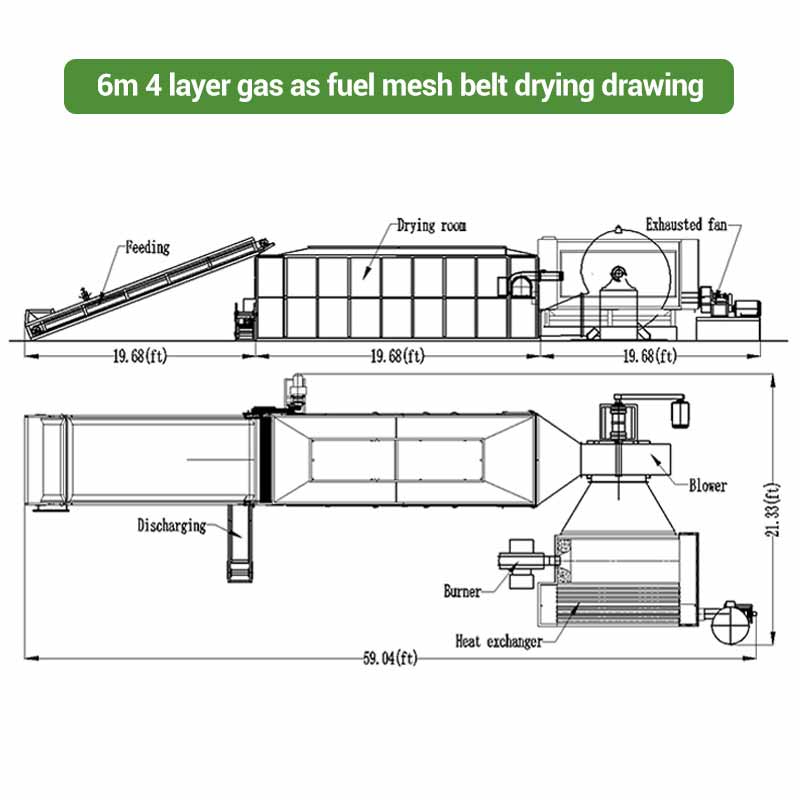

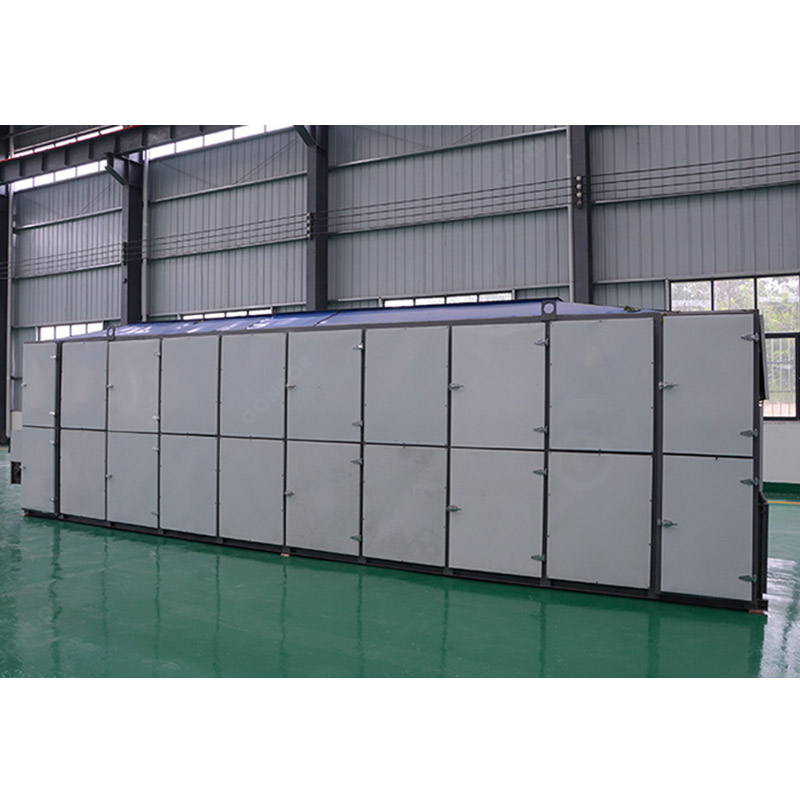

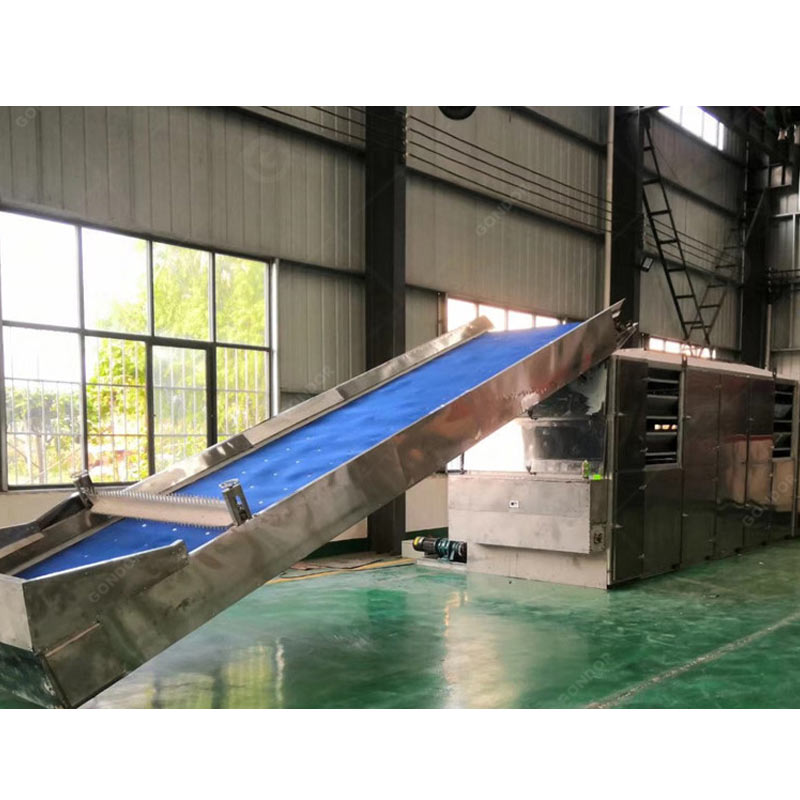

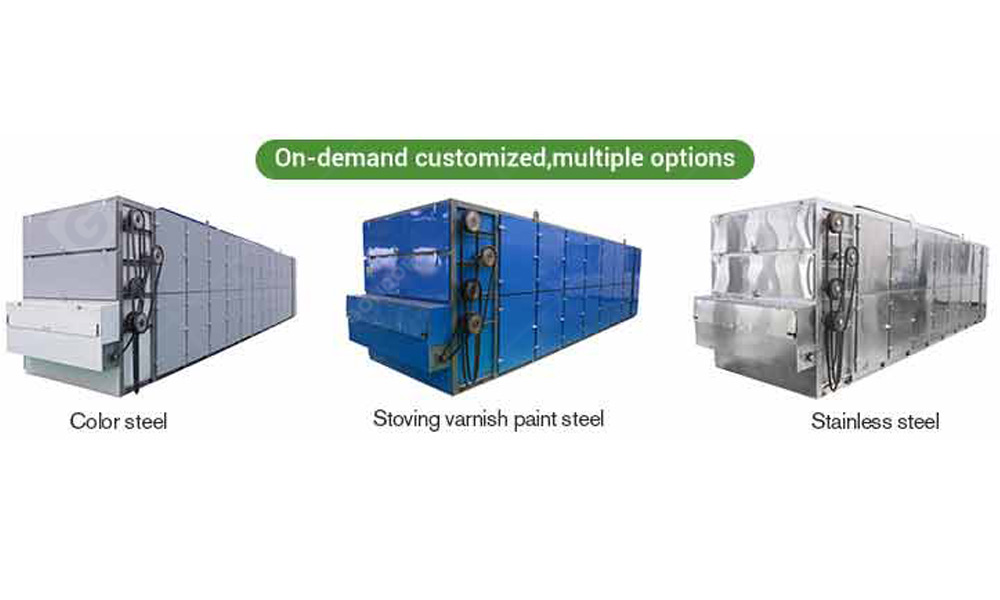

Pengering sabuk konveyor mesh kontinyu adalah efisien, solusi pengeringan hemat energi yang menggunakan udara panas sebagai media pengeringan. Dalam sistem ini, bahan tersebar secara merata dan terus menerus disalurkan melalui beberapa lapisan sabuk jaring baja tahan karat. Saat udara panas menembus material dari lapisan bawah hingga lapisan atas, pengeringan yang cepat dan menyeluruh tercapai. Sementara itu, kelembaban dibuang dari atas, dan produk kering diangkut keluar melalui konveyor pelepasan. Peralatan tersebut mendukung berbagai sumber panas, termasuk listrik, gas, dan solar, memungkinkan pengguna untuk memilih opsi yang paling nyaman dan ekonomis. Lebih-lebih lagi, panas didistribusikan secara merata untuk memastikan proses pengeringan bebas polusi, dan suhu, kelembaban, dan volume udara semuanya dapat disesuaikan dengan cerdas. Selain itu, rantainya yang berkekuatan tinggi tahan aus, sementara layar baja tahan karat food grade memastikan keamanan dan daya tahan. Pengering ini sangat cocok untuk pengolahan sayuran dan buah-buahan skala kecil, menjadikannya pilihan ideal untuk produksi skala kecil dan menengah.

