Pengenalan Jalur Pencucian Telur Gondor

Mesin pencuci telur adalah solusi profesional yang dirancang untuk membersihkan dan memproses telur dalam jumlah besar, menjadikannya ideal untuk peternakan unggas, pabrik makanan, dan pemasok telur. Jalur ini dilengkapi dengan tangki air, ban berjalan, sistem semprotan, kuas, dan bagian pengeringan untuk menghilangkan kotoran secara menyeluruh, kotoran, dan bakteri dari permukaan cangkang telur.

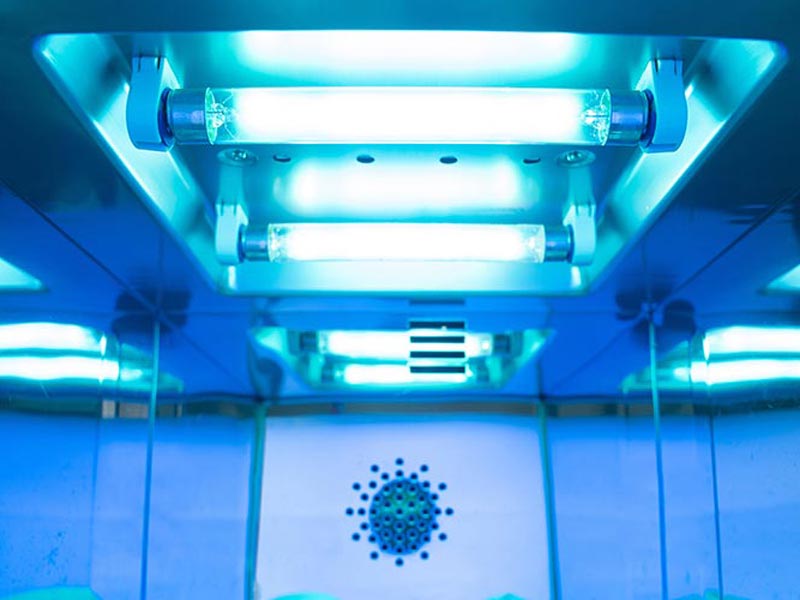

Selama operasi, telur secara otomatis dimasukkan ke dalam saluran dan melewati perendaman, penyemprotan, dan penyikatan lembut untuk pembersihan mendalam. Kemudian dikeringkan di udara dengan sirkulasi hangat, diperiksa dengan deteksi optik untuk menghilangkan telur yang retak atau cacat, dan dapat disterilkan lebih lanjut. Akhirnya, telur dapat dinilai dan dikemas, memastikannya higienis, aman, dan siap didistribusikan ke pasar.

Parameter Lini Produksi Pencucian Telur Gondor

| Nama Produk | Catu Daya | Pasokan Udara | Keluaran Peralatan |

| Mesin Pemuatan Telur | Catu Daya Tambahan DC24V, 60W | 0.6MPa, 10L/mnt | 2,700 – 20,000 telur/jam, dapat disesuaikan kecepatannya |

| Mesin Penata Telur

(Port Tunggal Horisontal) |

Catu Daya Tambahan DC24V, 60W | Maksimum 10,800 telur/jam, dapat disesuaikan kecepatannya | |

| Mesin Penata Telur | Catu Daya Tambahan DC24V, 60W | Maksimum 5,400 – 16,200 telur/jam, dapat disesuaikan kecepatannya | |

| Mesin Pengumpul Telur | Catu Daya Tambahan DC24V, 60W | 2,700 – 20,000 telur/jam, dapat disesuaikan kecepatannya | |

| Pencucian Telur Terintegrasi,

Mesin Pengeringan dan Inspeksi Optik (Termasuk Lampu UV) |

AC220V, 1PH (1 Fase), 1.7Kw | Maksimum 5,400 – 16,200 telur/jam, dapat disesuaikan kecepatannya | |

| Mesin Modular

(Pencucian Telur, Pengeringan dan Inspeksi Optik Opsional) |

AC220V, 1PH (1 Fase), 0.15 – 1.5Kw | Maksimum 5,400 – 16,200 telur/jam, dapat disesuaikan kecepatannya |

