Mesin Pembuat Pelet Es Kering Gondor

Mesin pembuat pelet es kering adalah sejenis peralatan yang khusus digunakan untuk pembuatan pelet es kering. Itu dapat mengubah karbon dioksida cair (CO2) menjadi pelet es kering untuk memenuhi kebutuhan pembekuan suhu rendah, kelestarian, efek khusus dan pembersihan di berbagai industri dan bidang aplikasi. Mesin ini memiliki kinerja yang efisien dan stabil, menyediakan solusi es kering yang nyaman dan efisien untuk berbagai industri, dan merupakan asisten yang ampuh untuk produksi dan kehidupan modern.

Spesifikasi Granulator Es Kering

| Model | Kemampuan produksi | Spesifikasi es kering | Kepadatan es kering | Rasio konversi co2 cair dan padat | Kekuatan total | Berat peralatan | Dimensi keseluruhan |

| GD-DIPM50 | 40-50 kg/jam | Φ3mm,Φ16mm | 1550kg/m³ | ≥42% | 3kw | 175kg | 100×48×102cm |

| GD-DIPM100 | 100kg/jam | Φ3mm,Φ10mm,

Φ16mm, |

1550kg/m³ | ≥42% | 4kw | 380kg | 145×60×142cm |

| GD-DIPM120 | 120-180kg/jam | 125×105×70/80mm | 1450-1550kg/m³ | ≥42% | 4.5kw | 360kg | 128×56×134cm |

| GD-DIPM150 | 150kg/jam | Φ3mm,Φ16mm, Φ19mm |

1550kg/m³ | ≥42% | 7.5kw | 3600kg | 165×65×168cm |

| GD-DIPM300 | 300-350kg/jam | Φ3mm,Φ16mm, Φ19mm |

1550kg/m³ | ≥42% | 8kw | 1100kg | 165×115×168cm |

| GD-DIPM500 | 500-550kg/jam | Φ3mm,Φ16mm, Φ19mm |

1550kg/m³ | ≥42% | 18.5kw | 1650kg | 178×135×180cm |

Industri Terkait Menggunakan Mesin Pembuat Es Kering Gondor

Selama transportasi jarak jauh dan penyimpanan makanan, pelet es kering dapat memberikan lingkungan suhu rendah yang stabil dan tahan lama untuk menjamin kesegaran dan rasa makanan serta memperpanjang umur simpan makanan.

Es kering dapat digunakan untuk membekukan dan mengeringkan obat-obatan serta mengawetkan sampel biologis. Es kering juga merupakan kebutuhan selama pengangkutan produk medis seperti vaksin dan produk darah, yang dapat menjamin kualitas dan keamanan produk tersebut selama transportasi.

Ia memiliki keunggulan unik dalam membersihkan noda minyak pada permukaan papan sirkuit terpadu, komponen elektronik dan peralatan petrokimia. Ini menghindari polusi lingkungan dan masalah korosi peralatan yang mungkin disebabkan oleh metode pembersihan tradisional.

Sebagai media pendingin yang efisien, pelet es kering digunakan untuk mendinginkan peralatan listrik, seperti transformator, kabel, dll.. Selain itu, juga dapat digunakan untuk menghilangkan debu dan kotoran pada permukaan peralatan listrik untuk meningkatkan kinerja insulasi dan keamanan peralatan.

Dalam penangkapan karbon, pemanfaatan dan penyimpanan (CCUS) teknologi, alat pelet es kering dapat mengubah karbon dioksida yang ditangkap menjadi pelet es kering, yang mudah disimpan dan diangkut, dan mengurangi emisi gas rumah kaca.

Keunggulan Penggunaan Mesin Pembuat Pelet Es Kering Gondor

- Ini dapat dengan cepat mengubah gas karbon dioksida menjadi pelet es kering, sangat meningkatkan efisiensi produksi. Ini dapat memenuhi kebutuhan produksi pada skala yang berbeda dan menghemat waktu dan biaya bagi perusahaan.Produksi yang Efisien

- Penggunaan gas karbon dioksida sebagai bahan baku mengurangi pencemaran terhadap lingkungan. Pada saat yang sama, es kering akan langsung menyublim menjadi gas karbon dioksida setelah digunakan, dan tidak akan menghasilkan limbah apa pun, yang memenuhi persyaratan perlindungan lingkungan.Penghematan Energi dan Perlindungan Lingkungan

- Cocok untuk berbagai bidang, seperti pengawetan makanan, pembersihan industri, efek panggung, dll.. Memberikan solusi es kering yang nyaman dan efisien untuk berbagai industri, dengan nilai praktis yang tinggi.Aplikasi Luas

- Kebanyakan pelet es kering memiliki parameter yang dapat disesuaikan, memungkinkan pengguna membuat pelet es kering dengan berbagai ukuran dan bentuk sesuai kebutuhan.Parameter yang Dapat Disesuaikan

- Biasanya mesin-mesin tersebut memiliki beberapa tingkat fitur keselamatan untuk menjamin keamanan dan keandalan peralatan untuk melindungi operator dari bahaya gas CO2 dan mesin.Aman dan Terpercaya

- Stasiun pompa hidrolik dan modul pembentuk pelet keduanya sudah terpasang, yang mengurangi jejak peralatan di satu sisi, dan menghindari pengaruh debu di sisi lain.Komponen Bawaan

Proses Penggunaan Mesin Pelet Es Kering Gondor

Pertama, Anda perlu menyiapkan bahan baku es kering, biasanya karbon dioksida cair (CO2), yang biasanya disimpan dalam tangki gas karbon dioksida.