| Model | GD-8 | GD-9 | GD-10 | GD-12 |

| Lapisan | 4 lapisan, 5 lapisan, 6 lapisan | |||

| Ketebalan bahan | 10-70mm | |||

| Suhu pengeringan | 40~120°C | |||

| Mengurangi kelembapan | 75% ke 8% (Disesuaikan) | |||

| Waktu pengeringan | 0.5-5 jam | |||

| Kekuatan mesin utama | 1.5kw | 1.5kw | 2.2kw | 3kw |

| Kipas angin udara panas | 15kw | 15kw | 22kw | 22kw |

| Pelepasan konveyor | B500(0.12kw) | B500(0.12kw) | B500(0.12kw) | B500(0.12kw) |

| Catatan:Parameter di atas adalah untuk referensi, kami menyesuaikan mesin sesuai dengan kebutuhan pelanggan dan memberikan solusi terbaik. | ||||

Pasar Utama yang Berlaku untuk Pengering Sabuk Gondor Mesh

Berlaku untuk mengeringkan produk pertanian seperti sayuran, buah-buahan, rempah-rempah dan teh beraroma, meningkatkan nilai tambah produk pertanian dan memperpanjang umur simpan.

Banyak digunakan dalam mengeringkan makanan seperti daging dan kacang-kacangan untuk memastikan kebersihan makanan dan efisiensi pengeringan.

Cocok untuk produksi batch kecil, memberikan solusi pengeringan yang nyaman bagi petani dan pabrik pengolahan keluarga.

Sangat cocok untuk perusahaan dengan kapasitas pemrosesan harian di bawah 5 ton, memenuhi kebutuhan produksi kecil dan menengah dan memenuhi persyaratan perlindungan lingkungan.

Karena efisiensinya yang tinggi, karakteristik hemat energi dan perlindungan lingkungan hijau, itu memenuhi persyaratan kebijakan perlindungan lingkungan, dan beberapa daerah juga dapat memperoleh subsidi pembelian mesin.

Mendukung berbagai pilihan sumber panas, seperti biomassa dan energi baru, sejalan dengan tren perkembangan energi baru.

Keunggulan Kompetitif Signifikan dari Pengering Sabuk Berkelanjutan Grup Gondor

Efisiensi Tinggi dan Hemat Energi – Pengering Sabuk Konveyor Gondor

Pengering sabuk konveyor jaring kontinu Gondor memberi Anda efisiensi, solusi pengeringan berkelanjutan dan hemat energi. Peralatan ini mengadopsi transmisi sabuk jaring baja tahan karat multi-lapis, dan sirkulasi udara panas menembus lapisan bahan secara merata untuk memastikan efek pengeringan yang cepat dan menyeluruh. Ini mendukung berbagai jenis sumber panas seperti energi listrik, gas dan minyak solar, dan dilengkapi dengan kontrol suhu cerdas dan sistem penyesuaian kelembapan untuk mewujudkan pengoperasian yang sepenuhnya otomatis dan memenuhi persyaratan perlindungan lingkungan dan produksi bersih. Ini sangat cocok untuk pemrosesan pengeringan sayuran skala besar, buah-buahan, Obat-obatan herbal Cina dan produk daging, yang secara efektif dapat meningkatkan produktivitas dan mengurangi konsumsi energi.

Jika Anda memiliki persyaratan yang lebih tinggi untuk retensi bahan aktif dan bentuk bahan, Anda dapat bekerja sama lebih lanjut dengan a mesin pengering beku vakum untuk membentuk lini produksi pengeringan lengkap dari pengeringan konvensional hingga pengeringan beku kelas atas, mencakup kebutuhan produk dan skenario aplikasi yang lebih luas. Selamat datang untuk menghubungi kami segera untuk mendapatkan skema pengeringan yang disesuaikan dan dukungan seleksi profesional, dan memulai tahap baru produksi pengeringan yang efisien dan cerdas!