Aplikasi Lini Produksi Pencucian Dan Pengolahan Telur Gondor

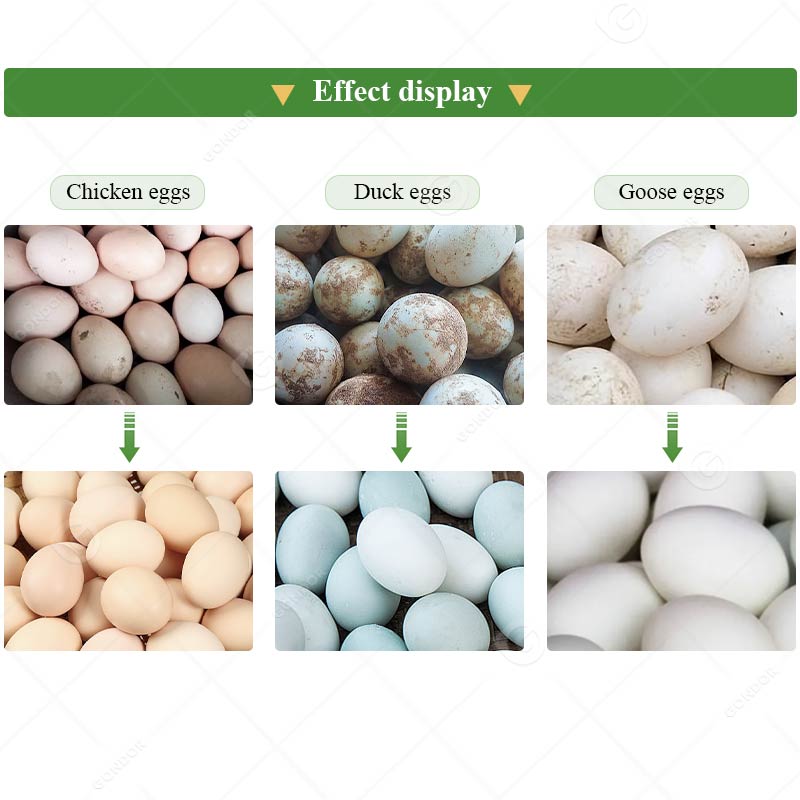

Garis pembersih telur ini sangat ideal untuk peternakan unggas, pemasok telur, pabrik pengolahan makanan, supermarket, dan dapur pusat. Bisa mengolah telur ayam, telur bebek, dan telur berkerang serupa lainnya, membuatnya bersih dan kering untuk pengemasan atau pemrosesan lebih lanjut.

Struktur Jalur Pengolahan Telur Gondor

Dirancang untuk pemrosesan telur profesional, garis terintegrasi ini digabungkan 304 konstruksi baja tahan karat, pembersihan yang lembut namun efektif, dan kontrol kualitas multi-tahap untuk memastikan keamanan, telur berkualitas tinggi dengan alur kerja yang disederhanakan.

Fitur Peralatan Pengolahan Telur Gondor

- Desain Terintegrasi: Mencuci dan mengeringkan dalam satu unit kompak, menghemat ruang dan tenaga kerja.

- Pembersihan Lembut: Rol sikat lembut dan semprotan air menghindari kerusakan telur.

- Pengeringan yang Efisien: Sistem udara hangat memastikan pengeringan cepat dan seragam.

- Standar Higienis: Terbuat dari baja tahan karat, mudah dibersihkan dan dirawat.

- Hemat Energi: Dilengkapi dengan daur ulang air dan pemanasan udara yang optimal.

Peralatan Pendukung yang Direkomendasikan Untuk Lini Produksi Pembersihan Dan Pengolahan Telur

Untuk membangun bengkel pengolahan telur proses penuh yang lebih efisien, peralatan pendukung inti berikut dapat dicocokkan:

Melalui integrasi yang mulus antara lini produksi pembersihan dan pemrosesan telur dengan peralatan pendukung, ini mencapai operasi otomatis satu atap dari pembersihan telur, pemisahan putih telur dan kuning telur yang tepat untuk pengemasan produk jadi secara kuantitatif. Baik untuk pengolahan telur segar, persiapan bahan kue, atau produksi produk olahan seperti mayones dan bubuk protein telur, peralatan pembersihan dan pemrosesan telur kami yang lengkap menyediakan pabrik Anda yang higienis, efisien, dan solusi pemrosesan yang dapat disesuaikan dengan banyak permintaan. Hubungi kami sekarang untuk mendapatkan paket yang disesuaikan!