Gunakan pipa atau selang gas bertekanan tinggi yang sesuai untuk menghubungkan tangki gas CO2 ke granulator es kering. Pastikan sambungan aman untuk mencegah kebocoran gas.

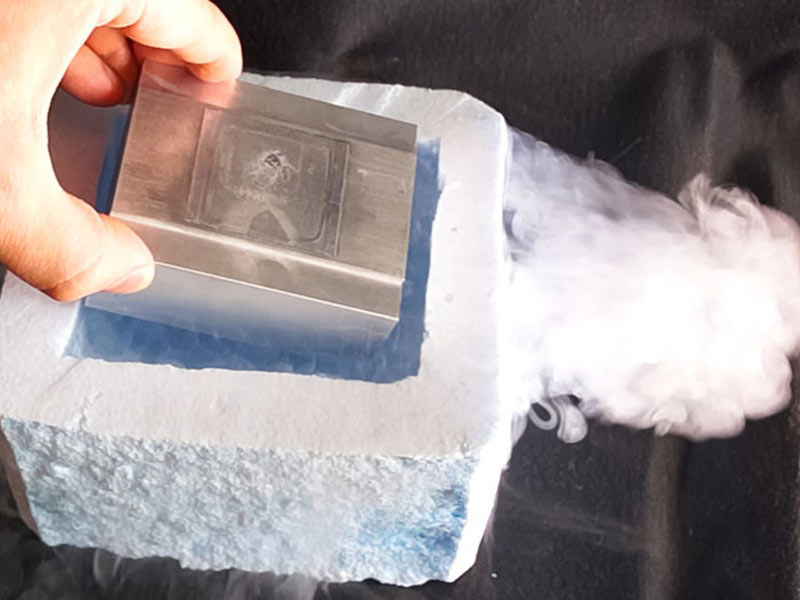

Nyalakan mesin es kering dan atur parameter yang diperlukan untuk mulai membuat pelet es kering. Biasanya, mesin secara otomatis mengontrol proses pendinginan dan granulasi. Es kering keluar dari saluran keluar es.

Setelah produksi selesai, tutup katup tangki bensin CO2 dan hentikan pengoperasian mesin es kering. Tunggu beberapa saat untuk memastikan gas CO2 yang tersisa di sistem sudah terlepas atau dibuang.

Artefak Pelet Es Kering – Mesin Pembuat Pelet Es Kering Gondor Akan Segera Hadir

Pelanggan yang terhormat, Mesin pembuat es kering Gondor adalah pilihan ideal Anda! Banyak digunakan dalam makanan, medis, bidang industri dan lainnya, memberi Anda solusi suhu rendah dan metode pembersihan yang efisien. Tepatnya memproduksi pelet es kering dengan kualitas yang dapat diandalkan. Memilih berarti memilih efisiensi dan profesionalisme. Datang dan pesan, biarkan mesin pembuat pelet es kering Gondor menambah dukungan kuat untuk bisnis Anda!

Fitur Mesin Pelet Es Kering Gondor

Efisiensi Tinggi dan Hemat Energi:

Granulator es kering modern sebagian besar mengadopsi sistem kontrol otomatis PLC, memungkinkan produksi berkelanjutan dengan konsumsi energi rendah dan efisiensi tinggi.

Ukuran Pelet yang Dapat Disesuaikan:

Dengan mengganti cetakan, pelet es kering dengan diameter berbeda (misalnya, 3mm, 6mm, 16mm) dapat diproduksi untuk memenuhi berbagai kebutuhan aplikasi.

Struktur Kompak dan Pengoperasian yang Mudah:

Sebagian besar mesin mengadopsi struktur tertutup bergaya kabinet atau baja tahan karat, menempati sedikit ruang, dengan kebisingan rendah dan perawatan mudah.

Aman dan Terpercaya:

Peralatan tersebut biasanya dilengkapi dengan sistem keselamatan seperti pelindung suhu rendah, pemantauan tekanan, dan alarm otomatis untuk memastikan pengoperasian yang stabil.

Ramah Lingkungan dan Bebas Polusi:

Pelet es kering langsung menyublim menjadi gas CO₂ saat digunakan, tidak meninggalkan residu dan tidak menimbulkan polusi, menjadikannya cocok untuk industri dengan kebutuhan tinggi seperti makanan dan obat-obatan.